Everything You Need for

Custom Cardboard Displays

Packwins offers customized cardboard display solutions globally, leveraging industry experience to curate a convenient library of material options showcasing their capabilities.

Material

Liner Material

When it comes to cardboard displays, several types of printing paper are commonly used due to their balance of durability, print quality, and cost-effectiveness. Here are the most frequently used printing papers in cardboard displays:

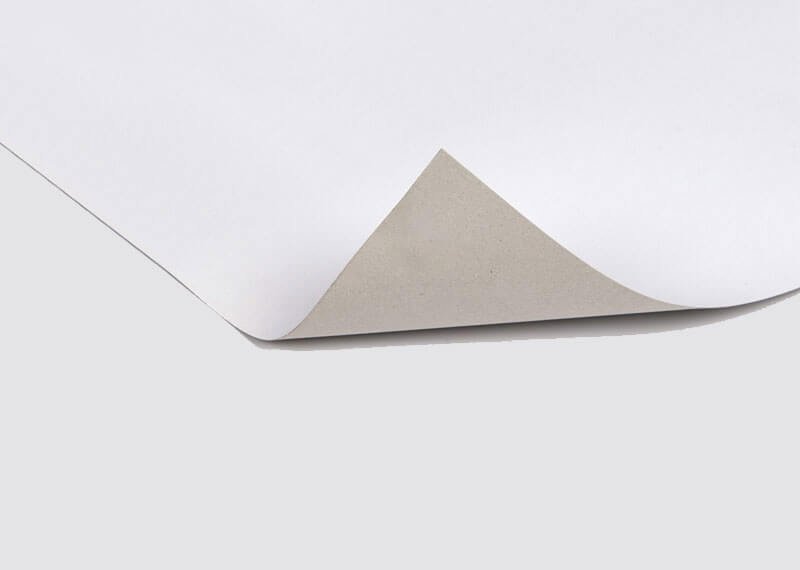

C1S

C1S paperboard is frequently used when one side of the display requires high-quality printing.

C2S

Both sides of the display are visible and need to present a high-quality image.

350G CCNB

Clay-coated surface while the back side is rough thus easy to pasted onto corrugate.

250G CCNB

A more cost-effective choice for budget-conscious projects or short-term use.

Gold Paper

Ferrero Rocher reflect the luxurious nature of the brand.

Corrugated Paper

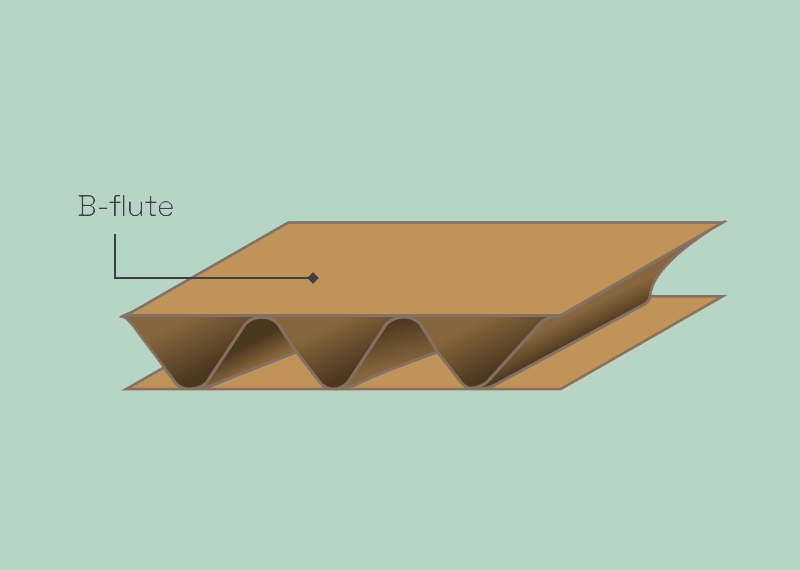

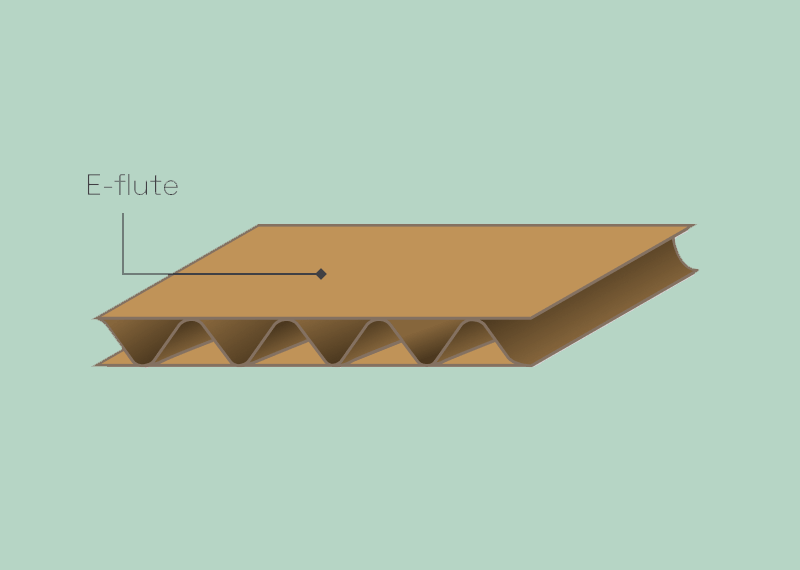

Corrugated paper is composed of fluted sheets sandwiched between flat linerboards, creating a rigid and cushioning effect that protects contents and maintains the integrity of the display. In the context of cardboard displays, three major types of corrugated flutes are commonly used: E flute, B flute, and EB flute.

B Flute

47 flutes per foot, used for larger footprint display like FSDU, etc.

E Flute

Approx 94 flutes per foot, used for smaller displays like counter displays.

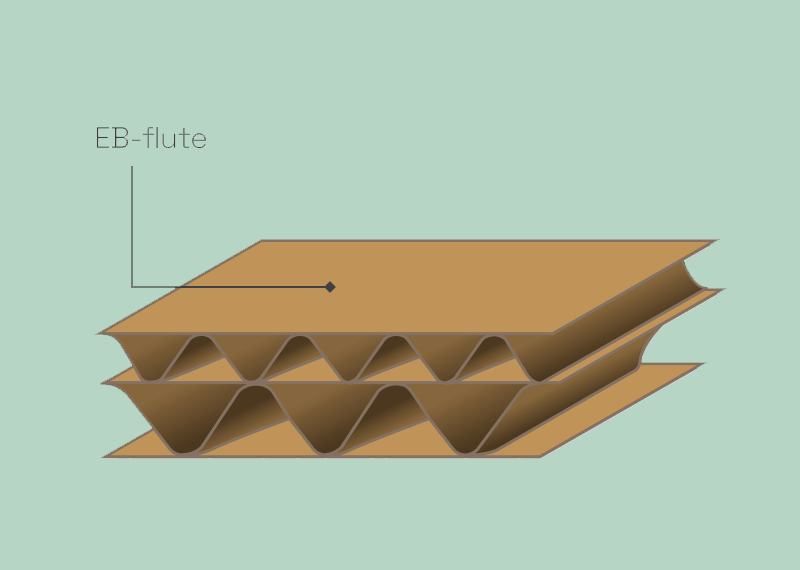

EB Flute

A combination of E and B flutes, used for heavy duty pallet displays.

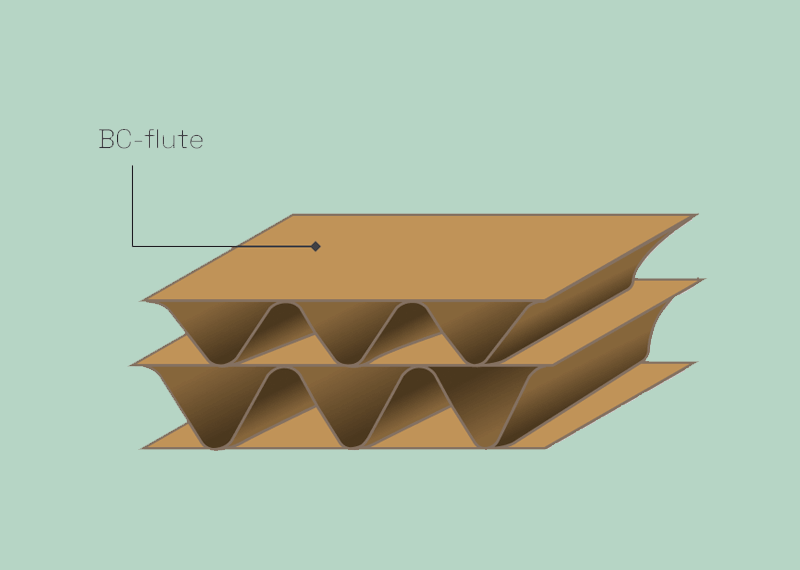

BC Flute

Double-wall construction combines B-flute and C-flute.

Spare Parts

Spare parts enhance the functionality, durability, and versatility of the displays, allowing them to meet specific needs and withstand various conditions. Here’s a closer look at some of the frequently used spare parts:

Double Arm Hooks

Product package with a wider hole to hangsell.

Butterfly Hooks

To showcase products that are best presented hanging.

Single Arm Hooks

Suitable for product package with a single hole.

Slatwall Hooks

Match the color of the display theme.

Metal Hooks

Suitable for heavy duty items.

Metal S Hooks

Attach hangsell display to store fixture.

U Clamp

To secure, support, or stabilize two parts of display.

Screw

Fix and connect parts together.

Plastic S hook

To attach sidekick displays to wireframe.

Wheels or Casters

Added to displays that require mobility.

Foot Pad

To protect the buttom of display from wet.

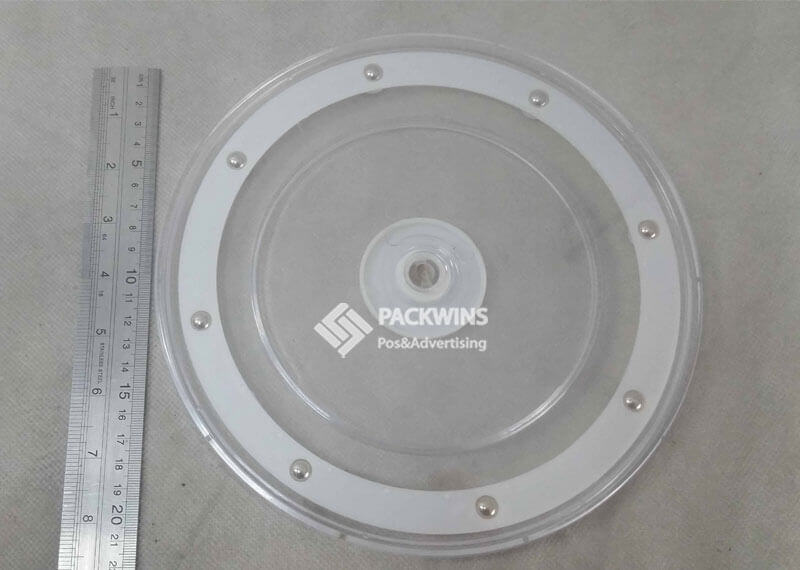

Turntable

Used in small counter display units.

Edge strip

To cover the corrugate edge and make a much perfect overall look.

Plastic clip

Serve as connectors or fasteners.

cable tie

Attach testing unit or other parts to display.

Metal Bar

Provide additional support for heavier loads.

Price Strip

Insert your price in this price strip.

Stopper

Used to fix products on hooks in transit.

Printing

Printing is a crucial process in a wide range of industries, from publishing and packaging to marketing and retail. Here’s an introduction to some common printing methods, including offset printing, lithography printing, digital printing, and aqueous printing:

Offset Print

High-quality prints and is cost-effective for large-volume runs.

Digital print

No need for printing plates. Perfect for display sample print.

UV Print

Use of ultraviolet light to cure or dry the ink instantly as it is printed.

Oil Base Ink

Traditional inks known for their rich color saturation and durability, used in offset printing.

Soy Ink

An eco-friendly alternative to traditional petroleum-based inks, made from soybeans.

Fluorescent Ink

Produce bright, glowing colors highly visible under black light.

Flexography

Print continuous patterns on rolls especially for master cartons.

Pantone

A standardized color matching system used in printing.

CMYK

Cyan, Magenta, Yellow, and Key (Black). It is the standard for full-color printing

Coating

Printed coatings enhance your cardboard display by providing additional protection and a refined finish.

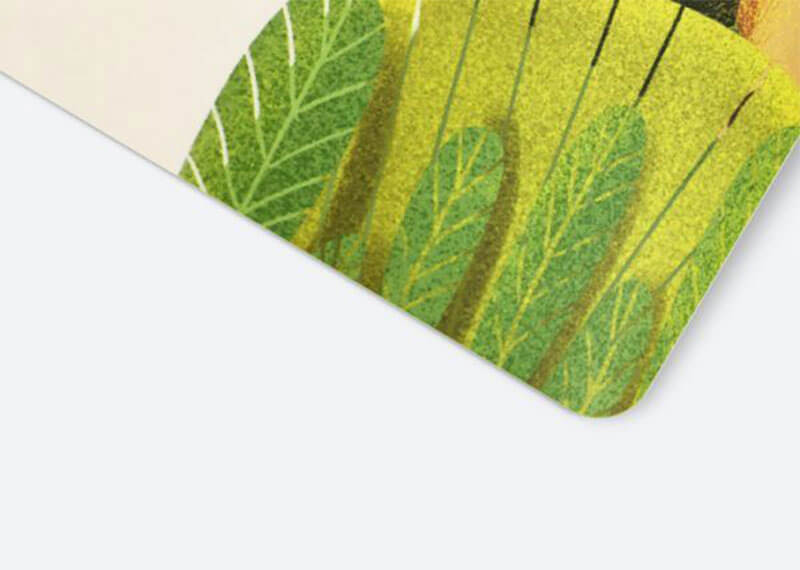

Gloss PP

Apply a glossy polypropylene film over printed materials, resulting in a shiny, reflective surface.

Matt PP

Applies a matte polypropylene film that gives printed materials a subtle, non-reflective finish.

Spot UV

A glossy, UV-cured coating is applied selectively to specific areas of a printed piece.

Aqueous coating

A water-based coating applied to printed materials to provide a protective layer that dries quickly.

Oil Varnish

Oil-based, gives it rich depth and a slightly glossy finish, enhancing the overall appearance.

Packing

Enhance the protection, presentation, and cost-effectiveness of your product’s journey from manufacturing to the end consumer. Based on your distribution plan, there are 3 main packing options.

Flat Packed into Carton

Individually packed and setup at retail stores.

Flat Packed onto Pallets

Consolidate with goods at local warehouse.

Consolidate Packing

Retail-ready, suitable for displays with small volumn.