Struggling to enter the U.S. market? Your packaging might be the problem. A misstep here can cost you sales and create logistical nightmares. We have the solutions.

Successfully preparing your product packaging for the U.S. market involves optimizing design for consumers, ensuring regulatory compliance1, using sustainable materials2, streamlining for shipping, ensuring durability3, maintaining consistent branding, optimizing size, and adapting to trends. These steps ensure market acceptance4 and efficiency.

Getting your product on U.S. shelves is a huge achievement. But the real work is making sure it sells. The packaging is your first and most important salesperson. Let's break down exactly how you can make your packaging work for you in this competitive market. We'll go through eight key areas to get you started.

How can you optimize packaging design5 to meet U.S. consumer and retailer expectations?

Is your packaging design5 failing to connect with U.S. shoppers? This disconnect can lead to poor sales. We help you bridge that gap with culturally relevant designs.

Optimize your design by focusing on aesthetics that appeal to U.S. tastes, such as clean lines and clear messaging. Ensure functionality with easy-to-open features. Also, align with retailer requirements for shelf space6 and display, like those at Walmart or Costco.

When we design for the U.S. market, we balance three key things: how it looks, how it works, and how it fits in the store. This is a crucial mix to get right. If you miss one part, the whole strategy can fall apart.

Understanding U.S. Aesthetics

U.S. consumers are busy. They often prefer packaging that is easy to understand. This usually means minimalist designs7 with clear, bold text. They want to know what the product is and why they should buy it in just a few seconds. While some product categories allow for busy, colorful graphics, clarity is almost always the winner. We focus on creating a design that communicates the product's main benefit instantly.

Functionality is Key

The "unboxing experience8" is a real marketing tool now. We think about how the customer will interact with the package. Is it easy to open? Can it be resealed? Are the instructions simple to find? Frustrating packaging can create a negative first impression of your product. We design with features like tear strips and resealable closures to make the customer's life easier.

Meeting Retailer Demands

Big retailers like Walmart and Target have very specific rules. We know this because we design point-of-purchase displays for them. They dictate shelf dimensions, barcode placement9, and how products must be packed in master cartons. If your packaging doesn't meet these requirements, they may not stock your product. We design with these rules in mind from day one.

| Feature | U.S. Consumer Preference | U.S. Retailer Requirement |

|---|---|---|

| Visuals | Clean, minimalist, clear | Easy to scan, fits shelf |

| Functionality | Easy-to-open, resealable | Durable, easy to stock |

| Information | Key benefits upfront | UPC barcode correctly placed |

How can you ensure packaging compliance with U.S. regulatory standards?

Worried about U.S. customs rejecting your shipment? Non-compliant packaging is a common reason. This can lead to costly delays, fines, and returned goods. Let's fix that.

Ensure compliance by following FDA regulations10 for food and drug products, accurately listing all ingredients, and using proper nutritional labels. Also, include necessary warnings and certifications. Always verify requirements with a legal expert to avoid penalties and ensure smooth market entry.

Navigating U.S. regulations can feel overwhelming. The rules are strict and vary by product type. We've seen many companies make small mistakes that lead to big problems at the border. Getting this right is not optional; it is essential for doing business in the United States.

Navigating FDA Rules

If your product is a food, beverage, cosmetic, or medical device, you have to follow rules from the Food and Drug Administration (FDA). These rules are very detailed. They cover the types of materials that can safely touch your product. They also dictate exactly what information must be on the label. We always tell our clients that this is the first hurdle to clear. If your packaging material isn't FDA-approved for your product type, you need to change it.

Accurate Labeling is Non-Negotiable

The information on your package must be 100% accurate and formatted correctly. For food, the Nutrition Facts panel has a specific layout that must be followed. Ingredients must be listed in descending order by weight. Any major allergens, like nuts or milk, must be clearly declared. We help our clients organize this information, but we always recommend a final review by a U.S. compliance specialist. A simple mistake here can trigger a full product recall.

Important Certifications

Beyond government rules, certain certifications can be very important. For example, if you claim your product is "organic," you must have the official USDA Organic seal. If you use paper packaging, retailers like to see the Forest Stewardship Council (FSC) logo. These certifications build trust with both consumers and retailers.

| Regulation Area | Key Requirement | Who it Applies To |

|---|---|---|

| FDA Regulations | Food-safe materials, proper labeling | Food, drugs, cosmetics, medical devices |

| Fair Packaging & Labeling Act | Product identity, net quantity, manufacturer name/address | Most consumer products |

| State-Specific Laws | E.g., California's Proposition 65 warning labels | Products sold in specific states |

How can you leverage sustainable packaging to appeal to U.S. consumers?

Are U.S. buyers ignoring your product? They might see your packaging as wasteful. This perception can damage your brand image. Sustainable packaging can change that story.

Appeal to U.S. consumers by using recyclable, biodegradable, or compostable materials. Clearly communicate your sustainability efforts on the packaging itself. This meets growing consumer demand for eco-friendly products11 and can improve your brand's reputation with both shoppers and importers.

Sustainability is not just a trend in the U.S.; it's becoming a core expectation for many consumers. They are actively looking for brands that align with their values. We've found that highlighting your eco-friendly practices can be a powerful way to connect with these shoppers.

Choosing the Right Materials

The first step is selecting materials that are better for the environment. Corrugated cardboard, our specialty, is a great choice because it's made from a renewable resource and is widely recycled in the U.S. We help our clients choose the right type of cardboard and minimize its use. Other options include materials that are compostable or made from recycled content. The key is to choose a material that still protects your product effectively while also meeting your sustainability goals.

Communicating Your Green Efforts

Using sustainable materials2 is great, but you have to tell your customers about it. They won't know unless you make it clear. We often incorporate simple logos, like the standard recycling symbol, or short phrases like "Made from 80% Recycled Materials" directly into the packaging design5. This small detail can make a big difference in a consumer's purchasing decision. It shows that your brand is thoughtful and responsible.

The Business Case for Sustainability

This isn't just about feeling good. It's good for business. Many large U.S. retailers have their own sustainability goals. They often prefer to partner with brands that can help them meet those targets. Being a leader in sustainable packaging can open doors with major buyers and importers. It can become a key part of your brand identity and a real competitive advantage.

| Material Type | Key Benefit | Best For |

|---|---|---|

| Recycled Cardboard | Reduces waste, widely recyclable | Shipping boxes, product packaging, displays |

| Compostable Plastics | Breaks down in industrial facilities | Food packaging, single-use items |

| FSC-Certified Paper | Sourced from responsible forests | Labels, premium product boxes |

How can you streamline packaging to reduce shipping costs12?

Are high shipping costs12 eating into your profits? Bulky, inefficient packaging is often the culprit. This waste adds up quickly. We can help you optimize it.

Reduce shipping costs12 by minimizing packaging size and weight. Use lightweight but strong materials like corrugated cardboard. Eliminate empty space inside the box with custom inserts13. This lowers dimensional weight charges and improves overall logistics efficiency from China to the U.S.

Shipping products across the ocean is expensive. Every dollar counts. We've learned that one of the easiest ways to save money is by making the packaging as efficient as possible. Small changes to a box design can lead to huge savings on a full container load.

The Impact of Dimensional Weight

International carriers like DHL, FedEx, and UPS use a pricing model called dimensional weight, or DIM weight. They charge you based on the size of the box, not just its actual weight. This means a large, lightweight box can be surprisingly expensive to ship. Our first goal is always "right-sizing" the package. We design a box that fits your product with very little extra space. This directly lowers the billable weight of every shipment.

Choosing Lightweight, Strong Materials

The next step is to reduce the actual weight. We specialize in corrugated cardboard, which offers an excellent strength-to-weight ratio. We can help you select the right grade of cardboard that protects your product without adding unnecessary grams. Modern engineering means we can often use thinner, lighter board than you might expect, while still maintaining structural integrity. This saves money on materials and on shipping.

Eliminating Wasted Space

Empty space inside a box is your enemy. It adds to the box's size, increasing DIM weight, and often requires extra filler materials like bubble wrap or packing peanuts. We design custom inserts13 from folded cardboard that hold your product securely in place. This eliminates the need for void-fill, reduces the overall package size, and often provides better protection. It's a smarter, cheaper, and more sustainable solution.

| Optimization Strategy | How It Saves Money | Our Approach |

|---|---|---|

| Right-Sizing the Box | Lowers dimensional (DIM) weight charges | Create a custom box that fits the product snugly |

| Lightweight Materials | Reduces the actual weight of the shipment | Select the lightest grade of cardboard that works |

| Custom Inserts | Eliminates empty space and costly void-fill | Design structural inserts to hold the product |

How do you design packaging for maximum durability3 and damage prevention?

Are your products arriving damaged in the U.S.? This leads to returns, unhappy customers, and lost revenue. Poor packaging is a major liability. Let's build a better solution.

Design durable packaging by using high-quality materials like multi-layered corrugated board. Use custom inserts13 to brace the product and prevent movement. Also, conduct transit tests14, like drop tests, to ensure the packaging can withstand the stresses of international shipping and handling.

A product's journey from a factory in China to a customer's home in the U.S. is a rough one. It will be loaded, unloaded, stacked, and sometimes dropped. Your packaging is the only thing protecting your investment. We treat protective design as a science.

The Right Material for the Job

It all starts with the material. For lightweight items, a simple single-wall corrugated box might be enough. But for heavy, bulky, or fragile products, we need something stronger. We often recommend double-wall or even triple-wall corrugated board. These materials have multiple layers of fluting, which provides incredible cushioning and resistance to crushing. We analyze your product's weight and fragility to select the perfect material grade.

The Importance of Structural Design

The box itself is just the outer shell. The magic happens inside. A great structural design holds the product in the center of the box, away from the walls. We create custom-engineered inserts, supports, and cushioning from folded cardboard. These pieces lock the product in place, so it can't shift around during transit. They also absorb shocks from impacts. This internal structure is just as important as the outer box.

Testing for Real-World Conditions

How do we know if a design is strong enough? We test it. We always create a physical prototype of our designs. We encourage our clients to perform real-world tests. This includes drop tests from various heights and angles to simulate being dropped by a handler. We also recommend vibration tests to simulate the long journey on a truck or ship. It's much cheaper to find a weak spot in one prototype than to discover it after a thousand units have been damaged.

| Protection Element | Purpose | Example |

|---|---|---|

| Outer Box Material | Resist crushing and punctures | Double-wall corrugated board for heavy items |

| Internal Inserts | Absorb shock and prevent movement | Custom-folded cardboard braces |

| Cushioning | Protect against drops and impacts | Air gaps designed into the structure |

How can you integrate branding consistently across all packaging?

Does your product get lost on a crowded U.S. shelf? Inconsistent branding can make your product look unprofessional. This confusion costs you brand recognition and sales.

Integrate branding by using your logo, brand colors, and typography consistently across all packaging elements. This includes the primary product box, the shipping carton, and in-store displays (PDQs). This cohesion builds brand recognition and trust with U.S. consumers.

Your packaging is a critical part of your brand identity. In the U.S., where shelves are crowded with choices, a strong and consistent brand look can make all the difference. It helps customers find you, remember you, and trust you.

Your Packaging is Your Brand Ambassador

Think of your favorite brands. You can probably picture their packaging in your mind. That's the power of great branding. The package is often the first and only "salesperson" a customer interacts with. It needs to communicate your brand's personality in an instant. Is your brand fun? Premium? All-natural? The colors, fonts, and images you choose should all work together to tell that story. We work closely with our clients to translate their brand guidelines into a physical package that makes a great impression.

Consistency Across All Touchpoints

Strong branding isn't just about the box the customer takes home. It's about every piece of packaging in the supply chain. We believe the shipping carton (master carton) should also be branded. The point-of-purchase display (like a PDQ or pallet display) in the store must absolutely feature your branding. When a retailer sees a pallet of consistently branded cartons, it looks professional. When a customer sees your product in a custom display, it stands out. This consistency builds a powerful, memorable brand image.

Standing Out on the Shelf

In a typical U.S. supermarket, a customer might see hundreds of products in a single aisle. Your packaging has to work hard to grab their attention. A consistent and well-defined brand look helps you cut through the noise. When a customer sees your distinct color or logo, it's a mental shortcut. They don't have to re-evaluate your brand every time. This recognition is key to building customer loyalty.

| Packaging Element | Branding Goal | Key Components |

|---|---|---|

| Primary Package | Attract the customer, communicate value | Logo, brand colors, key messaging |

| Shipping Carton | Professionalism, easy identification for logistics | Logo, product name, item number |

| Retail Display | Create a "store-within-a-store," drive sales | Bold graphics, brand story, call to action |

How can focusing on packaging size and shape lead to cost-effective solutions?

Are storage and shipping fees draining your budget? Oddly shaped or oversized boxes are inefficient. This wasted space costs you money at every step. Let's optimize it.

Optimize size and shape to maximize how many units fit on a pallet and in a shipping container. Custom-designed packaging that perfectly fits your product eliminates wasted space. This reduces shipping costs, lowers storage fees, and makes handling more efficient for retailers.

Efficiency is the name of the game in logistics. The size and shape of your packaging have a massive impact on your costs throughout the entire supply chain, from our factory in China to a warehouse in the U.S. We design packaging with this entire journey in mind.

Designing for the Pallet

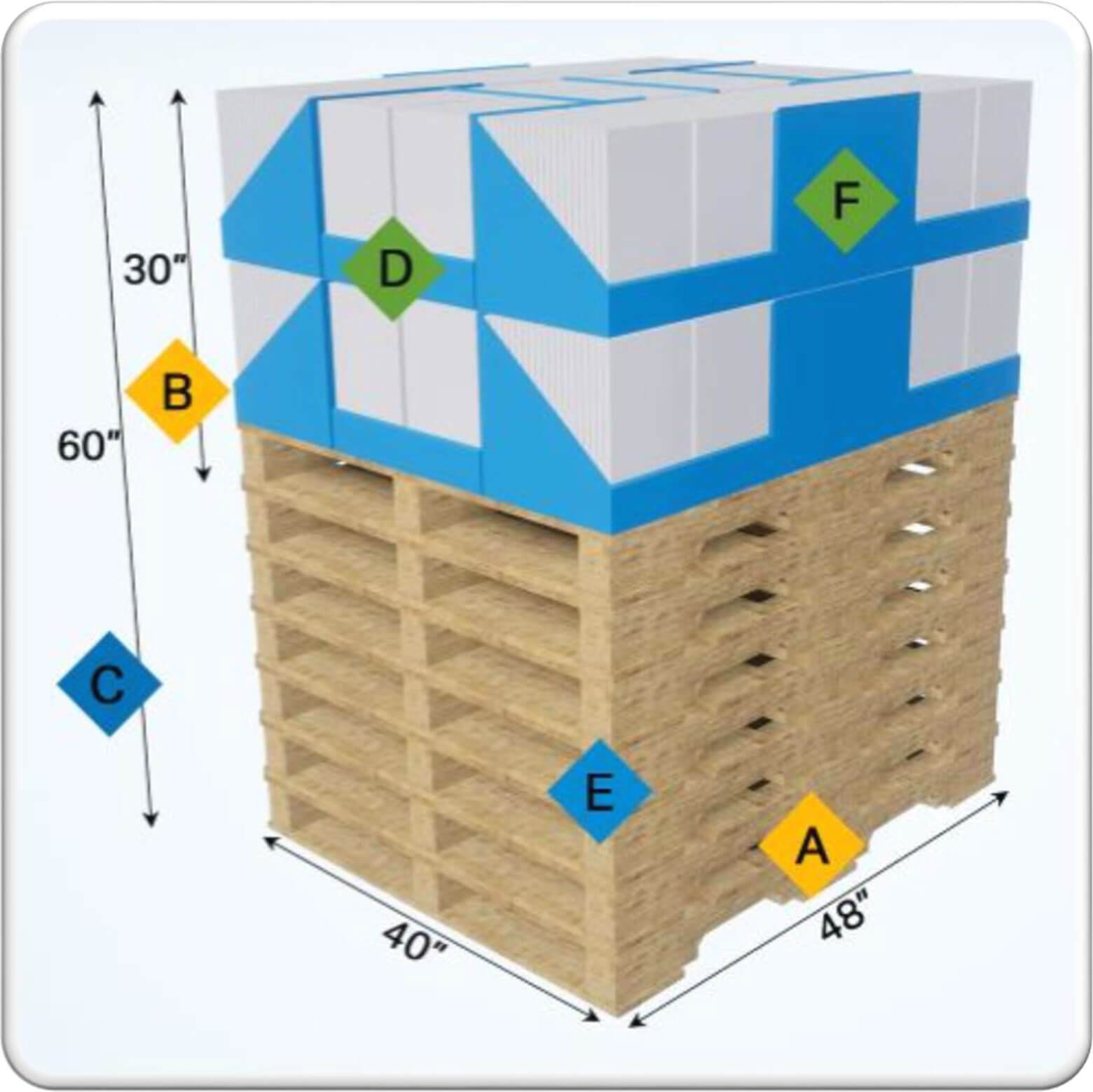

The standard shipping pallet is the basic unit of logistics. In the U.S., the most common size is 48 x 40 inches. We design our clients' boxes with these dimensions in mind. Our goal is to create a box size that allows for a perfect stacking pattern on the pallet, with no wasted space and no overhang. Getting more boxes onto a single pallet means you can fit more pallets into a shipping container. This directly translates to a lower shipping cost per unit, which is a huge competitive advantage.

Reducing Warehouse Footprint

Warehouse space in the U.S. is expensive. You are charged for the volume your products occupy. Inefficient packaging with a lot of empty space means you are paying to store air. By designing compact, right-sized packaging, we help our clients reduce their warehousing costs. Uniform, stackable boxes are also easier and faster for warehouse workers to handle, which can reduce labor costs and minimize damage.

The Power of Custom Shapes

For products with an awkward or unusual shape, using a standard rectangular box is extremely wasteful. We specialize in creating custom-engineered packaging that follows the contours of the product. This might mean a triangular box, a box with special cutouts, or a completely unique shape. While the box itself might be slightly more complex, the savings in shipping and storage costs are almost always worth it. It's a smart investment that pays for itself quickly.

| Factor | Standard Box Issue | Custom Box Solution |

|---|---|---|

| Shipping Cost | Wasted space leads to high DIM weight charges | Fits the product snugly, minimizing volume |

| Pallet Efficiency | Awkward stacking, fewer units per pallet | Designed to create a perfect, stable pallet cube |

| Product Protection | Product can shift inside, requires lots of filler | Custom inserts hold the product securely |

Why must you monitor and adapt to packaging trends in the U.S. market?

Does your packaging look dated next to competitors? Falling behind trends can make your brand seem irrelevant. This can quickly lead to a decline in sales.

Monitor trends to stay relevant and meet evolving U.S. consumer expectations. Current trends include minimalist design, smart packaging with QR codes for engagement, and innovative sustainable materials. Adapting to these trends keeps your brand competitive and appealing to modern shoppers.

The U.S. retail market is dynamic and changes quickly. The packaging that was successful five years ago might not work today. As your design and manufacturing partner, we believe it's our job to stay on top of these trends so we can give you the best advice.

The Rise of Minimalism

We see this trend across many categories. U.S. consumers are often overwhelmed by choice and information. A simple, clean, and honest packaging design can feel like a breath of fresh air. This means using fewer colors, simple fonts, and a lot of "white space." Minimalist design can communicate confidence and quality. It says that the product inside is so good, it doesn't need a flashy box. We help clients achieve this look while still including all the necessary information.

Interactive and Smart Packaging

Technology is creating new opportunities. We can now easily and cheaply integrate technology into our cardboard packaging. The most common example is the QR code. We can print a code on your box that a customer can scan with their phone. This code can link to a setup video, a recipe, a special discount, or your brand's social media page. This turns the package from a simple container into an interactive experience that builds a deeper connection with the customer.

Staying Ahead with New Materials

Innovation is constant. We are always researching new materials and techniques. This includes new coatings that can make cardboard more water-resistant, new inks that are more eco-friendly, and new types of paperboard made from alternative fibers like bamboo or sugarcane. By staying informed about these developments, we can help you be a leader in your category and offer your customers a packaging experience that feels new and exciting.

| Trend | Description | Why It's Important for the U.S. Market |

|---|---|---|

| Minimalism | Clean, simple designs with a focus on typography | Conveys honesty, quality, and stands out from clutter |

| Smart Packaging | Integrating QR codes or other tech for digital interaction | Engages customers beyond the point of sale |

| Innovative Materials | Using new, sustainable, or performance-enhanced materials | Shows your brand is forward-thinking and responsible |

Conclusion

Preparing packaging for the U.S. market requires a strategic approach. By focusing on design, compliance, and efficiency, you can ensure your product not only arrives safely but also succeeds.

Understanding compliance is crucial to avoid costly delays and ensure smooth market entry. ↩

Learn about eco-friendly materials that can enhance your brand image and appeal to conscious consumers. ↩

Find out how to create packaging that protects your products during transit and reduces returns. ↩

Discover strategies to design packaging that resonates with consumers and meets market demands. ↩

Explore innovative strategies to enhance your packaging design, ensuring it resonates with U.S. consumers. ↩

Discover tips for designing packaging that maximizes shelf space and attracts retailer interest. ↩

Understand the appeal of minimalist designs and how they can attract U.S. consumers. ↩

Explore ways to make the unboxing experience memorable, boosting customer satisfaction and loyalty. ↩

Ensure your packaging meets retailer requirements with proper barcode placement for easy scanning. ↩

Stay informed about FDA requirements to ensure your food products meet safety standards. ↩

Explore marketing strategies that highlight your commitment to sustainability and attract eco-conscious buyers. ↩

Discover effective strategies to minimize shipping expenses through optimized packaging solutions. ↩

Learn how custom inserts can enhance product protection and reduce shipping costs. ↩

Discover essential tests to ensure your packaging withstands the rigors of shipping. ↩