To get your P.O.P display project ready for commercial printing, we have a guide to walk you through. This guide will cover technical do’s and dont’s, and a step by step procedure to follow. You will find it super duper easy to carry out.

A Few Definitions.

Bleed

A bleed is the area between edge of printing paper and the dieline. Since there are other processes after printing, we need to leave sufficient areas to handle the sheet like in diecutting. And beside printing itself, there will need a safe zone to the edge to make sure every graphic elements are included in the printing work.

There might be subtle variations during the printing process, if we leave 1/8 inch space between cutting line and the paper edge, there won’t be any issue.

Why are bleeds important?

You don’t allow your artwork to be cut out and leave incomplete look. The bleed protects your graphics and elements from trimed.

There should be at leaset 1/8 bleed on all direction of your design.

How to Plan Your Bleed?

Simply create a bleed that is 0.125″ on all sides.

Color

CMYK not RGB

In your computer it uses a color space called RGB, printing press uses a color space of CMYK to produce colors. There are 4 ink colors when we doing offset printing, those are cyan, magenta, yellow and black. So in bulk order printing for cardboard display artwork files should be in CMYK color space, not RGB.

Full Color

In most of the case, our quote sheet would mention printing method be offset full color printing. That is to say we are using all four process colors. Your graphics and images shall be vivid to life under this printing process.

Spot Color

Most of the color produced in display printing are created by mixing just 4 colors of ink CMYK, but you might need a very specific color to represent your brand. Take for example, Coca-Cola’s trademark red, Walmart’s classical blue, you will need to use a spot color.

In case you need to use spot color, you could share us your PMS color number, PMS is short for Pantone Matching System. And there are 2 versions of PMS color, coated or uncoated. In cardboard display printing, we often apply coated version.

To exactly matching colors to your brand is challenging, and color match from order to order is even tricky, however when we have PMS, things become much simple. Color consistent is what seperates good printers from great ones.

We need to make a seperate plate for PMS color, which is why spot color printing will be more expenseive than full color. Good news is that it become more economical if you are doing larger quantities in today’s offset printing.

Resolution and Quality

Resolution is simply how many pixels per inch in an artowrk. The more the higher resolution it is.

Planning Image Quality for Professional Printing

Low resolution images might be defiend as low quality. It turns out to be very terrible, ugly printing.

How to aviod this bad result? You should plan at the beginning of your design, or you might be left with an unusable graphic design. Higher resolution higer quality.

Prints will always look greater with higher resolutions graphics. Image resolution is how many pixels are in the image, as we described above. When we print an image, we transfer the data into dots per inch(DPI). DPI determines the image quality. Usually 300DPI is what we need.

Vector Artwork

Vecotr files are preferred in cardboard display industry by graphic desginers, since these are in very high quality and flexible to produce. Transfer all possible elements like fonts, logos into dots, then you get vector files.

It won’t degrade as you enlarger them, and is very high quality artwork.

File type PDF, AI, or EPS are most commonly used for vector artwork.

How to understand dieline template?

Dielines are necessary to assure the proper size and placement of art. Packwins will supply dieline template in the format of PDF, AI, eps, tec. Files will be sent via email.

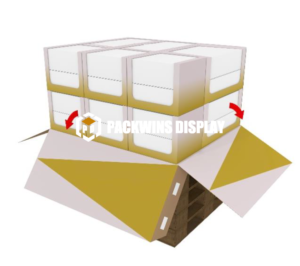

Different colors shall be applied to dielines for specific purpose. Take below a simple display box for example.

Cut and Folding Lines (Red Lines):

Indicate where the box will actually be cut on the outside lines, and inner side red lines are to be fold or crease. Important graphics and text should be placed at least 0.125 inches from the cut line.

Bleed Lines (Blue Lines):

Artwork should extend past the cut lines to the bleed line to ensure full coverage on the box. This blue line indicates where the drain section is located. Edge of the graphics should exceed this line.

Safety Lines: (Green Lines):

This green line is also called safety margin. All important componants (text, etc.) must remain within these lines to prevent being cut off. As an industry standard, all graphics should be placed at least 0.125 inches from the cut line unless your design is intended.

Perforated Lines (Dotted Black Lines):

This perforated lines are small holes punched to facilitate easy tearing usually for a shelf ready packaging display box.

Here below is a whole set of dielines prepared for an FSDU floortsand. You are sure to have no doubts when receiving dielines from our structural designers. Since in these designs, there are very clear indications on every details like flute direction, cardboard thickness, sides of the graphic to be applied, etc.

Who and how to prepare artwork?

Most of the case it’s you- our distinguished customer to get the artwork done. The correct art files per instructions below mentioned will allow the artwork proof to be generated with fast turnaround times.

- No changes of our dieline templates in dimension or direction. There will be flute orientation indicated in the template.

- Put in seperated layers for dieline and your artwork. Only artwork will be printed and layer of dieline will be deleted before printing.

- Have 1/8 inches bleed between artwork and dieline, and have 1/8 inner bleed between fonts graphics and cut/crease line unless it is intented.

- All fonts must be outlined or send fonts together with graphics.

- All images be in CMYK not RGB and embedded.

Or if you have no graphic designer and you don’t have time to outsourcing a brand design, we can help. Simply send anything available like your graphic elements and logo of your product. We can design from scratch with no extra cost.

How to export a PDF for a Heidelberg or Roland?

It is not the end when you have finished design your artwork. The second last step is to export your press ready file for printing machines which are often the case Heidelberg and Roland. You can export all elements into a PDF, AI, eps or etc. Make sure fonts, graphics, iamges are to be included.

- Resolution should be at least 300DPI.

- Convert text, logos, drawings etc to vector if possible.

How to transfer artowrk files?

- If using your FTP site, please provide your site address, login ID and password.

- You can also choose to host artwork via third party storage like Google Drive, Dropbox and Wetransfer, and share us a download link.