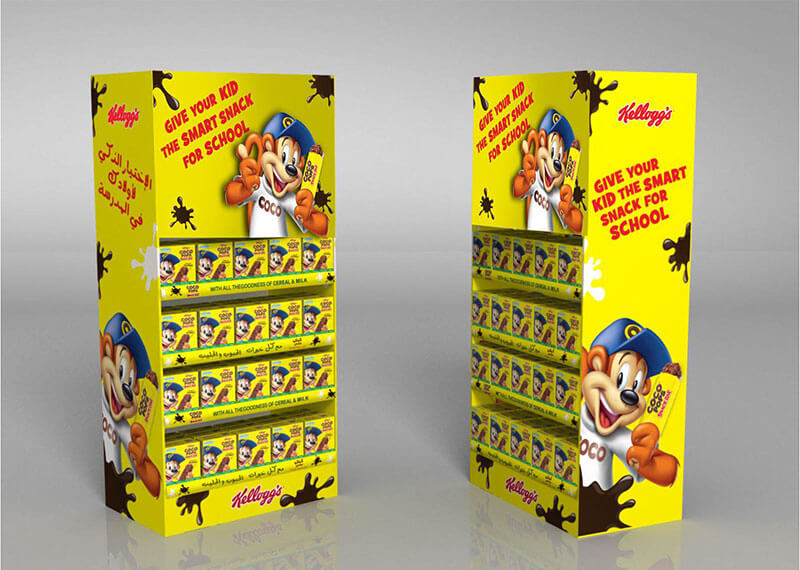

Custom Corrugated Endcap Displays

An Endcap Display is appropriately named for its placement at the end of an aisle at retail. It is thought the visibility of this space gives a brand a competitive advantage over the competition.

You will always see huge bulk items placed at the end of aisle with graphics to call to action. These endcap displays are widely used today in supermarket.

Table Of Contents For This Page

As an original manufacturer of corrugated endcap displays, we have communicated and worked for hundreds of brands including big box stores to bring their promotional scheme into reality. This elevate brands’ ROI and sell-through rates.

General Applications For Cardboard Endcap Displays

Corrugated endcap displays are often used to ship large volumes of products fully stock to retail stores. This is a popular forms of promotion especially for Big Box and Club Stores. Alternatively this can be packed KDF and assembled on site with easy setup guide.

POS Endcap Display Types

In order for easy transport, pallet displays are categorised into quarter, half and full palet. Pallet sizes vary between Euro and America, and club stores has its own specification limits especially overall height. Packwins cares for all the differences so that customers sleep at easy.

Waterfall Endcap

- Bring Your Brand to Life

- Huge stock areas

- Optional header

- Great weight bearing

Shape like a waterfall, the shelves could hold large stock quantity, thus it reduces refill possibility. Products facing shoppers to enable grab and go. An optional header showcases its brand identity.

Floor Stand End Cap

- Long lasting

- Low maintenance

- Cost efficient

- Easy to setup

One real benefit when using multi-celled display units is that you can promote an assortment of merchandise on one display. It’s an excellent means of maximising your retail footprint and they make for very eye catching units.

Graphic Wrap Endcap

- Convenience is the core

- grab-and-go

- ncourage a shopper to buy

- Match Your Brand’s Personality

In some of the cases, there only needs to wrap up the metal shelves, which we call it branding. This is a big saving when you compete in brick-and-mortal business. Stand out from the crowd by adding promotional graphics to the sides and header.

Wanna a complete range?

Estimated Cost Analysis For POS Endcap Displays

Cost of a POS Endcap Displays at manufacturer end can be break down into raw material and production cost. While at buyer’s ends, there are also shipping cost and tax factors to consider at landed cost. Kitting cost are something inbetween depends on where the displays are assembled.

Paper material cost - $800/T

Paper raw material price fluctuates from around $500/T in 2008 to $1200/T last year in 2021. For each display, the cost of paper depends mainly on the area of paper used. We design to maximize weight bearing capacity while minimize the amount paper used.

Printing cost - $0.3-1.5/print

Printing is very much a fixed cost. Assuming one KBA printing machine runs 24 hours a day with very stable running speed and skilled workman, the everage cost varies depend on sheet size from $0.3-1.5 per print.

Paper mounting and diecutting cost- $0.02-0.25/sheet

Besides the paper mounting and diecutting unit cost for each paper sheet, there will be a tooling cost for each cutting table at $25. Shared tooling cost lower down when quantity increases. This is the reason why most manufacturers welcome large qty.

Packing cost- $0-$2.5

There are 2 main types of packing for a corrugate pallet display depending on where and how the displays be assembled. Economic at manufacturer end is KDF (knock down off) flat packed onto pallets, or full assembled&consolidate with products.

Freight and shipping cost - $0.1-$3.5

Shipiping cost is the most uncontrollalble factor since COVID-19 broke out in 2020. Other than that we have find practical solutions to save shipping space and cut cost down. This need to be discussed case by case. Current average shipping cost would be $0.1-$3.5 2023.

The Process Flow & Duration Estimation

Here at Packwins we strive to minimize steps for a complete customized corrugate display order. From startup sketch design through prototyping, production and shipping. Each step shall be carried out under guidelines inhouse or brands&club stores’ standards.

Step 1: Idea Generate (1-2 days)

If you have or need a concept, we can assist you in making it a reality. We will walk you through and nail down the crucial variables to facilitate structural design by interacting with our experienced designer.

Step 2: Prototyping (1-2 days)

If you’re okay with the design, we’ll create a tangible sample. Before proceeding into large production, feel the sample with your hands. Particularly for a new client or project. This step helps save time and avoid issues at the first stage.

Step 3: Get Raw Material (1-3 days)

Once display structure and printing artwork been aproved by customer after reviewing sample, we shall issue PI for downpayment and start to prepare raw materials. Rolls for printing and corrugate core plate should be cut into size before production.

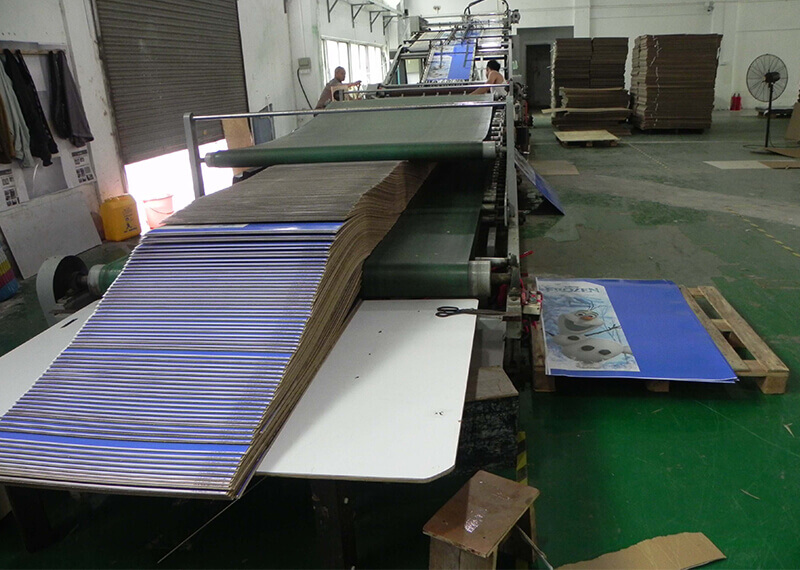

Step 4: Bulk Manufacturing (7-15 days)

As everything been nailed down and materials getting prepared, we start production from printing. Each sheet shall go through surface treating, paper mounting, diecutting, pasting and packing. Photos or videos shall be taken for customers to let you sleep at ease.

Step 5: Shipping (12-28 days)

Bookings be made in advance of the completion of the production. Air freight and maritime freight have different transit times. We’ll go over each case individually.

Want to know how to compress lead times?

In case you have an urgent order that need to be fulfilled less than our regular lead time, let’s discuss it here. There are alternative printing methods to offset, ie digital print direct to corrugate, and cut by laser cutting machine. Any thing is possible here.

The Basic Knowledge About POS Endcap Displays

While product and price point are important factors in any brand’s success, we help many brands achieve high sell-through percentages with packaging and pallet displays year after year — we’re part of a successful combo.

3PL Explained: How Third-Party Logistics Supports Retail-Ready Displays

Struggling with getting your retail displays to market? You’ve designed a brilliant display, but now it’s stuck in logistical chaos1, facing delays and retailer fines. The complexity of the supply chain is turning your launch

Spot Color Printing for Packaging & POP Displays

Your brand’s color is everything on a crowded retail shelf. Get it wrong, and you blend in. Get it right, and you stand out. But ensuring that perfect color match across thousands of displays feels

Co-Packing for CPG Brands: The Complete Guide

Getting your product ready for a major retail launch1 is tough. You have a great product, but getting it assembled into displays, perfectly labeled, and shipped to hundreds of stores on time feels like a

How to Design Endcap Displays Retailers Approve

Frustrated by retailers rejecting your endcap displays? It’s a common problem that costs time and money. Getting your design from concept to the sales floor requires navigating a maze of hidden rules. To get an

5 Dump Bin Display Mistakes to Avoid (and How to Fix Them)

Your dump bin display1 looks great, but it keeps collapsing under the weight of your products. This common problem can damage your merchandise and hurt your brand’s image. The right design and materials are crucial

PDQ Trays & Counter Displays: The Complete Guide

Struggling to get your products noticed in crowded retail stores? Your items get lost on the shelf, costing you valuable sales and brand recognition. It’s a constant battle for visibility. PDQ trays1 and counter displays2

What Is UV Coating in Retail Packaging Printing?

Your packaging finish feels…flat. You invested in great graphic design, but on the shelf, it just doesn’t pop. Worse, it scuffs easily, looking tired before it even reaches the customer. UV coating1 is a liquid

Flexographic Printing for Cardboard Packaging

Struggling to balance cost, speed, and quality for your high-volume packaging needs1? Finding the right printing method that scales effectively without compromising your brand’s look can feel like an impossible challenge. Flexographic printing is a

Litho Laminate vs. Digital vs. Offset Printing for Corrugated Displays

Struggling to choose the right printing for your displays? The options can be confusing, and a wrong choice impacts your budget and brand image. You need a cost-effective, high-quality solution1. The best printing method depends

How Short-Run Display Box Printing Saves Time and Money

You need to get a new retail display to market fast, but traditional printing quotes demand high volumes and long lead times. How do you test a new product without risking thousands on unproven packaging?

The Common Pitfalls When Purchasing

A variable factors in communication and execution can bring corrugate pallet display to be a failure. At Packwins we have taken notes on nagative factors from among the industry to avoid any in our practice so that clients like you sleep at ease.

- Miss communication on weight bearing

- Color inconsistence

- Screws&parts are not in place

- Display was not made under guidelines

- Failing To Maintain The Display

One of the crucial failure for a corrugate pallet display case in Cardboard Display industry we have heard about in the last 10 years was weight bearing capacity issue. This occurs ofen because of miscommunication and incorrect flute direction used when doing paper mounting.

Color consistence is another aspect that all brands and retailors care about. This is quite a technical part in printing. 2 main reasons that leads to color inconsistence. One is due to carelessness of printer who mistakenly ignored one or 2 colors, the other one is lack the ability.

Maintaining displays after drop shipping is as much important as the display design itself. Like the case in above second one, the curved shape came off from the main body. This can be done simply by shopkeepers to refill or check if every parts are in good condition. That won’t cost any extra penny.

Design of packing is vital during shipping. Taken all the parts for a single display into consideration, and stock height in the container properly so that no carton be crushed.

A Brief Self-Nomination, Why Choose Packwins?

Packwins is a structrual design, manufacturing and trading combo in point of purchase display industry. The key to our success in the early stage is design. Nearly every manufacturer can do with a box, but only a few can create a display with robust structure.

Packwins understands the paper industry from a sustainable development view. We respect the nature and environment and have a deep knowledge on paper material costing. This helps us keep our clients’ cost down.

- Consultative, understanding retail.

- Creative, award-winning structural design

- Great action, reliable in printing, manufacturing.

- Care for customers opinion, quick answer to client’s request.

We like to be involved in the early design stage of a pos pallet display. This way we both on the same line and gets 100% guarantee that what we’ve done meets up all your expectation.

The FAQs About Point of Purchase Endcap Displays

Customers are free to ask questions online, via email, since you are always be back up by a professional team at Packwins. Here below are some of the frequently asked questions to clear out your concerns and doubts.

- Have no idea?

Simply give us spec of your product. We can create packaging and display for you from scratch. You can review by digital designed prototype, and touch by hands with physical samples. - Have an idea?

That’s great! Our design team shall bring your idea into reality. Most often we need to improve the strctural design from clients to ensure its functionality and asthetics.

Yes.

Packwins has quite sophisticated workers doing printing, diecutting, pasting and packing for pallet displays. Strcture design is done in-house. Graphic design can also be provided upon request.

Euro (ISO O) Standard Pallet Sizes (cm)

- Full pallet: 80 by 120

- 1/2 half pallet: 80 by 60

- 1/4 quarter pallet: 60/40

American Standard Pallet Sizes (inch)

- 45-48″W x 40”D

- 48”W x 20”D

- 24”W x 20”D

Yes.

And we welcome you to consult at any stage of your display development. From early stage we shall created display rendering with different options for you to choose from. Strcture design shall be based on your product and product packaging features.

- 1-3 days

Qty<10pcs - 9-12 days

Qty<1000pcs - 15-20 days

Qty>1000pcs

No.

- Digital printing there is no tooling, so that no tooling charge at all. We print direct to corrugate for a fast turnaround time 1-2 days.

- Offset printing there should be tooling or diecutting mold, but we won’t add extra cost in quote, since this tooling helps bring average cost down.

- The best and safest to pay is via Telegraphic Transfer.

- Alternatively we accept paypal, westunion, credit card.

Yes.

Packing method shall be taking into consideration during the early structure design stage to save shipping pace and cost.

We can find competitive shipping rates and advice in the quote if you don’t have a shipping agent, or simply you would like to compare rates.

Sample cost refund when confirm bulk order.