Your display costs seem unpredictable, hurting your campaign's profitability. To gain control, you must understand the four core factors that truly determine the final price of your retail displays.

The main cost drivers for retail-ready packaging1 and displays are structural design2, material selection3, print complexity4, and logistics. Each factor involves strict retailer compliance5, which significantly impacts total project expense, not just the unit price of the display itself.

When I first started designing displays over a decade ago, many clients focused only on the per-unit cost. They would say, "Your competitor is ten cents cheaper per display." But what they didn't see was the bigger picture. Major retailers like Walmart, Costco, and Target aren't just buying a cardboard display; they are buying a guarantee. They are buying compliance, in-store efficiency, and ultimately, a program that helps them sell more of your product. A cheap display that fails, requires extra labor, or doesn't meet their guidelines is far more expensive in the long run. My job is to help you see the total landed cost6 and engineer a solution that works from our factory floor in China all the way to the retail floor in the United States. Let's break down what really goes into the cost.

How Does Structural Design and Load Capability Affect Display Costs?

Your display failed in-store, causing a mess and product damage. This leads to retailer chargebacks and hurts your brand's reputation. Proper structural engineering from the start prevents these costly failures.

Structural design directly impacts POP display cost drivers by determining the amount and type of material needed to meet retailer load requirements. A weak design fails testing, forcing expensive redesigns, while a strong, efficient design ensures compliance and prevents in-store failure.

Dive Deeper: Engineering for the Retail Environment

Structural engineering is where cost control truly begins. It’s not just about making a display that looks good; it's about creating a structure that survives the entire supply chain and performs perfectly in a specific retail environment7. A display destined for Costco has fundamentally different requirements than one for Target.

I once worked with a beverage brand that wanted to save money by using a simpler, lighter structure for a pallet display. The design looked fine on paper. However, it failed the crucial load and transit tests required by Sam's Club. We had to go back to the drawing board, adding internal supports8 and reinforcement. The redesign and new prototype added two weeks to the timeline and increased the unit cost by 15%. Had we engineered it correctly for the retailer from the start, we would have saved both time and money.

This is why understanding retailer-specific demands9 is non-negotiable.

Retailer Engineering Requirements

| Retailer | Key Structural Requirement | Cost Implication |

|---|---|---|

| Walmart & Sam's Club | Strict load rating (e.g., 5x product weight), tip resistance, and transit testing (ISTA). | Requires robust internal supports8, potentially thicker board, and rigorous pre-testing. |

| Costco | Must handle very heavy, bulk SKUs on a specific pallet footprint. Must be "forklift proof." | Demands heavy-duty structural elements, often double-wall board, and integrated pallet design. |

| Target | Balances stability with a clean, premium presentation. Focus on shopper interaction and safety. | Often requires clever engineering to hide structural supports while ensuring the display is stable. |

Ultimately, great structural design2 isn't about adding more cardboard; it's about using the right cardboard in the right places to achieve compliance at the most efficient cost.

How Does Material Selection and Board Grade Influence Your Final Cost?

You chose the cheapest material for your cardboard display. It looked fine at first, but it sagged and collapsed under the product's weight in a humid warehouse, creating a total loss.

Material choice, specifically the corrugate board grade10, is a primary cardboard display cost. Using a grade that's too weak leads to failure and retailer rejection. Over-engineering with a grade that's too strong needlessly increases your unit cost by 20-40%.

Dive Deeper: Balancing Strength, Cost, and Compliance

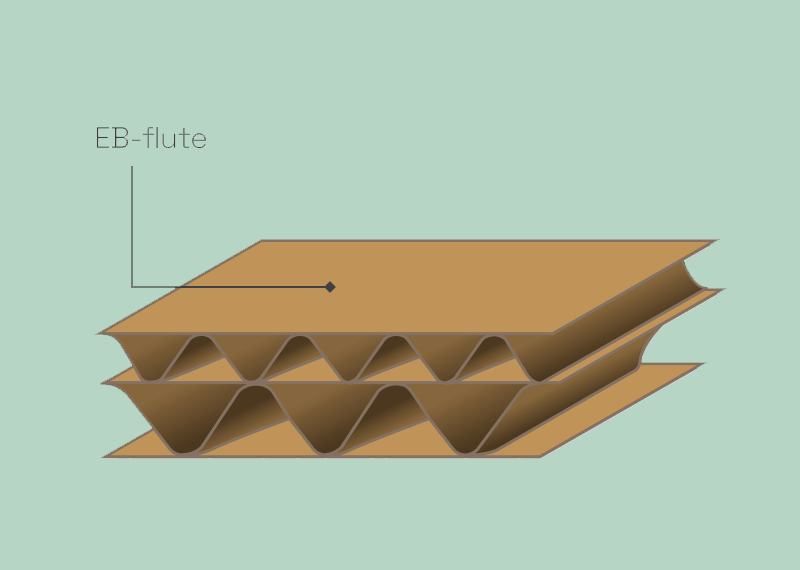

When we talk about "cardboard," we're really talking about corrugated fiberboard. The strength and cost of this material are determined by two things: the paper liners on the outside and the wavy, arched paper (the "flute") sandwiched in between. You don't need to be a paper scientist, but you do need to understand that not all cardboard is created equal.

A common mistake I see is brands specifying a board grade that is far too strong for the application. They've had a display fail in the past, so their reaction is to demand the thickest, strongest board available. This is what we call over-engineering. For a lightweight CPG product, using a heavy-duty double-wall board when a standard 200# single-wall board would pass all tests is like using a sledgehammer to crack a nut. It works, but it's wasteful and unnecessarily drives up your retail-ready packaging costs.

Common Board Types and Their Uses

| Board/Flute Type | Primary Characteristic | Best Use Case | Cost Impact |

|---|---|---|---|

| E-Flute | Very thin, excellent print surface | Small boxes, displays needing a high-quality litho finish. | Moderate |

| B-Flute | Good balance of strength and printability. | The "workhorse" for many standard PDQ trays and displays. | Standard |

| C-Flute | Thicker, with better stacking strength. | Shipper boxes, displays needing more vertical support. | Standard |

| BC-Flute (Double Wall) | Very strong and durable. | Pallet displays, heavy products (beverages, hardware). | High |

How Much Does Print Complexity Add to Retail Display Costs?

Your display's graphics looked great on your computer screen but appeared faded and cheap in the store. Poor printing devalues your brand and fails to attract the shoppers you paid to reach.

Print complexity is a significant cost factor. High-resolution lithographic printing is more expensive upfront than basic flexographic printing12 due to tooling and setup. The number of colors, ink coverage, and special finishes all add to the final price per unit.

Dive Deeper: Choosing the Right Visual Impact for Your Budget

The visual appeal13 of your display is critical, but the method used to achieve that look has major cost implications. As a corrugate display manufacturer, we primarily use two methods: flexography (flexo) and lithography (litho-lamination).

Flexo printing is like using a giant rubber stamp to apply ink directly onto the corrugate. It's fast, efficient, and cost-effective for large runs with simpler graphics—think bold logos and text. Litho-lamination involves printing your photo-realistic artwork onto a thin sheet of paper first, which is then glued (laminated) onto the corrugate. The quality is exceptional, just like a magazine, but it's a multi-step process that costs more.

I worked with a snack brand that wanted a full-color, photographic image covering their entire pallet display. The litho-lamination cost was 40% higher than a simpler flexo design. For their premium brand identity and launch at Target, it was the right investment. Conversely, a CPG client selling value-packs at Sam's Club achieved fantastic results with a two-color flexo print that clearly stated the price and product benefit. It was bold, visible, and highly cost-effective.

Flexo vs. Litho: A Cost-Benefit Analysis

| Feature | Flexographic Printing (Flexo) | Lithographic Lamination (Litho) |

|---|---|---|

| Process | Ink applied directly to corrugate. | High-quality print laminated onto corrugate. |

| Best For | Simple graphics, logos, text, 1-4 solid colors. | Photographic images, complex gradients, premium branding. |

| Unit Cost | Lower. | Higher. |

| Setup Cost | Lower (cheaper print plates). | Higher (expensive metal plates and setup). |

| Retailer Fit | Excellent for club stores, discount chains. | Preferred by upscale grocers, Target, department stores. |

Beyond the method, factors like ink coverage (a full flood of color costs more than minimal text) and finishes like a UV coating for gloss and protection also add to the cost. The goal is to align your print choice with your brand, your budget, and the retailer's expectations.

Are Logistics and Store Labor the Hidden Drivers of Your Display Costs?

Your "cheap" flat-packed display requires 30 minutes of store labor to assemble. Retailers hate this inefficiency and may refuse to execute your program, leaving your displays in the back room.

Yes, logistics and store execution are huge hidden POP display cost drivers. A display that is difficult to ship, pack with product, or assemble in-store can cost more in labor, damages, and non-compliance fines than the unit itself.

Dive Deeper: Thinking Beyond the Factory Door

The cost of a display program doesn't end when it leaves my factory. In fact, some of the biggest expenses occur after that. This is where thinking about the total landed cost6 becomes critical.

A major decision point is choosing between flat-packed displays or pre-assembled/kitted displays. A flat-packed display ships efficiently, taking up minimal space in a container and truck. This saves on freight. However, the cost is transferred to the brand's co-packer or, even worse, to the retail store employee who has to build it. Store labor is expensive and inconsistent. Retailers want displays they can roll out and stock in minutes, not half-hour construction projects.

Real-World Scenario: The Power of Pallet Optimization

I had a client with a PDQ tray design for Walmart. Their original design allowed them to fit 200 trays in a shipping carton. By making a tiny structural change—less than half an inch—we were able to reorient the trays to fit 240 per carton. This single change meant we could fit 20% more units into every 40-foot shipping container from our port in China to their distribution center in the U.S. For a program of 10,000 displays, this small engineering tweak saved them over $8,000 in ocean freight alone.

We apply this thinking to everything:

- Pack-Out Efficiency: How quickly can a co-packer fill your display with product? We design for easy access and simple steps.

- Palletization: How many fully-loaded displays can fit on a truck to the retailer's DC? We design to maximize the pallet footprint without overhang.

- Store Setup: Can a single store employee get your display ready for shoppers in under 5 minutes? We aim for designs that are intuitive and require minimal steps.

Reducing time and friction at every step of the logistics chain is one of the most effective ways to lower your total retail packaging and display costs.

Why is Prototyping Essential for Controlling Retail Display Costs?

You skipped the prototype phase to save time and a few hundred dollars. The final production run had a fatal flaw, costing you the entire order and jeopardizing your retail launch.

Prototyping is a crucial cost-control measure. It allows you to physically test the structure, product fit, and assembly before committing to expensive tooling and a full production run. Catching a flaw at the prototype stage costs hundreds; catching it in production costs thousands.

Dive Deeper: The True ROI of a Physical Sample

I cannot stress this enough: a prototype is not an optional expense; it is the single best insurance policy for your entire display program. A 3D computer rendering can't tell you if your product will snag on a die-cut edge during pack-out. It can't prove the display will withstand a cross-country truck journey. Only a physical, production-grade prototype can do that.

The process is straightforward but invaluable. We take the approved structural design2 and create a full-scale, unprinted version using the exact board grade specified for production. We then ship this to you. You can then:

- Test the Assembly: Does it go together as easily as planned?

- Test the Product Fit: Does your product load correctly? Is it stable? Is it presented well to the shopper?

- Simulate Shipping: You can pack it, shake it, and see how it holds up.

- Gain Retailer Approval: Many retailers, especially for large programs, require a physical sample for review before they will approve a display for their stores.

A few years ago, a new client came to us after a disaster. They had a production run of 5,000 displays made elsewhere without a proper prototype. When their product arrived for pack-out, they discovered the internal cells were 1/4 inch too small. The entire run was useless. The loss was over $30,000. A single $400 prototype would have identified that error instantly. Prototyping de-risks the entire project and ensures that what you approve is exactly what you get in the final run.

Conclusion

To lower total display costs, focus on compliant engineering and logistics, not just unit price. Let's review your next design to find hidden savings and ensure retailer approval from day one.

Understanding these drivers can help you optimize your packaging strategy and reduce costs. ↩

Explore how effective structural design can save you money and improve display performance. ↩

Learn how the right material choice can prevent costly failures and enhance display durability. ↩

Discover how print choices can impact your budget and brand perception in retail. ↩

Learn how compliance can impact your display's success and cost-effectiveness. ↩

Gain insights into how total landed cost affects your overall display budget. ↩

Understanding the retail environment is key to creating effective and compliant displays. ↩

Understanding the importance of internal supports can enhance display stability. ↩

Meeting these demands is crucial for successful retail partnerships and compliance. ↩

Explore how the right board grade can enhance display strength and reduce costs. ↩

Learn how to balance cost and strength in your material selection. ↩

Discover how flexo printing can be a cost-effective solution for your display needs. ↩

Explore the importance of visual appeal in attracting customers and driving sales. ↩