You need to get a new retail display to market fast, but traditional printing quotes demand high volumes and long lead times. How do you test a new product without risking thousands on unproven packaging?

Short-run display box printing1, powered by digital technology2, is the solution. It allows you to produce small quantities of high-quality displays quickly and affordably. This process eliminates the need for expensive printing plates and lengthy setup times, making it perfect for market tests3, prototypes4, and seasonal promotions5.

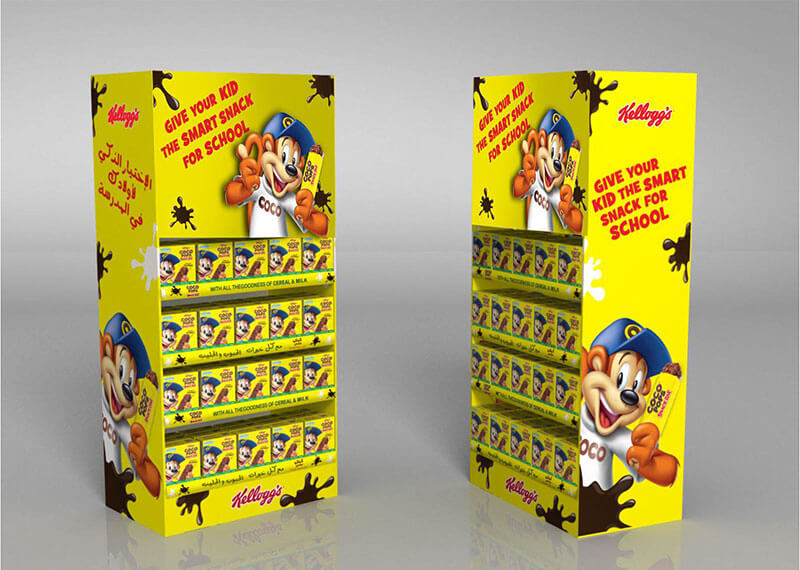

I've seen too many great product launches stumble right at the finish line. A brand will have an amazing product, a solid marketing plan, and eager retailers, but their point-of-purchase displays6 hold them back. Traditional printing methods often force a tough choice: order a massive quantity you don't need or delay your launch. This is precisely the problem short-run printing solves. It offers a strategic advantage that goes beyond just printing fewer boxes; it changes how you approach retail altogether. Let’s explore how this technology gives you the speed and flexibility needed to win at the shelf.

Faster Turnaround7 for Prototypes, Tests, and Retail Launches

You have a tight deadline for a retail launch, but your display provider says it will take weeks just to get a prototype. Every day you wait is a day you’re not selling. This delay can kill your momentum.

With short-run digital printing, you can get prototypes4 and final displays in a fraction of the time. Since digital printing doesn't require printing plates, the setup is incredibly fast. This means you can move from a design file to a physical sample quickly, getting your product on shelves sooner.

In the world of retail, speed is everything. A competitor can beat you to the punch, or a trend can fade before your display even hits the floor. Traditional offset printing, with its reliance on creating physical plates and complex machine setups, can take weeks. For a brand manager trying to launch a seasonal product or test a new market, that’s an eternity. This is where Packwins’ short-run printing model removes friction. We use advanced digital printing technology that allows us to produce high-quality corrugated displays with lead times as short as 5-7 business days. Imagine having a prototype in your hands to test and refine within days, not weeks. This rapid iteration cycle means you can perfect your display based on real-world feedback before committing to a larger run, ensuring your retail launch is as effective as possible.

Lower Upfront Costs8 and Reduced Inventory Risk9

Traditional printers often require a high minimum order quantity (MOQ)10, forcing you to invest heavily in displays you haven't tested. This creates a huge financial risk and can lead to piles of outdated, wasted displays.

Short-run printing allows you to order as few as 100 units, drastically lowering your initial investment. This "print-to-need" model eliminates the risk of overproduction and saves you from costly storage and obsolescence, preserving your budget for other marketing efforts.

One of the biggest pain points I hear from brand managers is the risk associated with large MOQs. Offset printing is only cost-effective for large jobs, often requiring orders of 500 pieces or more. If a new product launch doesn't perform as expected or a retailer changes its merchandising guidelines, you could be left with thousands of dollars’ worth of useless cardboard. Packwins allows brands to test displays without committing to full-scale risk. Our digital printing process makes low MOQs not just possible, but practical. You can order exactly what you need for a pilot program or a limited-time offer. This approach significantly reduces inventory risk and waste. Instead of your capital being tied up in display inventory sitting in a warehouse, you can invest it in refining your product and marketing, making smarter, data-driven decisions for your brand.

Greater Design Flexibility Without Expensive Plate Changes11

You've just received a thousand displays, but the retailer wants a last-minute design change. With traditional printing, this means paying for new plates and potentially another full print run, a costly and time-consuming setback.

Digital printing offers incredible design flexibility12, as changes can be made directly to the digital file with no penalty. You can easily update artwork, create different versions for specific retailers or regions, or even personalize displays without incurring expensive plate fees.

Retail environments are dynamic, and display designs often need to adapt. A promotion might change, a new SKU might be added, or a retailer might request specific branding. With traditional offset printing, every single change, no matter how small, requires a new set of printing plates. This process is not only expensive but also adds significant delays. This is where Packwins’ expertise in digital color printing on corrugated and cardboard materials becomes a game-changer. Our system allows for effortless artwork updates. We can produce multiple design variations within the same run, enabling you to create targeted displays for different stores, regions, or even languages. This capability is perfect for seasonal campaigns or A/B testing different marketing messages on the shelf. You get the freedom to optimize your display's effectiveness without being penalized for making smart, agile marketing decisions.

Smarter Scaling13 From Short Runs to Full Retail Rollouts

You ran a successful pilot with short-run displays, but now you're worried the quality won't be consistent when you scale up to a national rollout. This fear often forces brands into costly and unnecessary redesigns.

A strategic partner will engineer your short-run display for scalability from the start. This ensures a seamless transition from a small pilot to mass production, maintaining consistent quality and structural integrity without costly re-engineering.

The transition from a pilot program to a full-scale retail rollout is a critical moment, and it's where many brands encounter problems. A display that worked for a small test run might not be engineered for the rigors of mass production and a complex supply chain. This misalignment can lead to production delays, increased costs, and a final product that doesn't match the quality of the prototype. At Packwins, we act as the bridge between your prototype, pilot, and national rollout. We engineer every display, even a short-run prototype, with scalability in mind. We consider material strength, ease of assembly, and shipping efficiency from day one. This foresight ensures that when you're ready to scale, the transition is seamless. You don't have to start over. The same high-quality printing and structural integrity from your initial run are replicated, ensuring brand consistency across every single store.

Short-Run Digital Printing vs. Traditional Offset Printing14

| Factor | Short-Run Digital Printing | Traditional Offset Printing14 |

|---|---|---|

| MOQ | As low as 100 units | 500+ units |

| Setup Cost | Very low to none (no plates) | High (printing plates required) |

| Lead Time | 5-10 business days | 2-4 weeks or more |

| Design Changes | Easy and inexpensive | Costly and time-consuming |

| Ideal Use Case | Prototypes, market tests3, seasonal runs | Large, high-volume rollouts |

Cost Impact Comparison15 for Display Box Printing

| Cost Area | Short-Run Printing | Offset Printing | Retail Risk if Misaligned |

|---|---|---|---|

| Upfront Investment | Low | High | High (Wasted capital on unproven displays) |

| Inventory & Storage | Minimal | High | Medium (Costs of storage and potential obsolescence) |

| Design Revisions | Low to None | High | High (Inability to adapt to market feedback) |

| Speed to Market16 | Fast | Slow | High (Missed sales opportunities and competitor advantage) |

Conclusion

Short-run printing is more than a low-volume option; it's a strategic advantage. It allows you to test faster, make smarter retail decisions, and reduce risk. The real savings come from avoiding costly mistakes, not just a lower unit price. Packwins helps you move faster without being locked into them.

Explore how short-run display box printing can revolutionize your retail strategy with quick, affordable, and high-quality solutions. ↩

Discover the role of digital technology in making short-run printing efficient and cost-effective for retail displays. ↩

Learn how market tests can minimize risks and optimize product launches with real-world feedback. ↩

Understand the importance of prototypes in refining product designs before full-scale production. ↩

Find out how seasonal promotions can boost sales and brand visibility in retail environments. ↩

Explore the impact of point-of-purchase displays on consumer buying decisions and retail success. ↩

Discover the advantages of faster turnaround times in getting products to market quickly and efficiently. ↩

Understand how reducing upfront costs can minimize financial risks and support agile marketing strategies. ↩

Learn how reduced inventory risk can save costs and prevent waste in retail operations. ↩

Find out how high MOQs can lead to financial risks and inefficiencies in retail display production. ↩

Learn about the costs and delays associated with plate changes in traditional printing methods. ↩

Discover the importance of design flexibility in adapting to market changes and consumer preferences. ↩

Explore how smarter scaling ensures consistent quality and efficiency from prototypes to full rollouts. ↩

Understand the constraints of traditional offset printing and how it affects retail display production. ↩

Learn how comparing costs between printing methods can guide strategic decisions in retail. ↩

Discover how getting products to market quickly can capitalize on trends and outpace competitors. ↩