What is Shelf & Retail Ready Packaging?

SRP&RRP help your team save time, make your products stand out, and give your customers a smoother shopping experience.

SRP (Shelf-Ready Packaging):

Packaging that simplifies the process of stocking and displaying products directly on retail shelves. It follows the “Five Easies”—easy to identify, open, shop, replenish, and dispose of.RRP (Retail-Ready Packaging):

A broader term encompassing all packaging formats ready for immediate placement in retail environments. RRP focuses on operational efficiency and consumer convenience, including display-ready trays, cartons, and merchandising units.

Table of Contents (Guide to Custom SRP&RRP Displays)

What are the benefits of Shelf-Ready Packaging?

- The Five Easies of SRP

Identify: Retail employees can quickly recognize products in storage for efficient placement on shelves.

Open: Packages require minimal effort to open, eliminating the need for tools like knives or box cutters.

Shop: Products are easy for customers to spot and grab, enhancing the shopping experience.

Replenish: Restocking is fast and simple, reducing labor and saving time.

Dispose: Packaging is designed for quick removal, easy recycling, and minimal waste. - Adapting to Consumer Trends: Meeting demands for convenience and sustainability.

- Improving Brand Perception: Creating a visually appealing and functional retail presence.

- Supporting Seasonal Promotions: Tailored solutions for limited-time offers or events.

Types of SRP & RRP Solutions

Cardboard trolley expo boxes are quite simply categorised into 2 types based on their handle, one is corrugate material which can be done as a one-piece with the box main body, another is with a seperate plastic handle. Box sizes vary based on individual requirement.

Shelf Trays: Corrugated cardboard trays with removable covers.

- Easy Stocking and Display

- Enhanced Product Visibility

- Customizable Design

- Cost-Effective and Lightweight

Trays can be tailored to specific product dimensions and printed with branding elements, enhancing your product’s retail presence.

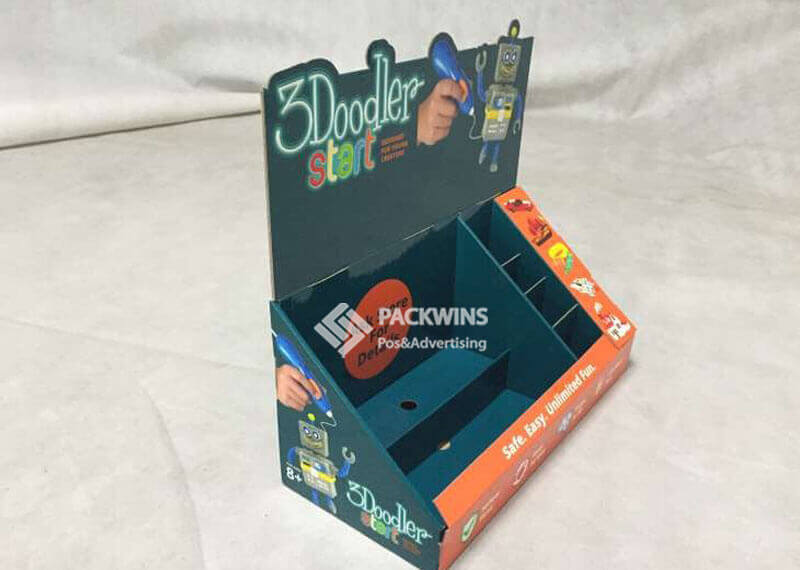

Merchandising Units: Freestanding displays for promotions or high-demand items.

- Freestanding Design

- Customizable Branding

- Versatile Configurations

- Easy Assembly and Transport

Easily positioned anywhere in the store, providing flexibility for high-traffic or strategic areas to maximize visibility. Designed to hold various product sizes and quantities, accommodating seasonal promotions or high-demand items.

Wanna a complete range?

Estimated Cost Analysis For SRP&RRP

Cost of a POS shelf ready packaging display at manufacturer end can be break down into raw material and production cost. While at buyer’s ends, there are also shipping cost and tax factors to consider at landed cost. Kitting cost are something inbetween depends on where the displays are assembled.

Paper material cost - $800/T

Paper raw material price fluctuates from around $500/T in 2008 to $1200/T last year in 2021. For each display, the cost of paper depends mainly on the area of paper used. We design to maximize weight bearing capacity while minimize the amount paper used.

Printing cost - $0.3-1.5/print

Printing is very much a fixed cost. Assuming one KBA printing machine runs 24 hours a day with very stable running speed and skilled workman, the everage cost varies depend on sheet size from $0.3-1.5 per print.

Paper mounting and diecutting cost- $0.02-0.25/sheet

Besides the paper mounting and diecutting unit cost for each paper sheet, there will be a tooling cost for each cutting table at $25. Shared tooling cost lower down when quantity increases. This is the reason why most manufacturers welcome large qty.

Packing cost- $0-$2.5

There are 2 main types of packing for a corrugate pallet display depending on where and how the displays be assembled. Economic at manufacturer end is KDF (knock down off) flat packed onto pallets, or full assembled&consolidate with products.

Freight and shipping cost - $0.1-$3.5

Shipiping cost is the most uncontrollalble factor since COVID-19 broke out in 2020. Other than that we have find practical solutions to save shipping space and cut cost down. This need to be discussed case by case. Current average shipping cost would be $0.1-$3.5 2023.

What to consider from design to production?

From design to production, Packwins ensure your Shelf-Ready Packaging (SRP) and Retail-Ready Packaging (RRP) not only meet retail standards but also showcase your brand’s appeal and enhance functionality, driving greater sales opportunities for your products.

Step 1: What do I need for this SRP?

1. What type of product am I displaying?

Understanding your product is the first step in designing an effective SRP. Consider:

Shape: Is it rectangular, round, or irregular?

Weight: Does it require sturdy materials for support?

Packaging style: Is it individually wrapped, in bottles, or boxed?

2. Who is my target audience?

Your display needs to resonate with the end consumer. Reflect on:

Demographics: Who are they—age, preferences, buying habits?

Visual appeal: What colors, styles, or features catch their attention?

Convenience: How can the design enhance their shopping experience?

3. What retail guidelines do I need to follow?

Retailers often have specific requirements for displays. Ask about:

Shelf dimensions: What is the maximum height, width, and depth?

Weight restrictions: Are there limits to how heavy the display can be?

Branding regulations: Does the retailer have rules about logos or messaging?

4. What size and dimensions should the display be?

Getting the size right ensures a perfect fit on shelves and prevents overcrowding. Consider:

Product arrangement: How many items will the display hold, and how will they be arranged?

Ease of stocking: Can the display be easily restocked by store employees?

Visibility: Will the display stand out to customers at eye level or from a distance?

5. How many units should each display hold?

Finding the right balance between display capacity and stocking efficiency is key. Think about:

Sales velocity: How quickly do you expect products to sell?

Retailer preferences: Do stores prefer smaller or larger displays?

Shipping efficiency: Does the number of units per display optimize shipping costs?

These questions form a strong foundation to guide the development of a successful retail shelf-ready display.

Step 2: Define Your Budget

Establishing a clear budget is crucial for a successful Shelf-Ready Packaging (SRP) program. A well-planned budget ensures that your project remains efficient and goal-oriented while aligning with your financial resources and sales objectives.

Key Factors to Consider

Start by evaluating the economics of your entire process:

Product Pricing and Profit Margins: Align your packaging costs with your product’s price point and expected profit margins.

Projected Sales: Estimate how long your packaging will be in use and the sales volume it will support.

Packaging and Shipping Costs: Account for expenses like packaging materials, shipping boxes, and any fillers required for product protection.

Additional Resources and Services

Consider whether you need third-party assistance, such as:

Contract Packagers: These can handle fulfillment and assembly, saving you time and resources.

Turnkey Solutions: Partnering with companies offering comprehensive services can help streamline the process and minimize costs.

Volume Purchasing and Scalability

Leverage economies of scale to optimize your budget:

Bulk Purchasing: While buying in larger quantities reduces per-unit costs, it requires upfront investment and considerations for storage and handling.

Digital Printing Options: For smaller batches, digital printing offers flexibility and reduces waste, allowing you to adjust designs or quantities as needed.

Balancing Costs and Value

Finally, balance your investment with your product’s value and market positioning. Higher-priced products may warrant greater investment in premium packaging to enhance their perceived value and shelf appeal.

By carefully defining your budget and planning each element, you can ensure your SRP program remains both cost-effective and impactful.

Step 3: Design a Shelf-Ready Packaging

When sourcing Retail-Ready Packaging (RRP) from China, creating a design that aligns with your brand and meets retailer expectations is essential. Your packaging should stand out on shelves, be easy to handle, and support operational efficiency. Here’s how to approach the design process:

Brand Visibility

Focus on the elements of your brand that must be immediately recognizable to customers:

Logo and Tagline: Ensure your brand identity is prominent and memorable.

Brand Colors and Fonts: Use consistent visuals that reinforce your branding.

Product Imagery: Include high-quality images to showcase your product.

Key Information: Highlight your company story, product benefits, or other relevant details.

Display Configurations

Decide how your product will be presented to maximize shelf appeal and convenience:

Branded boxes with separate packages inside.

Shelf trays with removable tops for easy stocking.

Reusable plastic trays for durable and eco-friendly solutions.

Freestanding merchandising units or stackable designs for bulk displays.

Optimizing Design for Efficiency

Stackable Design: Prioritize designs that allow cartons to be stacked for efficient use of shelf space. A two-carton-per-SKU capacity per shelf helps streamline restocking, minimizing downtime.

Shelf and Pallet Optimization: Simple adjustments to package configuration can improve space utilization and reduce waste.

Retail Compliance and Customer Ease

Retail Standards: Ensure branding is visible on all sides and opening instructions are included for easy handling by retail staff.

Consumer-Friendly Design: Create packaging that helps customers quickly identify, grab, and purchase products without hassle.

Global Market Adaptations

For packaging distributed across multiple retailers or regions, plan for alternate designs to meet varying market standards and compliance requirements.

Professional Support

If you lack in-house design expertise, partnering with a packaging supplier offering creative services can streamline the process. Many Chinese suppliers provide end-to-end solutions, including award-winning design teams, to bring your vision to life.

By designing thoughtful and strategic packaging, you not only meet retail and customer needs but also enhance your brand’s impact in competitive markets.

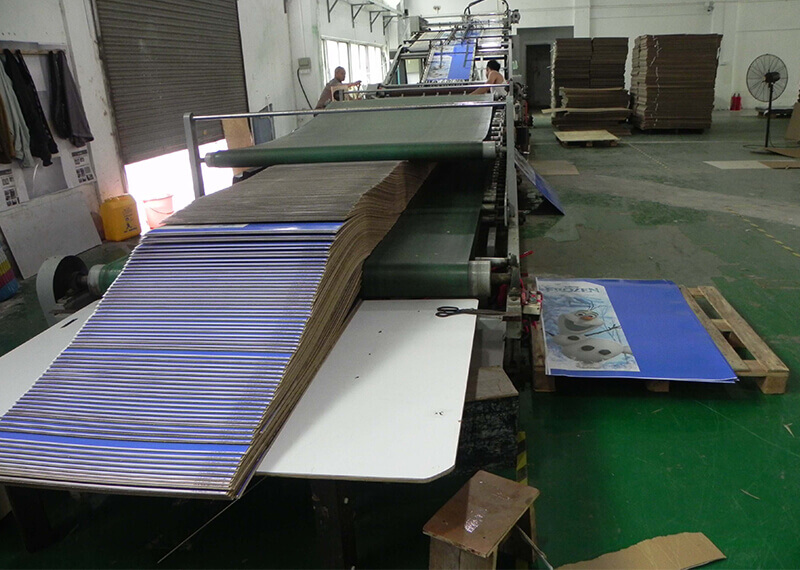

Step 4: Printing and Surface Treatment

Choose the Right Printing Method

Flexographic printing: Ideal for large runs with simple designs and cost-effective results.

Digital printing: Perfect for complex graphics, vibrant colors, and smaller batches with frequent updates.

Select the Appropriate Surface Treatment

Matte finish: Provides a sleek, premium look.

Glossy finish: Enhances color vibrancy and visual appeal.

Aqua Coating: A water-based, eco-friendly option that delivers a smooth finish and enhances durability.

UV coatings or laminations: Protect against moisture, scratches, and fading during transit and handling.

Ensure Consistency in Branding

Share detailed design files with your supplier.

Use color accuracy standards like PMS or CMYK to maintain brand consistency.

By planning your print and surface treatment meticulously, your SRP and RRP packaging can captivate customers, strengthen your brand presence, and deliver practical benefits like durability and sustainability.

Step 5: Packwins Creates a Dieline

A dieline is a template that shows how your Shelf-Ready Packaging (SRP) or Retail-Ready Packaging (RRP) will be cut and folded.

At Packwins, we create a custom dieline to match your product’s size and display needs.

We take into account your product’s dimensions, weight, and how it will be displayed on shelves. Our dieline includes all necessary fold lines, cut lines, and bleed areas to make sure everything fits and works as planned.

Step 6: Artwork Design

Artwork design is a crucial step in the creation of your Shelf-Ready Packaging (SRP) or Retail-Ready Packaging (RRP).

It involves designing the visual elements of your packaging, including your logo, product images, colors, and any text that communicates your brand and product information.

Effective artwork design can help attract attention on store shelves, reinforce your brand identity, and provide clear information to consumers.

Step 7: Prototyping and Testing

You can request a prototype display before mass production. This helps ensure your packaging meets all design and functional requirements.

Customers check samples by photos via email or to courier the sample and touch them by hands.

At Packwins, we use advanced cutting table to quickly work out on a prototype, allowing you to move quickly from design to productio

Step 8: Production + Shipping

Once the prototype is approved, the next step is full-scale production.

At this stage, your Shelf-Ready Packaging (SRP) or Retail-Ready Packaging (RRP) is produced in bulk. This involves printing, cutting and packing based on the finalized dieline and artwork.

Logistic solutions

By working with reliable suppliers and logistics partners, you can optimize lead times, reduce costs, and ensure consistent quality. Streamlining inventory management and using technologies like tracking systems can provide real-time updates and prevent delays.

Key Questions:

- Will your displays be shipped knock-down-off or fully assembled with your products?

- What is the weight of the simgle package since couriers has restriction on sizes?

- If there is fullfilment cost?

Key Things to Monitor

It’s important to track your packaging inventory to ensure it meets demand. Keep a close eye on the stock at your fulfillment center to determine if it’s sufficient for the season’s needs.

Have you ever run out and needed to purchase more? Did this result in delays or additional costs?

On the other hand, did you have excess inventory? Was it limited to specific sizes?

Regularly monitoring your packaging levels and aligning them with demand can help prevent shortages or overstocking.

Want to know how to compress lead times?

In case you have an urgent order that need to be fulfilled less than our regular lead time, let’s discuss it here. There are alternative printing methods to offset, ie digital print direct to corrugate, and cut by laser cutting machine. Any thing is possible here.

Key Questions When Sourcing from China

Sourcing Shelf-Ready Packaging (SRP) and Retail-Ready Packaging (RRP) from China offers great value but involves many crucial steps. Each decision impacts the quality, cost, and efficiency of your packaging solution.

This section covers key questions to guide you through supplier selection, design, production, shipping, and import processes. Addressing these will help you make informed choices and find the right supplier for your needs.

Supplier Selection and Credibility

- Verifying supplier reliability and certifications.

- Evaluating experience and specialization in SRP/RRP.

- Ensuring compliance with international standards.

Design and Customization

- Options for customization (dimensions, branding, materials).

- Availability of prototyping and mockup services.

- Meeting retail shelf requirements and sustainability needs.

Pricing and Payment

- Cost breakdown and bulk order discounts.

- Payment terms, methods, and security options.

Production and Quality Control

- Typical production lead times.

- Quality assurance processes during manufacturing.

- Flexibility for urgent or customized timelines.

Logistics and Shipping

- Available shipping methods and estimated delivery times.

- Packaging for shipment (flat-packed, palletized).

- Shipping terms: FOB, CIF, EXW, DDP, etc.

- Tracking shipments and handling delays/damage.

Import Tax and Customs

- Customs clearance responsibilities and documentation.

- Understanding import taxes, duties, and associated fees.

- Availability of DDP (Delivered Duty Paid) services.

- Calculating total costs, including taxes and shipping.

Communication and Support

- Availability of a dedicated contact person.

- Resolving issues or disputes effectively.

- After-sales support for long-term partnerships.

Risk Mitigation

- Importance of consolidating shipments to save costs.

- Balancing shipping speed and cost.

- Proactive steps to avoid customs or shipping issues.

A Brief Self-Nomination, Why Choose Packwins?

Packwins is a structrual design, manufacturing and trading combo in point of purchase display industry. The key to our success in the early stage is design. Nearly every manufacturer can do with a box, but only a few can create a display with robust structure.

Packwins understands the paper industry from a sustainable development view. We respect the nature and environment and have a deep knowledge on paper material costing. This helps us keep our clients’ cost down.

- Cost-efficiency

- Customization capabilities

- Experienced manufacturers

- Care for customers opinion, quick answer to client’s request.

We like to be involved in the early design stage of a pos SRP&RRP display. This way we both on the same line and gets 100% guarantee that what we’ve done meets up all your expectation.

The FAQs About Shelf & Retail Ready Packaging

Customers are free to ask questions online, via email, since you are always be back up by a professional team at Packwins. Here below are some of the frequently asked questions to clear out your concerns and doubts.

- Have no idea?

Simply give us spec of your product. We can create packaging and display for you from scratch. You can review by digital designed prototype, and touch by hands with physical samples. - Have an idea?

That’s great! Our design team shall bring your idea into reality. Most often we need to improve the strctural design from clients to ensure its functionality and asthetics.

Yes.

Packwins has quite sophisticated workers doing printing, diecutting, pasting and packing for pallet displays. Strcture design is done in-house. Graphic design can also be provided upon request.

Euro (ISO O) Standard Pallet Sizes (cm)

- Full pallet: 80 by 120

- 1/2 half pallet: 80 by 60

- 1/4 quarter pallet: 60/40

American Standard Pallet Sizes (inch)

- 45-48″W x 40”D

- 48”W x 20”D

- 24”W x 20”D

Yes.

And we welcome you to consult at any stage of your display development. From early stage we shall created display rendering with different options for you to choose from. Strcture design shall be based on your product and product packaging features.

- 1-3 days

Qty<10pcs - 9-12 days

Qty<1000pcs - 15-20 days

Qty>1000pcs

No.

- Digital printing there is no tooling, so that no tooling charge at all. We print direct to corrugate for a fast turnaround time 1-2 days.

- Offset printing there should be tooling or diecutting mold, but we won’t add extra cost in quote, since this tooling helps bring average cost down.

- The best and safest to pay is via Telegraphic Transfer.

- Alternatively we accept paypal, westunion, credit card.

Yes.

Packing method shall be taking into consideration during the early structure design stage to save shipping pace and cost.

We can find competitive shipping rates and advice in the quote if you don’t have a shipping agent, or simply you would like to compare rates.

The style of packaging chosen for your product depends on a number of factors. This includes the size, shape, weight, and fragility of your product – and even your target market. At Bennett, we can offer the full spectrum of styles that will take your brand from plain to premium.

Packwins offers a wide variety of shelf-ready packaging boxes, including folding cartons, mailing boxes, and shipping boxes. No matter what kind of product you have, or box you need, we can make it. Just Contact Us and we’ll get back to you ASAP!