Struggling to get your hardware product noticed on crowded retail shelves? You're not alone. Many brands create fantastic products but fail to consider the crucial journey from the factory to the customer's hands.

The solution lies in a holistic approach1 that integrates structural design2, branding, and retail execution from the very beginning. Effective hardware packaging protects the product, communicates brand value, and works seamlessly with in-store displays to grab customer attention and drive sales.

Getting a hardware product from the factory floor to a retail shelf is a complex journey. It's not just about creating a box; it's about engineering a complete system that ensures your product arrives safely, looks great, and sells effectively. I've guided countless brands through this process, and I want to share a case study that breaks down the essential steps. This journey involves careful planning, from defining your product's position in the market to designing shelf-ready packaging3 and eye-catching displays that stop shoppers in their tracks. Let's walk through how to turn a great product into a retail success story.

How to define Product Positioning and Retail Requirements?

Feeling lost in the competitive hardware aisle? Your product's packaging is its first handshake with the customer, and a weak grip won't cut it. Defining your retail strategy upfront is the only way to win.

The first step is to clearly define where and how your product will be sold. This involves identifying the target retailer, understanding shelf placement constraints, and determining the necessary level of product protection4. These initial decisions will shape every subsequent step of the packaging design process.

In this case study, our client developed a new line of heavy-duty steel shelf brackets. Their primary goal was to secure placement in big-box home improvement stores like Lowe's and The Home Depot. This immediately set clear parameters for our packaging strategy.

We started by analyzing the typical planogram5s for this category in these specific retailers. A planogram5 is the retailer's map for product placement, and ignoring it is a recipe for failure. We noted that products were often stocked on deep, industrial-style shelving, meaning the packaging needed to be structurally sound and easily identifiable from a distance. The brackets were heavy and had sharp corners, so robust protection was non-negotiable to prevent damage to the product and the packaging itself.

Key decisions at this stage included choosing a packaging format that could withstand stacking and rough handling. We also had to consider the unboxing experience6; customers for this type of product value straightforward, no-fuss packaging that allows them to see and feel the product's quality. Early constraints, such as the need for bilingual (English and Spanish) text and specific recycling information, were identified to ensure compliance with retailer requirements. This initial deep dive into the retail environment prevented costly redesigns later and set a solid foundation for a successful launch.

How to Develop Packaging Concepts That Balance Protection and Branding?

Worried your product will arrive damaged or be ignored on the shelf? Finding the sweet spot between robust protection and powerful branding is a common struggle, but it's one you can overcome with a strategic approach.

With a clear understanding of the retail requirements, the next phase is to develop packaging concepts that effectively balance product protection4 with brand messaging. This involves exploring different structural design2s and materials while ensuring the packaging communicates the product's unique selling propositions.

For the steel shelf brackets, we explored several structural packaging concepts. The weight and shape of the product made a simple poly-bag or thin paperboard box unsuitable. We needed a solution that offered superior protection while also providing ample space for branding and product information.

Our team developed three distinct concepts, each with its own trade-offs in terms of protection, branding real estate7, and cost. A key consideration was the visibility of the product. While fully enclosing the brackets offered maximum protection, it hid their high-quality finish and sturdy construction. Conversely, a more open design could enhance shelf appeal but increased the risk of damage.

Ultimately, we decided on a hybrid approach: a heavy-duty corrugated tray that held the brackets securely, combined with a printed sleeve that provided branding space and key product information. This concept offered excellent protection, allowed customers to see and touch the product, and was cost-effective for mass production. This decision was crucial for retail readiness, as it met the durability requirements of the big-box environment while creating an attractive and informative presentation on the shelf.

Packaging Concept Options

| Concept Type | Protection Level | Branding Space | Cost Impact |

|---|---|---|---|

| Fully Enclosed Corrugated Box | High | Excellent | Moderate |

| Corrugated Tray with Shrink Wrap | Moderate | Limited | Low |

| Corrugated Tray with Sleeve | High | Good | Moderate |

| Blister Pack on Card | Moderate | Good | High |

How to Prototype and Test Packaging for Durability and Retail Readiness?

Anxious about your packaging failing during shipping or in the store? Prototyping and rigorous testing are your insurance against costly disasters. Don't leave the durability of your packaging to chance.

Once a packaging concept is selected, it's critical to create physical prototypes and subject them to a battery of tests. This phase validates the design's durability and ensures it can withstand the rigors of the supply chain and the retail environment.

For our shelf bracket project, we created several production-quality prototypes of the corrugated tray and sleeve design. These weren't just mockups; they were made from the exact materials we planned to use for the final production run. This allowed us to conduct realistic performance tests.

We simulated the entire journey from the factory to the retail shelf. This included a series of drop test8s from various heights and angles to assess the packaging's ability to protect the brackets from impact. We also performed compression test9s to ensure the packages could withstand being stacked on a pallet without crushing.

Beyond physical durability, we simulated the retail experience. We stocked the prototypes on actual store shelving to evaluate their stability and ease of handling for retail associates. We also conducted user testing with a small focus group to gauge their impressions of the packaging and the unboxing experience6. The feedback was invaluable, leading to a minor adjustment in the sleeve's design to make it easier to remove. This thorough testing phase gave us the confidence that our packaging was not only durable but also truly retail-ready, preventing potential issues that could have jeopardized the product's launch.

Packaging Test & Validation Checklist

| Test Type | Purpose | Pass/Fail Risk |

|---|---|---|

| Drop Test | Simulates accidental drops during shipping and handling. | Product or packaging damage. |

| Compression Test | Ensures packaging can withstand stacking on pallets. | Crushing of the package, damaging the product. |

| Vibration Test | Simulates transportation conditions. | Product abrasion or breakage. |

| Retail Handling Simulation | Assesses ease of stocking and handling for store staff. | Difficulty in stocking, leading to poor shelf presentation. |

How to Scale Production: Materials, Specifications, and Quality Control?

Ready to go from a single prototype to thousands of units? Scaling up production can be daunting, with many potential pitfalls. A detailed plan for materials, specifications, and quality control is your roadmap to success.

With a validated prototype, the next step is to scale up for mass production. This involves finalizing material specifications, defining the printing methods, and establishing rigorous quality control checkpoints10 to ensure consistency across the entire production run.

For the steel shelf brackets, we finalized the specifications for all packaging components. The corrugated tray required a specific flute type and board strength to support the weight of the product. The sleeve needed a high-quality paperboard with a clay coating to ensure vibrant and durable printing.

We chose offset printing for the sleeve to achieve the high-quality graphics necessary to stand out in a competitive retail environment. We also added a matte varnish11 to protect the print from scuffs and scratches during transit and handling.

Quality control was a top priority throughout the production process. We established checkpoints at every critical stage, from the inspection of raw materials to the final assembly of the packaging. We created a detailed checklist for our manufacturing partner, specifying acceptable tolerances for color accuracy, print registration, and dimensional accuracy. This meticulous attention to detail ensured that every package that came off the production line met our high standards and was ready for the retail shelf. By avoiding inconsistencies in production, we protected the brand's reputation and ensured a uniform, professional appearance in stores.

Final Packaging Specifications

| Component | Material | Thickness / Grade | Reason Chosen |

|---|---|---|---|

| Tray | Corrugated Board | B-Flute, 32 ECT | Excellent strength-to-weight ratio for product support. |

| Sleeve | Coated Paperboard | 18pt C1S | Smooth surface for high-quality printing and durability. |

| Varnish | Matte UV Coating | N/A | Protects print and reduces glare under store lighting. |

How to Prepare Shelf-Ready Packaging and Retail Displays for In-Store Success?

Is your product just sitting on the shelf, or is it actively selling? The final, crucial step is turning your packaged product into a compelling in-store presentation. Shelf-ready designs and POP displays are what transform shoppers into buyers.

The final piece of the puzzle is preparing the packaged product for the retail floor. This involves designing shelf-ready packaging3 (SRP) and integrating it with point-of-purchase (POP) displays to maximize visibility and drive sales.

For the shelf brackets, we designed the corrugated tray and sleeve system to function as shelf-ready packaging3. The outer shipping carton had a perforated tear-away panel, allowing retail associates to quickly open the case and place the ready-to-sell trays directly on the shelf. This significantly reduces stocking time and ensures a neat, consistent presentation.

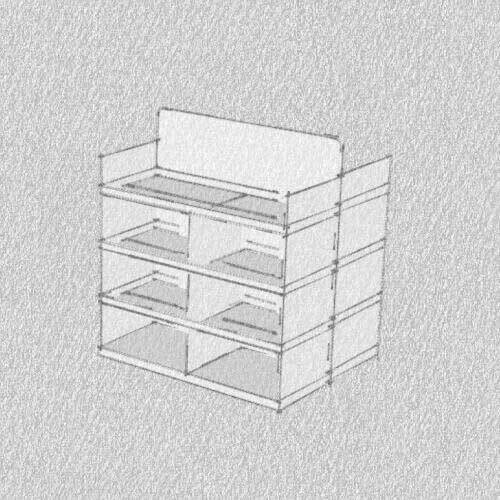

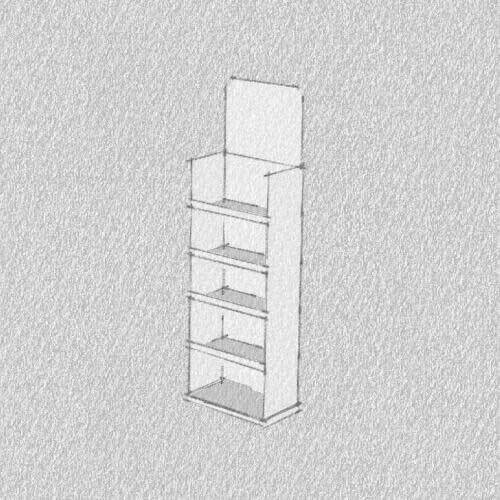

To further boost visibility for the product launch, we developed a corrugated floor display. Corrugated cardboard is an ideal material for POP displays because it is lightweight, cost-effective, and incredibly versatile. We engineered the display to be structurally sound, capable of holding the weight of dozens of bracket packages without buckling. The display was shipped flat-packed to the stores and could be easily assembled in minutes without any tools.

The floor display provided a large canvas for branding and educational messaging, highlighting the key features and benefits of the brackets. Placing these displays in high-traffic areas of the store, like main aisles and endcaps, ensured that the new product launch couldn't be missed. This integrated approach of combining shelf-ready packaging3 with a strategic POP display was instrumental in the product's successful sell-through.

POP Display Considerations for Retail Hardware

| Display Type | Best Use Case | Material | Retail Benefit |

|---|---|---|---|

| Floor Display | New product launches, high-traffic areas. | Corrugated Cardboard | Maximizes visibility and branding space. |

| Endcap Display | Promotions and seasonal items. | Corrugated Cardboard | Captures attention at the end of aisles. |

| Pallet Display | Bulk items and club stores. | Corrugated Cardboard | High volume, easy to shop. |

| Counter Display | Small items and impulse buys. | Corrugated Cardboard | Drives last-minute purchases at checkout. |

From Factory to Shelf: Execution Overview

| Stage | Key Decision | Packaging Impact | Retail Outcome |

|---|---|---|---|

| 1. Define Requirements | Target big-box retailers; heavy product. | Required durable, stackable packaging. | Met retailer compliance and prevented damage. |

| 2. Develop Concepts | Chose a tray-and-sleeve design. | Balanced protection, branding, and cost. | Created an attractive, informative package. |

| 3. Prototype & Test | Conducted drop and compression test9s. | Validated structural integrity. | Ensured packaging survived the supply chain. |

| 4. Scale Production | Finalized material specs and QC checks. | Ensured consistent quality. | Maintained brand image and consistency in-store. |

| 5. Retail Execution | Designed SRP and corrugated floor displays. | Reduced stocking time and boosted visibility. | Drove high sell-through and a successful launch. |

Conclusion

Ultimately, successful retail hardware packaging requires a holistic strategy. By planning design, materials, and displays together from the start, you avoid costly downstream issues and ensure your product is ready for retail success.

Understanding a holistic approach can help you integrate design, branding, and execution for better product visibility and sales. ↩

Learn how structural design can protect your product and enhance its shelf presence, crucial for retail success. ↩

Discover how shelf-ready packaging can streamline stocking and enhance product presentation in stores. ↩

Ensure your product arrives undamaged and maintains its quality, which is vital for customer satisfaction and brand reputation. ↩

Understanding planograms can help you optimize your product's shelf placement and visibility in retail stores. ↩

Explore how a positive unboxing experience can enhance customer satisfaction and brand loyalty. ↩

Maximize your packaging's branding space to effectively communicate your product's unique selling points. ↩

Learn how drop tests ensure your packaging can withstand shipping and handling, preventing product damage. ↩

Understand how compression tests help ensure your packaging can handle stacking and prevent crushing. ↩

Ensure consistent quality in your packaging production to maintain brand reputation and customer satisfaction. ↩

Learn how matte varnish can protect your packaging's print and reduce glare, improving its appearance in stores. ↩