Are you struggling to get your product noticed by major retailers? The path to big-box shelves1 is littered with brands that had a great product but failed on execution.

Getting into big-name retailers like Walmart or Target requires more than a great idea; it demands flawless execution2. Success hinges on preparing your product, packaging, and supply chain3 for the rigorous operational standards of mass retail, a step many brands unfortunately overlook until it's too late.

Getting onto the shelves of a major retailer is a goal for so many brands I work with. But I’ve seen many pitches fail not because the product was bad, but because the brand wasn't truly "retail-ready." Big-box stores are systems built for efficiency. A product that doesn't seamlessly fit into their logistics4 is a non-starter. Preparing correctly from the start makes all the difference, transforming your pitch from a hopeful request into a credible business proposal. Let's walk through the essential steps to get your product ready for the big leagues.

Do You Understand What Big Retailers Really Want?

Feeling like retail buyers are speaking a different language? You have a fantastic product, but the conversations stall around logistics4 like case-packs and shelf footprints, leaving you confused.

Retail buyers evaluate products on operational efficiency5, not just quality. They care about how easily your product can be received, stocked, and sold. Overlooking their packaging, labeling, and display requirements is a fast track to rejection before your product's merits are even considered.

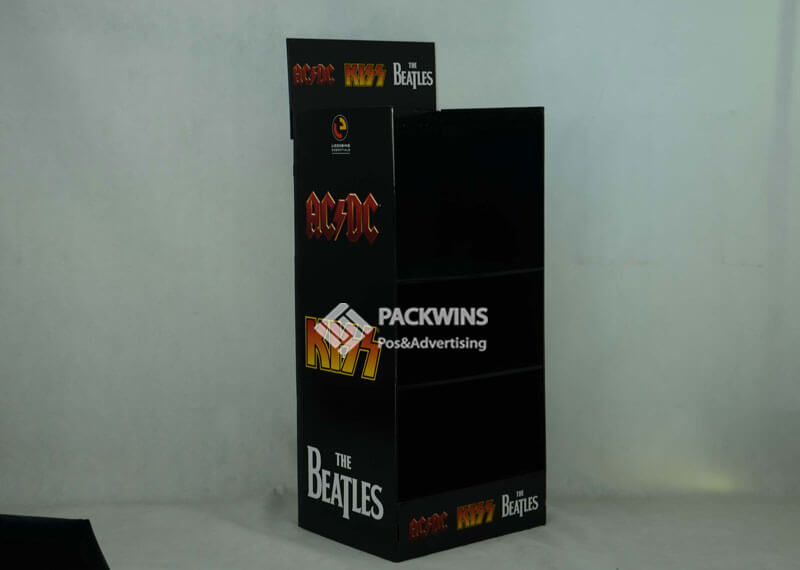

Big retailers aren't just buying your product; they are buying into your entire operational process. They expect you to understand their world, which is built on speed and volume. A common mistake I see is brands focusing 100% on product features while completely ignoring how it will perform in a retail environment. Buyers need to know your product will arrive in compliant packaging, fit their specific shelf dimensions, and be easy for store employees to handle. This is where we, as partners at Packwins, often step in. We help brands translate their product into a retail-ready format. We ensure the packaging specifications6 are perfect and that any point-of-purchase (POP) displays7 are pre-approved and compatible with store layouts. Thinking about these details early shows a buyer you’re a serious partner who understands their business, not just another hopeful with a good idea.

Is Your Packaging Genuinely Retail-Ready for Shelves and Displays?

Is your current packaging designed for e-commerce or small shops? You might be realizing that what works online won't survive the journey to a big-box shelf or attract customers there.

Your packaging must be durable, easy for staff to handle, and visually compelling on a crowded shelf. It must also integrate with in-store displays. Packaging that requires complex handling or doesn't fit standardized shelving is a significant operational burden for retailers.

Retail-ready packaging, often called shelf-ready packaging (SRP)8, is a non-negotiable for most major retailers. Their goal is to get products from the truck to the shelf in the shortest time possible, and SRP is designed to make that happen. Brands often fail here by providing packaging that needs to be unboxed item by item, a huge time-waster for store associates. Another error is designing packaging that looks great up close but becomes invisible on a long aisle. Your packaging must work hard at every step. It needs to protect the product through a complex supply chain3, be simple for an employee to open and place on the shelf, and grab a shopper's attention. At Packwins, we engineer packaging and POP displays that meet these demands, ensuring everything is optimized for visibility, durability, and stocking efficiency.

Retail-Ready Packaging Checklist

| Requirement | Why Retailers Care | Packaging / Display Solution |

|---|---|---|

| Easy to Identify | Warehouse staff need to find your product quickly. | Clear branding and barcodes on multiple sides of the master carton. |

| Easy to Open | Reduces stocking time and prevents injuries from box cutters. | Perforated trays and tear-strips that require no tools. |

| Easy to Stock | Allows for rapid replenishment of shelves with minimal disruption. | Trays that slide directly onto shelves as a single unit. |

| Easy to Shop | Ensures customers can easily see and take the product. | Low-profile tray fronts that don’t hide the product. |

| Easy to Dispose | Simplifies cleanup for store staff and meets sustainability goals. | 100% recyclable materials and minimal components. |

Can You Prove Your Product Sells Itself Off the Shelf?

Worried that you don't have enough sales data to impress a big-box buyer? You believe in your product, but proving its potential to sell in a high-volume environment feels impossible.

Retail buyers are risk-averse; they need proof of demand. Your packaging is a key part of this proof. It acts as your silent salesperson on the shelf, and its ability to attract and convert shoppers is a critical indicator of your product's potential success.

Your packaging is your most important marketing tool in a retail store. Buyers know that a product's success often comes down to whether its packaging can capture a shopper's attention in three seconds or less. A common mistake brands make is assuming a great product will sell itself. In a sea of competitors, it won't. Your packaging must clearly communicate what your product is and why a customer should buy it. I’ve seen brands dramatically increase their sales velocity9 simply by redesigning their packaging for better shelf impact. This is where a strong design partner like Packwins can be invaluable. We help create packaging that not only looks good but is strategically designed to drive trial and impulse purchases. By showing a buyer a "before and after" of your packaging and how a POP display can create brand blocking, you're not just showing them a product; you're showing them a sales strategy.

Are Your Margins and Supply Chain Ready for a Retail Deal?

Does the thought of calculating retailer margins10 and factoring in all costs feel overwhelming? Many brands underestimate the true cost of getting a product onto a retail shelf, jeopardizing their profitability.

Big retailers operate on thin margins and expect you to have a firm grasp of your numbers. Underestimating costs related to packaging, displays, and logistics4 can erase your profit and make a retail partnership unsustainable before it even begins.

Getting your pricing right is one of the most critical steps, and it’s where I see many brands stumble. They calculate their product cost but forget to account for the significant expenses of retail-ready packaging, POP displays, freight, and potential chargebacks. Retail buyers will drill down into your numbers, and if they sense you haven't done your homework, you lose all credibility. Forgetting to factor in the cost of a corrugated POP display or the switch to more durable shipping cartons can be a fatal error. These aren't minor expenses; they are central to your cost of goods sold in a retail channel. At Packwins, we work with brands early in the process to engineer packaging and display solutions that fit within their target cost structure. We explore different materials and designs to find the right balance, ensuring you can meet retailer requirements without sacrificing your margin.

Packaging & Display Cost Impact

| Element | Cost Impact | Retail Risk if Ignored |

|---|---|---|

| Primary Packaging Materials | High (10-40% of retail price). | Premium materials can price you out of a category. Low-quality materials can lead to damage. |

| Corrugated POP Displays | Moderate to High (Unit cost decreases with volume). | Buyers may reject a pitch without a display strategy. Underbudgeting hurts your margin. |

| Master Cartons / Shippers | Moderate | Weak shippers lead to damaged products and retailer fines. Non-compliant sizes cause logistical issues. |

| Labor & Assembly | Low to Moderate | Complex packaging or displays increase labor costs for you or the retailer, reducing overall profitability. |

Is Your Product Fully Compliant and Documented for Retailers?

Are you prepared for the mountain of paperwork and compliance checks that come with a retail partnership? Overlooking safety standards, insurance, or labeling rules can bring your onboarding process to a screeching halt.

Big retailers have strict compliance protocols11 to protect themselves and their customers. Failing to provide the correct documentation for product safety, insurance, and packaging standards will result in immediate delays or disqualification from their program.

Compliance is not the most exciting part of this process, but it's one of the most important. Retailers like Walmart and Target have extensive supplier guides that detail everything from barcode placement to the types of materials allowed in packaging. A frequent mistake is assuming your current setup is "good enough." It rarely is. For example, some retailers have specific requirements about recycled content in corrugated displays or forbid certain types of plastic. You will also need to provide proof of product liability insurance12, often for significant amounts. These are not suggestions; they are hard requirements. Making the wrong material choice in your packaging design can force you into a costly redesign late in the game. We guide our clients at Packwins through these technical specifications, ensuring that the structural design13 and materials we propose will pass retail audits and keep the onboarding process moving smoothly.

Does Your Pitch Show Retail Buyers Exactly What They Need to See?

Do you plan on just talking about your product in your buyer meeting? A pitch without visual aids or physical samples often fails to make a memorable impact, leaving buyers questioning your readiness.

Buyers are visual people who manage physical spaces. They need to see how your product will look on their shelves and how a display will command attention in their stores. Providing mockups14 shows you've thought through the execution and helps them envision your product's success.

When you walk into a buyer meeting, you need more than a slideshow. You need to bring your product to life. I've seen buyers' eyes light up when a brand unveils a physical mockup of their packaging or a scaled-down model of a POP display. It instantly answers so many of their questions. A common mistake is to only show a digital render. While helpful, a physical sample allows them to feel the material quality and see the true colors and scale. It builds confidence. Bringing a prototype of a POP display demonstrates that you're thinking about scale and how you can help them drive volume. As a partner, Packwins frequently creates these essential sales tools for our clients. From high-fidelity packaging mockups14 to fully functional display prototypes, we provide the physical proof that helps you tell a more compelling story and shows the buyer you are prepared to execute.

Can You Reliably Distribute and Replenish at Scale?

Have you thought about what happens after you get a "yes"? The excitement of landing a deal can quickly turn to panic if you can't produce and ship your product reliably at scale.

A "yes" from a retailer is the starting line, not the finish line. You must have a solid plan for production, distribution, and replenishment. Any failure to deliver on time and in full can damage your relationship and lead to being delisted.

The real test begins after you get the purchase order. The retailer expects you to transition from pitch mode to execution mode flawlessly. A massive mistake brands make is having their packaging and display designs finalized but no plan for mass production. Your small-batch supplier might not be able to handle an order for 1,000 stores. The design that was easy to assemble by hand for a prototype might be a logistical nightmare for a co-packer. This is why it’s crucial to design for scale from the very beginning. At Packwins, our engineering process always considers high-volume production. We design packaging that runs efficiently on automated assembly lines15 and POP displays that ship flat and are easy to set up in-store. Thinking about these production realities early on prevents costly and time-consuming redesigns after you've already won the business, ensuring you can scale smoothly and successfully.

Packaging & Display Scale Readiness

| Area | Small Batch Risk | Retail Scale Requirement |

|---|---|---|

| Material Sourcing | Using unique, hard-to-find materials. | Consistent, reliable supply of materials that are available in large quantities. |

| Structural Design | Overly complex designs that require manual assembly. | Designs optimized for automated die-cutting, folding, and gluing to reduce labor costs. |

| Printing | Digital printing, which is slower and more expensive per unit. | Offset or flexographic printing for high-volume runs to achieve lower per-unit costs. |

| Logistics | Shipping fully assembled units. | Designs that ship flat to maximize pallet space and reduce freight costs. |

Conclusion

Getting into big-name retailers is about proving you can execute, not just pitching an idea. Your packaging and displays are critical approval tools, not afterthoughts. Brands that prepare these elements early win faster.

Understanding the challenges of big-box shelves can help you navigate the complexities of retail distribution. ↩

Learn why flawless execution is crucial for transforming a great product into a retail success story. ↩

Understand the role of a robust supply chain in securing and maintaining retail partnerships. ↩

Learn about the critical role of logistics in ensuring successful and sustainable retail partnerships. ↩

Explore how operational efficiency impacts a product's acceptance by major retailers. ↩

Ensure your packaging meets the necessary specifications to avoid rejection by retail buyers. ↩

Find out how effective POP displays can enhance product visibility and drive sales in retail environments. ↩

Learn about the importance of shelf-ready packaging in streamlining the stocking process for retailers. ↩

Discover how a strategic packaging redesign can significantly boost your product's sales velocity. ↩

Learn how understanding retailer margins is essential for setting competitive and profitable product prices. ↩

Ensure your product meets all compliance protocols to avoid delays or disqualification from retail programs. ↩

Understand the necessity of product liability insurance in protecting both retailers and suppliers. ↩

Understand how structural design impacts the efficiency and cost-effectiveness of retail packaging. ↩

See how using mockups in pitches can make a lasting impression on retail buyers and improve your chances of success. ↩

Learn how automated assembly lines can optimize packaging processes for large-scale retail distribution. ↩