Custom Corrugated Hangsell Display

A Custom Corrugated Hangsell Display is a retail display unit made from durable, lightweight corrugated cardboard, designed specifically to hang products in a way that maximizes visibility and accessibility for customers.

These displays are often used in high-traffic areas like checkout counters, end caps, or aisles to attract attention and encourage impulse buys.

Table of Contents (Guide to Custom Corrugated Hangsell Display)

General Applications For Corrugated Hangsell Display

What sets custom corrugated hangsell displays apart is their personalization. They can be fully customized to suit your specific needs, including size, shape, color, graphics, and branding.

This means you can create a display that not only holds your products securely but also reflects your brand identity and aligns with your marketing strategy.

Types of POS Corrugated Hangsell Display

Cardboard trolley expo boxes are quite simply categorised into 2 types based on their handle, one is corrugate material which can be done as a one-piece with the box main body, another is with a seperate plastic handle. Box sizes vary based on individual requirement.

Small Hangsell Units

- Customized

- No extra plastic handle

- Easy to fold and assemble

Sunglasses are impulse buys, and a well-designed display draws customers in, increasing the likelihood of spontaneous purchases.

A custom hangsell display is an excellent way to reinforce your brand’s identity and stand out in a competitive market.

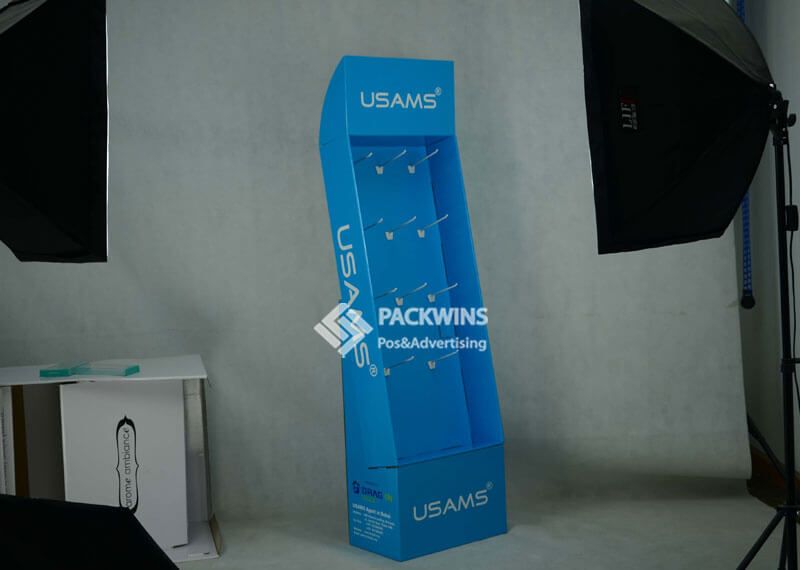

FreeStanding Hangsell Displays

- Customized

- Corrugated Recycled Cardboard

- Lightweight Glossy Laminated Material

A Free-Standing Hangsell Display is a versatile and eye-catching solution for showcasing products in any retail setting. Designed to stand independently on the floor, these displays offer maximum visibility, allowing your products to attract attention from every angle. With customizable designs and configurations, they can be tailored to fit your brand and display needs

Hangsell Sidekick Displays

- Customized

- Corrugated Recycled Cardboard

- Lightweight Glossy Laminated Material

Hangsell Sidekick Displays are compact, flexible units designed to complement your main product displays. Positioned alongside checkout counters, aisles, or end caps, these displays provide an additional space to showcase smaller items or impulse buys.

Wanna a complete range?

Estimated Cost Analysis For Corrugated Hangsell Display

Cost of a POS pallet display at manufacturer end can be break down into raw material and production cost. While at buyer’s ends, there are also shipping cost and tax factors to consider at landed cost. Kitting cost are something inbetween depends on where the displays are assembled.

Paper material cost - $800/T

Paper raw material price fluctuates from around $500/T in 2008 to $1200/T last year in 2021. For each display, the cost of paper depends mainly on the area of paper used. We design to maximize weight bearing capacity while minimize the amount paper used.

Printing cost - $0.3-1.5/print

Printing is very much a fixed cost. Assuming one KBA printing machine runs 24 hours a day with very stable running speed and skilled workman, the everage cost varies depend on sheet size from $0.3-1.5 per print.

Paper mounting and diecutting cost- $0.02-0.25/sheet

Besides the paper mounting and diecutting unit cost for each paper sheet, there will be a tooling cost for each cutting table at $25. Shared tooling cost lower down when quantity increases. This is the reason why most manufacturers welcome large qty.

Packing cost- $0-$2.5

There are 2 main types of packing for a corrugate pallet display depending on where and how the displays be assembled. Economic at manufacturer end is KDF (knock down off) flat packed onto pallets, or full assembled&consolidate with products.

Freight and shipping cost - $0.1-$3.5

Shipiping cost is the most uncontrollalble factor since COVID-19 broke out in 2020. Other than that we have find practical solutions to save shipping space and cut cost down. This need to be discussed case by case. Current average shipping cost would be $0.1-$3.5 2023.

The Process Flow & Duration Estimation

Here at Packwins we strive to minimize steps for a complete customized corrugate display order. From startup sketch design through prototyping, production and shipping. Each step shall be carried out under guidelines inhouse or brands&club stores’ standards.

Step 1: Idea Generate (1-2 days)

If you have or need a concept, we can assist you in making it a reality. We will walk you through and nail down the crucial variables to facilitate structural design by interacting with our experienced designer.

Step 2: Prototyping (1-2 days)

If you’re okay with the design, we’ll create a tangible sample. Before proceeding into large production, feel the sample with your hands. Particularly for a new client or project. This step helps save time and avoid issues at the first stage.

Step 3: Get Raw Material (1-3 days)

Once display structure and printing artwork been aproved by customer after reviewing sample, we shall issue PI for downpayment and start to prepare raw materials. Rolls for printing and corrugate core plate should be cut into size before production.

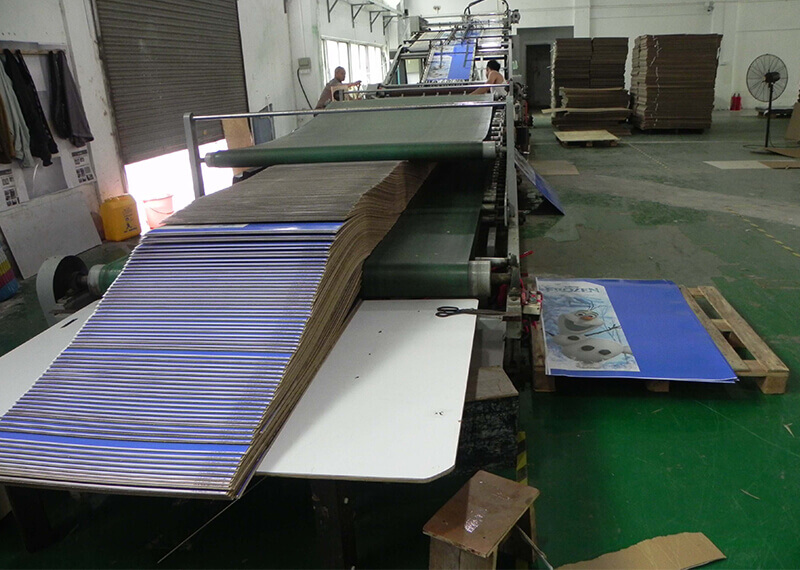

Step 4: Bulk Manufacturing (7-15 days)

As everything been nailed down and materials getting prepared, we start production from printing. Each sheet shall go through surface treating, paper mounting, diecutting, pasting and packing. Photos or videos shall be taken for customers to let you sleep at ease.

Step 5: Shipping (12-28 days)

Bookings be made in advance of the completion of the production. Air freight and maritime freight have different transit times. We’ll go over each case individually.

Want to know how to compress lead times?

In case you have an urgent order that need to be fulfilled less than our regular lead time, let’s discuss it here. There are alternative printing methods to offset, ie digital print direct to corrugate, and cut by laser cutting machine. Any thing is possible here.

Display Design Struggling? Here are the Keys.

Are you facing challenges with your retail displays? Whether it’s ensuring stability, customizing to fit your brand, or simplifying assembly, the right display can make all the difference.

In this guide, we break down the most common display design pain points and show you how our corrugated hangsell displays provide the perfect solution. Keep reading to unlock the keys to smarter, more efficient displays that drive sales and save you time.

Will It Hold Heavy Products?

The Problem: You need a display that can handle heavy products without breaking or becoming unstable.

Packwins’ Solution:

Our corrugate hangsell displays are built with multi-layered, reinforced cardboard to provide superior strength and durability. No matter how heavy your products are, they’ll be safely supported, even in high-traffic areas.

Customization Is Too Complicated?

The Problem: You want a display that represents your brand perfectly, but customizing it seems like a headache.

Packwins’ Solution:

Customizing your display is easy with our user-friendly process. Choose from a range of sizes, colors, and prints to create a display that fits your vision—and your budget. We’ll work with you to bring your ideas to life.

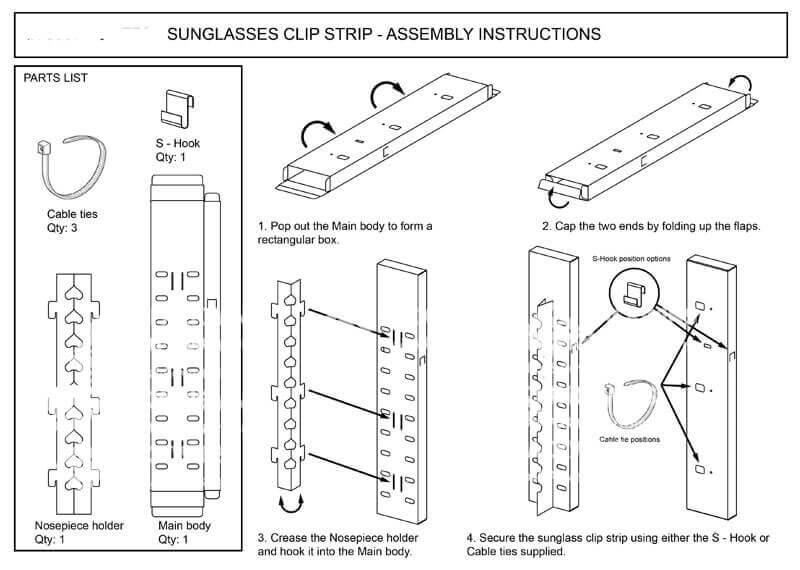

Assembly Takes Too Long?

The Problem: Assembly can be time-consuming, delaying your retail setups.

Packwins’ Solution:

Forget the hassle. Our displays are designed for quick, tool-free assembly. Clear instructions make setup a breeze—so you can focus on what matters: your products.

Environmental Impact Matters

The Problem: You’re looking for an eco-friendly solution, but cardboard displays are often seen as unsustainable.

Packwins’ Solution:

We care about the planet. That’s why our displays are made from 100% recyclable materials, and we use eco-friendly inks. Choose a display that meets your sustainability goals without compromising on quality.

Logistics Are Too Costly?

The Problem: Shipping large displays can be expensive, and storage takes up too much space.

Packwins’ Solution:

We’ve designed our hangsell displays to be flat-packed, reducing storage space and lowering shipping costs. Transport your displays efficiently without the added expenses.

The Hidden Challenges of Importing from China (And How to Overcome Them)

Importing from China can offer significant benefits—cost-effective manufacturing, a vast range of product options, and scalable production.

However, it also comes with a set of challenges that can catch businesses off guard. In this section, we will address the hidden pain points many companies face when importing from China and offer practical solutions to overcome them.

- Quality Control and Standards Compliance

- Unclear Procurement and Shipping Process

- Import Duties and Hidden Fees The Challenge

- Risk of Damaged Goods During Shipping

- Delays in Lead Times

Quality Control and Standards Compliance

Product Samples: Before full-scale production begins, we offer product samples to ensure the quality matches your expectations.

Unclear Procurement and Shipping Processes

Advanced Tracking: We offer full transparency on the shipment’s status, with tracking numbers, shipping times, and potential delays, so you’re never left in the dark.

Import Duties and Hidden Fees

Import taxes, tariffs, and additional fees (such as customs duties) can add up quickly, making the final cost much higher than anticipated. Without understanding the full breakdown of import expenses, businesses often face unexpected financial burdens.

Upfront Cost Transparency: We provide an accurate, upfront estimate of all import-related costs, including customs duties and taxes, so you can budget effectively.

Risk of Damaged Goods During Shipping

Damage Prevention Protocol: We follow strict packaging guidelines and conduct thorough inspections to ensure each item is securely packaged for transport.

Delays in Lead Times

Buffer Time in Scheduling: We always account for extra lead time in our scheduling to mitigate the risk of delays.

Fast Production Turnaround: With our streamlined production processes and reliable logistics partners, we ensure that your orders are produced and shipped as quickly as possible without compromising on quality.

Real-Time Communication: If any delays arise, we communicate proactively and provide alternative solutions, keeping you informed at every step.

A Brief Self-Nomination, Why Choose Packwins?

Packwins is a structrual design, manufacturing and trading combo in point of purchase display industry. The key to our success in the early stage is design. Nearly every manufacturer can do with a box, but only a few can create a display with robust structure.

Packwins understands the paper industry from a sustainable development view. We respect the nature and environment and have a deep knowledge on paper material costing. This helps us keep our clients’ cost down.

- Consultative, understanding retail.

- Creative, award-winning structural design

- Great action, reliable in printing, manufacturing.

- Care for customers opinion, quick answer to client’s request.

We like to be involved in the early design stage of a pos pallet display. This way we both on the same line and gets 100% guarantee that what we’ve done meets up all your expectation.

The FAQs About POS Cardboard Hangsell Display

Customers are free to ask questions online, via email, since you are always be back up by a professional team at Packwins. Here below are some of the frequently asked questions to clear out your concerns and doubts.

- Have no idea?

Simply give us spec of your product. We can create packaging and display for you from scratch. You can review by digital designed prototype, and touch by hands with physical samples. - Have an idea?

That’s great! Our design team shall bring your idea into reality. Most often we need to improve the strctural design from clients to ensure its functionality and asthetics.

Yes.

Packwins has quite sophisticated workers doing printing, diecutting, pasting and packing for pallet displays. Strcture design is done in-house. Graphic design can also be provided upon request.

Euro (ISO O) Standard Pallet Sizes (cm)

- Full pallet: 80 by 120

- 1/2 half pallet: 80 by 60

- 1/4 quarter pallet: 60/40

American Standard Pallet Sizes (inch)

- 45-48″W x 40”D

- 48”W x 20”D

- 24”W x 20”D

Yes.

And we welcome you to consult at any stage of your display development. From early stage we shall created display rendering with different options for you to choose from. Strcture design shall be based on your product and product packaging features.

- 1-3 days

Qty<10pcs - 9-12 days

Qty<1000pcs - 15-20 days

Qty>1000pcs

No.

- Digital printing there is no tooling, so that no tooling charge at all. We print direct to corrugate for a fast turnaround time 1-2 days.

- Offset printing there should be tooling or diecutting mold, but we won’t add extra cost in quote, since this tooling helps bring average cost down.

- The best and safest to pay is via Telegraphic Transfer.

- Alternatively we accept paypal, westunion, credit card.

Yes.

Packing method shall be taking into consideration during the early structure design stage to save shipping pace and cost.

We can find competitive shipping rates and advice in the quote if you don’t have a shipping agent, or simply you would like to compare rates.