Struggling to budget for packaging design1? You fear overspending on a design that doesn't connect, or under-spending and getting a cheap look. This guide breaks down the real costs.

The final cost of packaging design depends on the project's scope, complexity, required deliverables, and manufacturing process2. A simple visual design is much cheaper than a full structural and visual package engineered for mass production and retail success. On average, expect costs from $500 to over $5,000.

I've seen too many brands focus only on the initial design quote, thinking they've snagged a bargain. But the true cost of packaging design isn't just a fee you pay a designer. It's a strategic investment3 that ripples through your entire business, affecting everything from your manufacturing costs and shipping efficiency to how your product performs on a crowded retail shelf. Thinking about design in isolation is one of the fastest ways to lose money. Let’s walk through what you’re really paying for, so you can make a smarter decision that boosts your bottom line.

What Factors Actually Determine the Cost of Packaging Design?

Wondering why one design quote is triple another? The details of your project, not just the designer's rate, are what truly drive the final price of the project.

Packaging design cost is determined by scope, complexity, deliverables4, and how the packaging will be produced and sold. Visual design alone is cheaper than packaging engineered for manufacturing and retail success, which requires deeper expertise.

The price you pay is a direct reflection of the work required. For instance, a startup with one simple product for e-commerce has very different needs than a mature brand with 50 SKUs heading into big-box retail. The latter requires a much more robust design system. Product complexity also plays a huge role; a simple box for a t-shirt is straightforward, but a fragile electronic device needs intricate structural design and testing. The number of SKUs directly multiplies the design and setup work. Finally, packaging designed for Walmart or Costco has to meet strict retail compliance standards5 for shipping and shelving, which adds a layer of engineering that a simple direct-to-consumer box doesn't need. Each of these factors adds layers of work, and therefore, cost.

How Packaging Design Costs Vary by Product Type and Industry?

Your industry dictates your packaging needs. A food product has different rules and material requirements than a cosmetic item, and these specific demands directly impact the design investment.

Packaging design costs vary widely by industry due to regulatory, structural, and retail requirements. For example, food packaging must meet safety compliance, while cosmetics often require premium materials to signal quality.

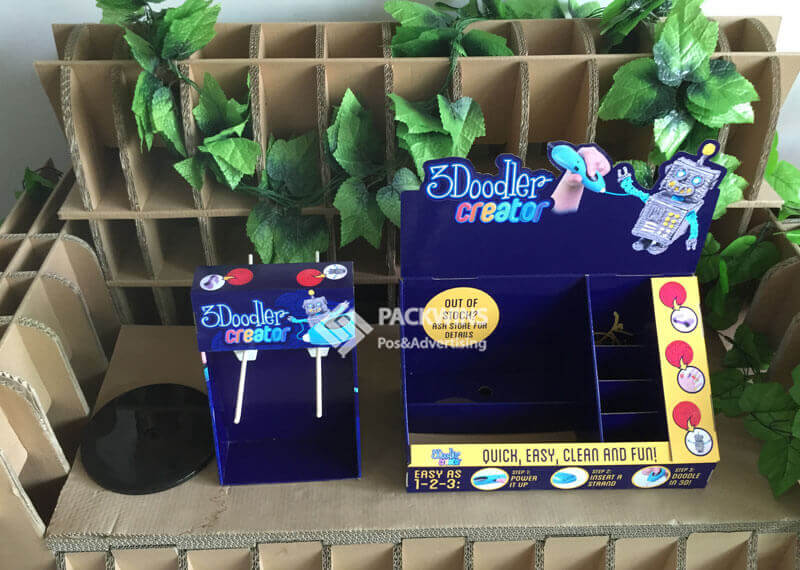

The differences in cost come from industry-specific needs6. Food and beverage products require adherence to FDA guidelines and often need specialized materials to ensure freshness and safety. Beauty and cosmetics packaging relies heavily on perceived value, using premium materials, complex finishes like foil stamping, and unique structural designs to stand out. Regulated products like CBD have strict labeling and child-resistant requirements, adding complexity. And retail POP displays7 are a whole different beast; they must be structurally sound to hold products, visually compelling to stop shoppers, and engineered for easy assembly in-store. These unique demands require specialized expertise, which is reflected in the cost.

| Product Type | Typical Design Cost Range |

|---|---|

| Simple consumer goods | $500 – $2,500 |

| Food & beverage packaging | $2,000 – $6,000 |

| Beauty & cosmetics | $3,000 – $10,000 |

| CBD / regulated products | $4,000 – $12,000 |

| Retail POP packaging & displays | $5,000 – $20,000+ |

Freelancer vs Agency vs Full-Service Partner: How Pricing Differs?

Choosing your design partner is a critical decision. Are you just buying a graphic, or are you investing in a retail-ready product system? The answer changes who you should hire.

Who you hire dramatically impacts both cost and outcome. While freelancers seem cheaper upfront, their lack of manufacturing knowledge can lead to expensive production errors. A full-service partner aligns design with production from day one.

Your choice of a design partner directly influences your total project cost and, more importantly, your success. A freelancer might give you a great-looking visual for a low price, but they rarely understand the technical side of production. This often results in designs that are difficult or expensive to manufacture. A design agency brings more strategic branding power but often hands off the design files, leaving you to figure out production. I operate as a full-service partner, meaning my team handles everything from initial concept to structural engineering and final production. This integrated approach ensures the design is not only beautiful but also optimized for efficient manufacturing and ready for the rigors of retail environments.

| Provider Type | Typical Cost | Strengths | Limitations |

|---|---|---|---|

| Freelancer | Low | Speed, flexibility | Limited production insight |

| Design Agency | Medium–High | Brand strategy | Often design-only |

| Full-Service Partner | Higher upfront | Design + production alignment | Not ideal for tiny projects |

What's the Difference Between Visual Design Costs and Structural Design Costs?

Ever seen a beautiful box that falls apart? That's what happens when you only pay for visual design and ignore the structure. One makes it look good; the other makes it work.

Visual design focuses on appearance—graphics, colors, and branding—while structural design ensures the packaging actually works in production, shipping, and retail. One is about attraction, the other about performance.

Many brands mistakenly believe packaging design is just about graphics. That's visual design. It's the branding, the colors, and the typography that grab a customer's attention. But structural design is the unseen hero. It’s the engineering that determines the physical shape, material, and construction of the package. This includes creating the dielines (the blueprint for cutting the cardboard), ensuring the box can withstand stacking pressure on a pallet, survive drops during shipping, and fit perfectly into a retail POP display. For corrugated displays, structural integrity is everything. Without proper engineering, a display can collapse in-store, leading to lost product and a damaged brand reputation.

What are the hidden Costs Brands Overlook in Packaging Design Projects?

Your initial design quote is rarely the final price. Many brands get blindsided by unexpected expenses that emerge after the design is "finished," turning a budget-friendly project into a costly problem.

Many packaging projects exceed their budget due to overlooked costs beyond the initial design quote. These often stem from a design that isn't optimized for manufacturing, shipping, or retail compliance.

I've seen brands burn through thousands on costs they never saw coming. A common one is redesigns after the package fails ISTA drop tests or is rejected by a retailer for not meeting compliance standards. Another major hidden cost is freight inefficiency. A poorly designed package that doesn't maximize pallet space can dramatically increase your shipping expenses over time. And if your product packaging isn't designed to integrate seamlessly with your retail POP displays7, you'll face fulfillment issues, in-store assembly problems, and potential chargebacks from retailers8. These "hidden" costs are almost always a result of separating the design process from the realities of production and logistics.

How Revisions, Prototypes, and Testing Impact Total Design Cost?

Think you can save money by skipping prototypes? This is one of the most expensive mistakes you can make. Every revision and test you skip early on will cost you ten times more down the line.

Revisions and prototyping are essential for a successful launch, but unmanaged iteration can significantly increase total cost. A structured process of mockups, physical prototypes, and production testing prevents costly failures.

The design process should be iterative, but those iterations need to be managed. Starting with digital mockups allows for quick, low-cost visual adjustments. Once the look is approved, a physical prototype is crucial. This is where you test the structural integrity. Does it hold the product securely? Can it be assembled easily? Skipping this step is a gamble that can lead to total structural failure on the shelf. Finally, production testing ensures the design can be manufactured consistently at scale and meets all retailer requirements, like fitting properly into their shelf displays. Each stage has a cost, but it's an investment in risk mitigation. Finding a problem at the prototype stage is cheap; finding it after you've produced 50,000 units is a catastrophe.

| Stage | Cost Impact | Risk if Skipped |

|---|---|---|

| Digital mockups | Low | Poor brand clarity |

| Physical prototype | Medium | Structural failure |

| Production testing | Medium–High | Retail rejection |

When Higher Packaging Design Costs Deliver Better Long-Term ROI?

Viewing packaging design as a cost is a short-term mindset. Viewing it as an investment is how you build a scalable, profitable brand that succeeds in the competitive retail landscape.

A higher initial investment in packaging design often reduces production waste, logistics damage, and retail failures, resulting in a significantly better long-term ROI. It's about spending smart upfront to save big later.

Strategic design is about value, not cost. When your packaging is engineered for manufacturing, your production costs are lower with less material waste. When it's designed for the supply chain, you have fewer damages and more efficient shipping. When it's designed for retail, you get faster approvals from buyers at stores like Target and Walmart, and your products perform better on the shelf. This is especially true for corrugated POP displays, where good design balances cost, durability, and in-store impact. A cheap design might save you a few thousand dollars today, but a strategic design that is aligned with production and retail execution can save you tens of thousands in the long run by preventing costly redesigns, chargebacks, and delays.

| Investment Level | Short-Term Cost | Long-Term Outcome |

|---|---|---|

| Low | Cheap design | Redesigns, damage, delays |

| Medium | Balanced | Acceptable retail performance |

| Strategic | Higher upfront | Faster scale, better ROI |

Conclusion

Packaging design is a critical business decision, not just a cosmetic one. The cheapest design often becomes the most expensive over time. Brands that align design with production and retail win.

Understanding how to budget for packaging design can help you avoid overspending or under-spending, ensuring a design that connects with your audience. ↩

Learning about the manufacturing process's impact on costs can guide you in selecting designs that are efficient to produce. ↩

Exploring why packaging design is a strategic investment can reveal its impact on manufacturing, shipping, and retail success. ↩

Understanding these factors can help you anticipate costs and choose the right design approach for your product. ↩

Knowing these standards ensures your packaging meets retailer requirements, avoiding costly redesigns and rejections. ↩

Exploring industry-specific needs helps you understand the unique demands and costs associated with your product's packaging. ↩

Understanding retail POP displays can help you design packaging that stands out and performs well in retail environments. ↩

Understanding chargebacks helps you avoid penalties and ensure your packaging meets retailer expectations. ↩