Guide to Sams Club and Costco Pallet Displays will help you through your retail marketing compaign. Pallet displays play a crucial role in driving sales and enhancing the shopping experience in warehouse clubs like Sam’s Club and Costco.

These displays not only showcase products effectively but also adhere to specific guidelines that optimize their functionality and visual appeal.

This guide dives deep into the requirements, best practices, and trends for creating pallet displays tailored to these retail giants.

Sam’s Club Packaging Process

Pre-selection Stage:

-All suppliers should be prepared with the initial packaging intake sheet during initial meetings. Sam’s packaging team will not review the items until they are closer to commitments unless specific support is needed.

When Items Are Closer to Commitments:

-Complete the Intake Sheet to include the packaging details as well as the pallet configuration.

-Once completed, please forward the sheet to Sam’s Club Packaging for review.

-Preferred packaging suppliers are available to help with detailed packaging design, as needed.

ISTA Distribution Testing:

For Sam’s US and Mexico, use the ISTA-6SC testing protocol.

For Sam’s Dotcom, Sam’s modified 6-FEDEX is required.

-A “Pass” rating from the test is necessary before final approval is granted on the packaging and pallet configuration. This approval is also required before Sam’s Club can authorize shipments to begin.

-Sam’s Club authorizes shipments based on testing performance. Authorization does not remove any liability from the Product Supplier or the Packaging Supplier, as per previously signed contracts with Sam’s Club.

-Suppliers should review all details in this document and the complete Sam’s Club Packaging Standards. Suppliers know the details of their product and supply chain and must incorporate this knowledge into the recommendations for their final packaging.

For detailed information, please access the Retail Link site map and search for “Sam’s Club Packaging Standards.”

Sam’s Club Packaging Best Practices

When designing your packaging soution, you should consider if it meets these criteria:

Easy to Identify: Is the associate able to visually locate your product in the steel or in the back room when resotcking?

Easy to Open: Can the case be quickly and safely opened without additional tools?

Easy to Shop: Is the product easily removed from the pallet and not trapped by secondary packaging? Are all of the product varieties accessible?

Easy to Dispose: Are material recyclable, reusable by the member or easy to break down? Have you added How2Recycle labeling?

Certainly! Here is the information arranged in a table format:

| Sam’s DC | In-Club Execution | Member Facing | Member Use | |

|---|---|---|---|---|

| Easy to Identify | ||||

| Easy to Open | ||||

| Easy to Shop | ||||

| Easy to Dispose |

Sam’s Club General Display Criteria

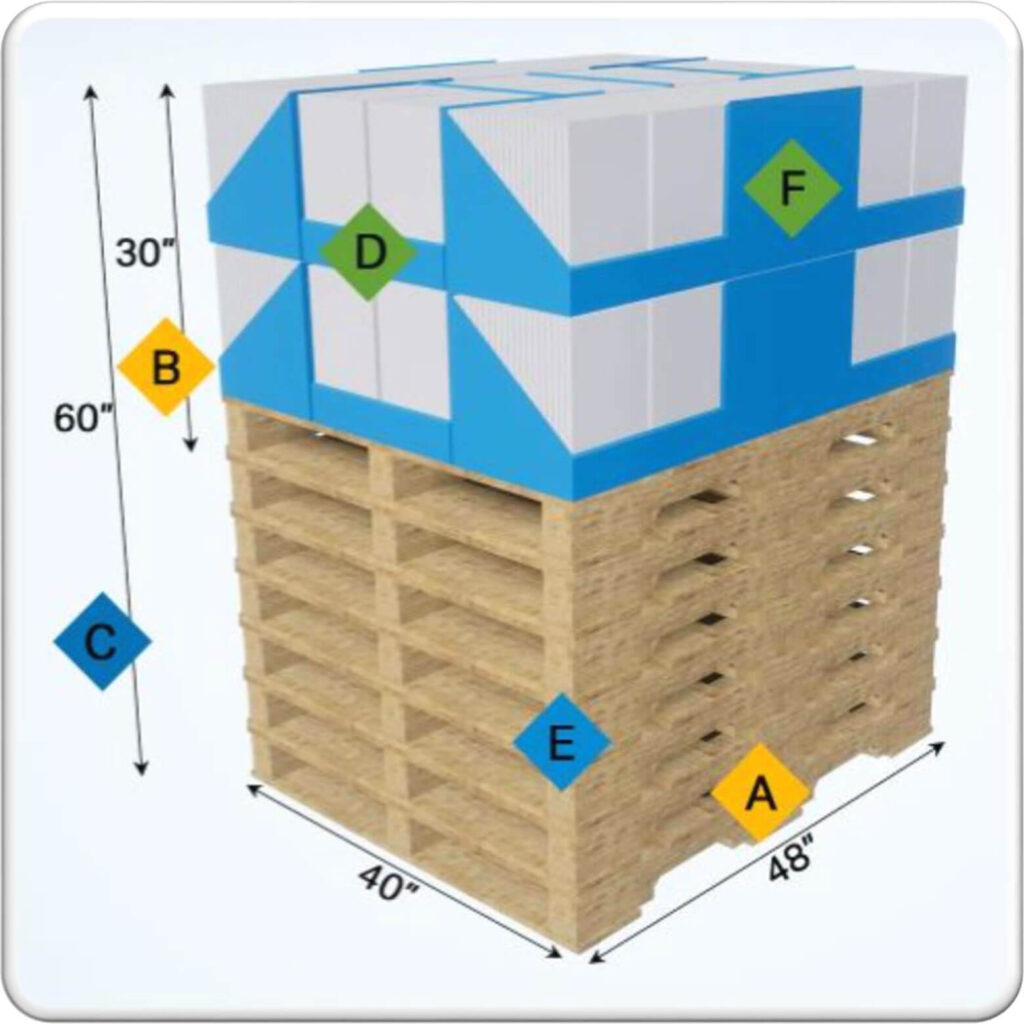

A. Pallet Requirements:

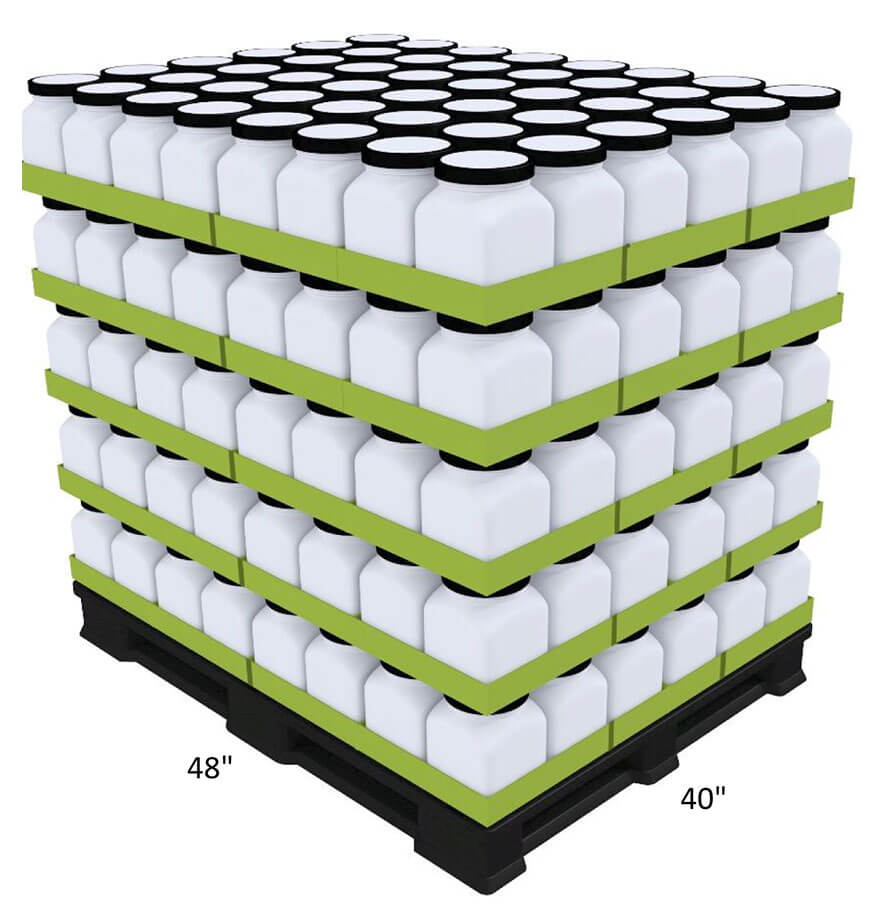

-Must be a Grade A 40”x48” GMA Hardwood Pallet with a maximum loaded weight of 2,100 lbs.

-CHEP, PICO, RM2, and IGPS pallets are also acceptable.

-Block pallets are required for pallets over 2,100 lbs.

B. Minimum Distribution Height:

-The minimum distribution height is 30” including the pallet, unless otherwise specified.

C. Maximum Distribution Height:

-The maximum distribution height is 52” including the pallet, unless otherwise specified.

D. Shoppability:

-Trays of products should be member-facing when displayed at the club.

-The pallet must be shoppable from three sides; however, consult category guidelines for any exceptions.

E. Display Base Structure:

-False bottoms are not acceptable.

-Pallet skirts are not acceptable.

-Extra pallets will be provided in the club as needed.

F. Display Filler:

-Fillers should be utilized when additional graphic space is needed or when the product does not fully cube a pallet.

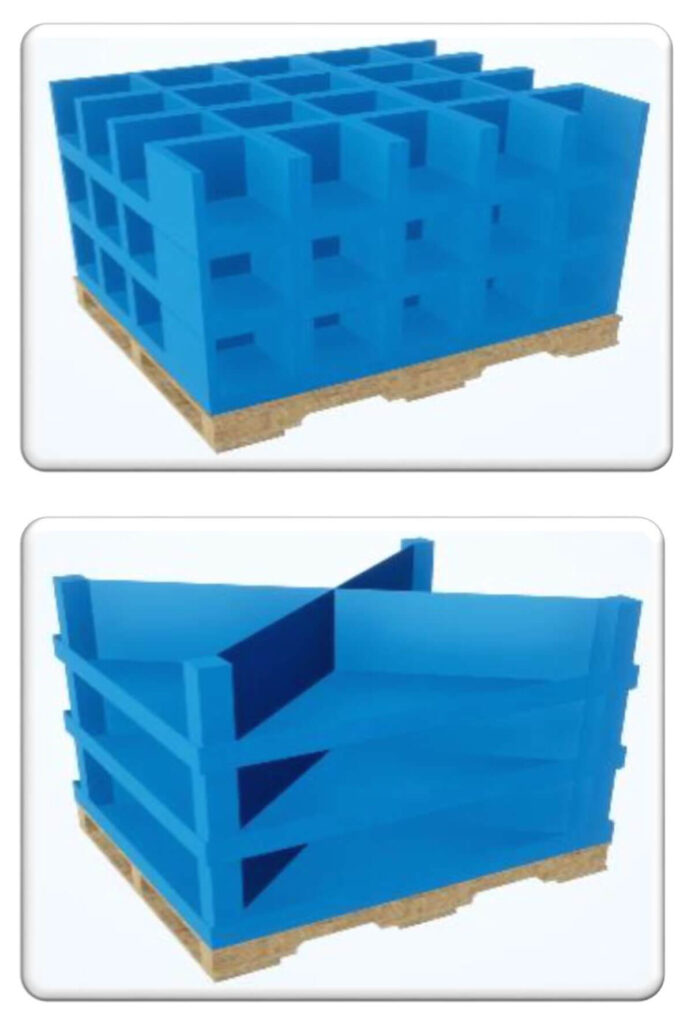

Sam’s Club PDQ Display Stacking Features

A stacking feature is an element of the display design which adds strength and stability.

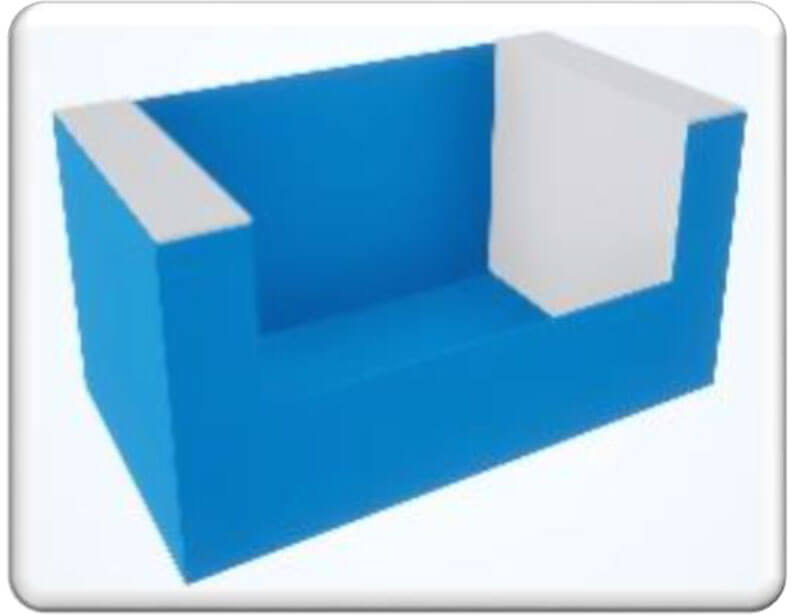

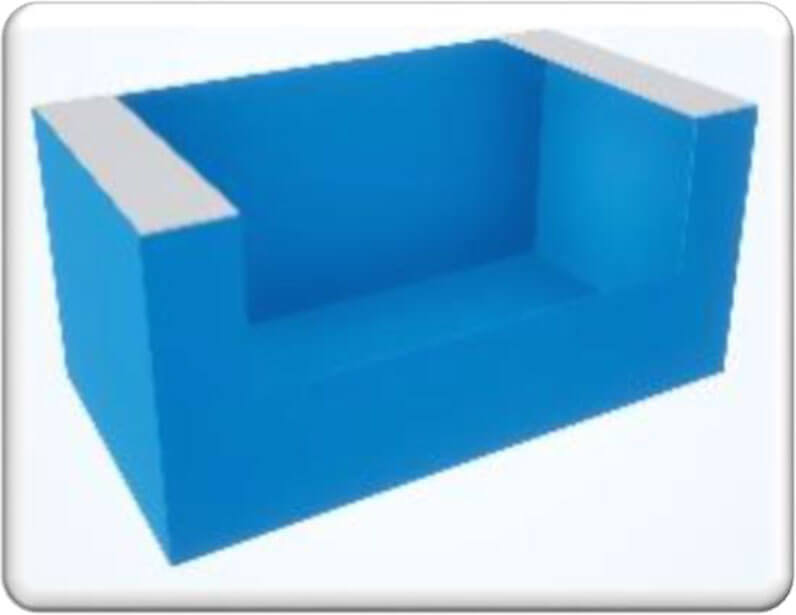

PDQ Fillers

A filler is an additional compnent folded and added to the tray to add additional structure.

Corner Supports

Corner supports can be accomplished a variety of ways but all span the corners of these case to add stability and strength.

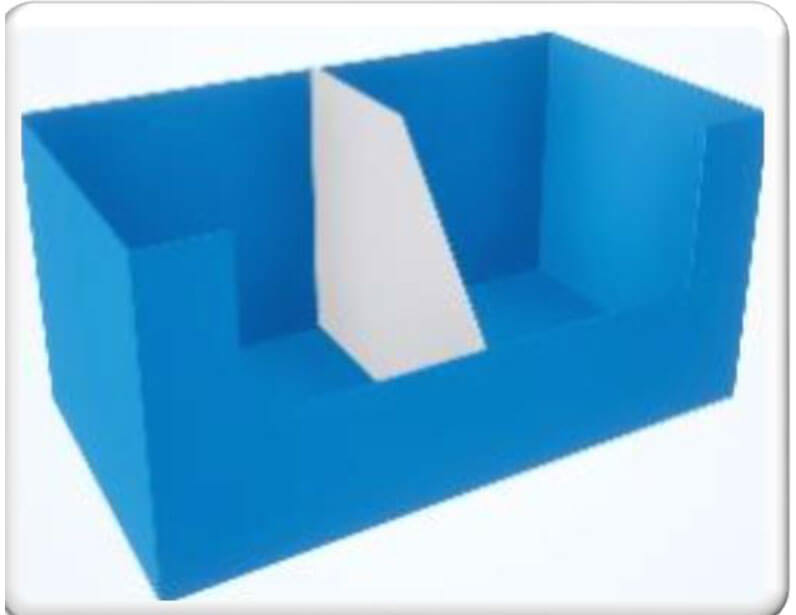

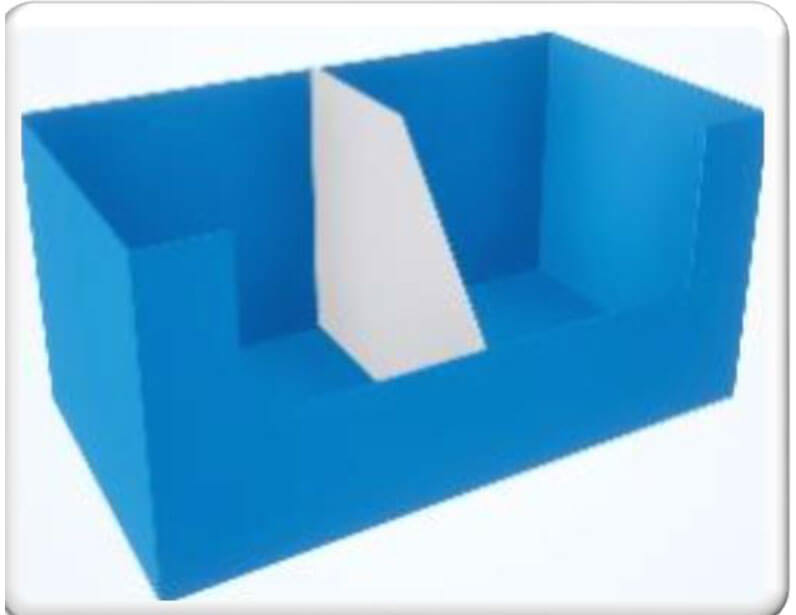

Center Divider

A center divider can be used to stop the front lip of a tray from failing, typically used with longer trays or heavy products.

Bumpers

Bumpers are formed when assembling the display and add stability, preferably for lighter weight products.

Sam’s Club Pallet Display Construction

Weight

-Total weight of tray/case should not exceed 50lbs. If it does, be sure to include the Team Lift Lable.

Product Accessibility

Trays should be stacked, display ready, so the pallet can be featured:

-Prefer pallets to be 3-side shoppable but consult category guidelines for exceptions

-Dividers should be utilized to contain vertically unstable product

-Displays and dividers should not result in product being trapped in the display or leave it unshoppable.

Material Selection

-Packaging must be designed so that it will withstand the supply chain.

Minimum Corrugate Board Grade

-200lb Mullen or 32 ECT B-Flute.

Sam’s Club Display Divider Guidelines

When dividers must be used to provide compression strength, selling units should not be trapped inside cases or blocked dividers.

Center Divider

A center divider can be used to stop the front lip of a tray from failing, typically used with longer trays or heavy products.

Die Cut Divider

A die cut divider can be added to a display to minimize side walls and increase product visibility. Die cut dividers should have windows so that all product is visible.

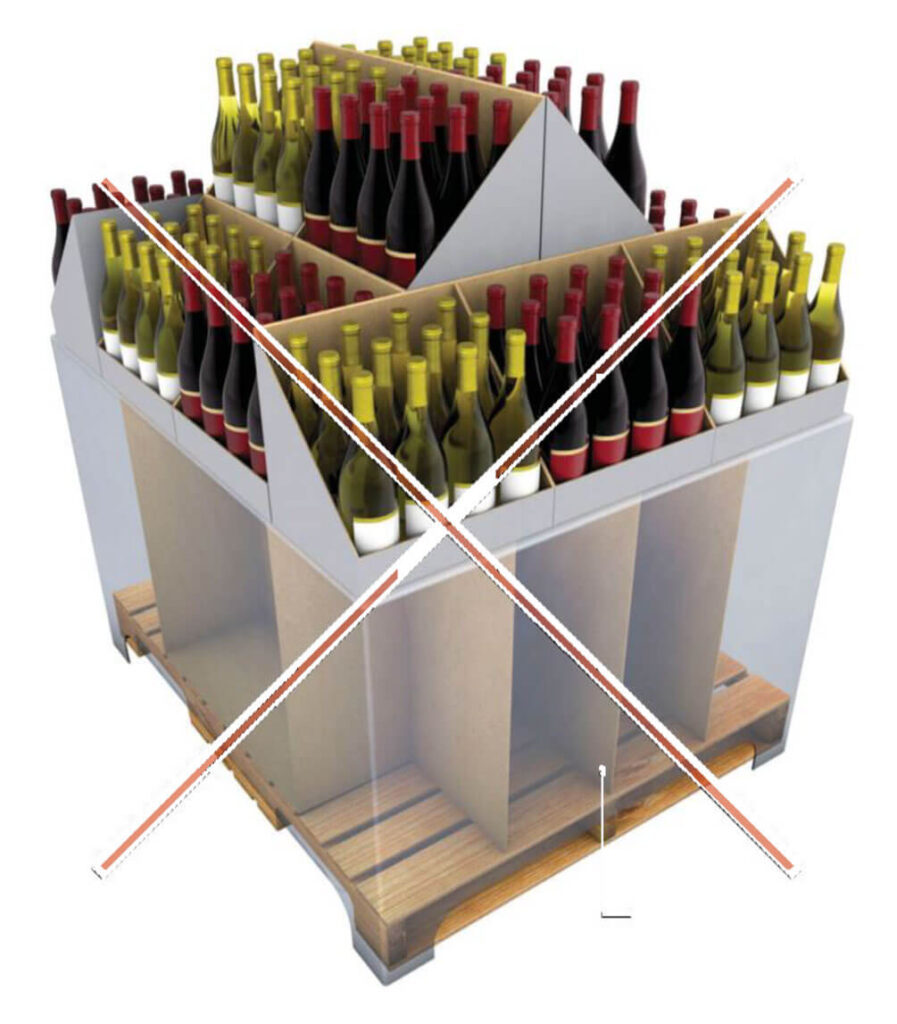

Poor Practice

Dividers should not be designed such that they block visibility when the front facing of product is sold.

Sam’s Club Pallet Display Configurations

All product must be able to support weight and pass the stacking requirements outlined in ISTA6-Samclub testing.

Max Weight

-Individual pallet load weight must not exceed 1133.98kg (2500lbs) including pallet.

Non-Palletized Freight

-Product will still be placed into pallet configuration at the Import DC. Supplier must provide the illustrated pallet pattern at the back of the load for Import DC to use.

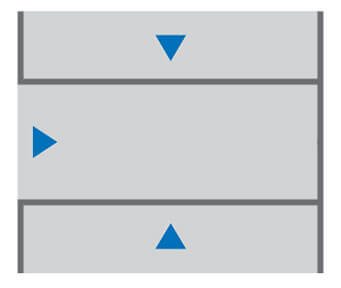

Shoppability(Member Facing Product)

Member should be able to remove product from all sides of pallet when displayed in an end cap or POD.

- 2 Sides Shoppable

- 3 Sides Shoppable

4 Sides Shoppable Undivided

4 Sides Shoppable Divided

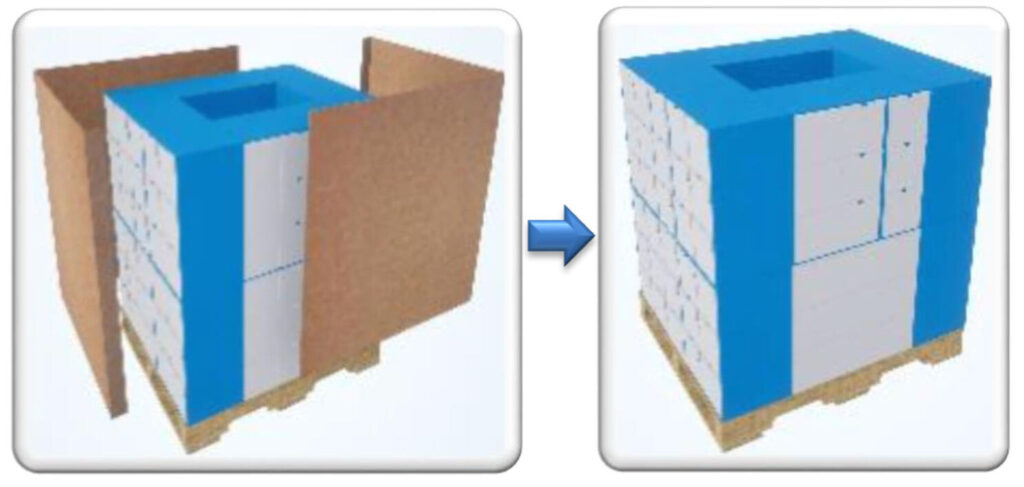

Club Ready Pallets/Units

All pallets must arrive club ready. After shipping materials (such as shrouds, corner posts, etc.) are removed from the pallet, the products are immediately sellable

Therr should be no additional handling by club associates

Items should also be easily replenished from the steel, without requiring hand-stacking.

False Buttoms and Chimmey

False Bottoms

False bottom pallets are strictly prohibited – No Exceptions.

A “false bottom” is defined as a unit with a designed air cavity under the merchandise that supports the unit above the floor level. False Bottom Pallets do not meet the structural guidelines and can result in structural failure. This could result in injury, loss of product and loss of life.

Chimneys and Void Space

When used, pallets must maintain stackability.

When Void Space exceeds 15% of the pallet footprint (up to 2sq.ft.), load bearing fillers are required.

Chimney should be located in the back center of the Pallet.

Sam’s Club Shipping Unit Dimensions

Height and Weight

- When shipping merchandise your first concern should be cubing out the container as long as the items can support the weight.

- Total hegith must not exceed 46.6”, during distribution.

- Suppliers are required to properly block and brace all shipments to withstand their rigors of transportation from their ship oint location to the IDC.

- Cases must be secured within the shipping unit.

- Do not use adhesive to glue cases together within shipping unit.

Fiber corner boards

- In order to increase recyclability, Sam’s Club strongly encourage the use of corner boards made of 100% plastic or 100% fiber. Mixed material corner boards such as composite or those with a metal or plastic interior and fiber exterior cannot be recycled from Sam’s DCs and clubs.

- Can be unwrapped (natural fiber) or wrapped (white)

- Prefer no logos or other colors

- No metal or composite materials

- Suppliers have the responsibility to ensure length, width and thickness of corner board is designed to properly protect and support the product.

Length and Width

- Merchandise must maximize the volumn of space allotted and limit the air space of the unit.

- MAXIMUM FOOTPRINT for CLUB-READY UNITS is 40.5”x48.5”

- Underhang is permitted: Up to 3” total (minimum footprint 37”x45”)

No overhang

Do not exceed 3” underhang

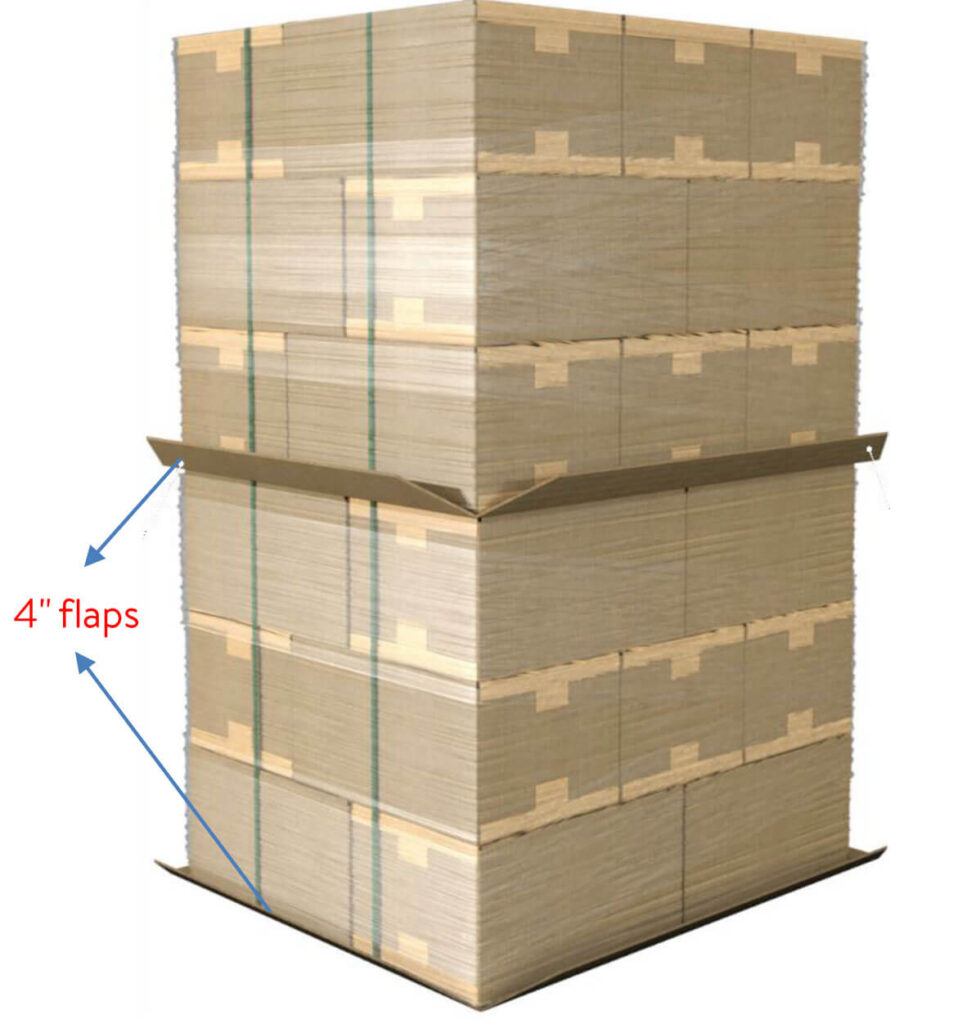

Sam’s Club Slip Sheet Guideline

Slip sheets for direct imports:

Unitized loads shipped on slip sheets to Sam’s distribution centers are allowed only under the conditions below.

- Slip sheets can be used for certain approved items when trailer cube utilization is a significant factor. If your item weighs out before it cubese out on a trailer, a pallet is requried.

- Slip sheets must have at least 4” flaps on two adjacent sides and be made of quality corrugated board, solid fiber, or plastic, which can be pushed or pulled repeatedly without damage.

- Use slip sheets that allow you to stack the merchandise on a 48.5”x40.5” footprint with no overhang so the load can be placed on a 48”x40” pallet and moved within the DC. Minimum footprint is 45”x37”.

- Stack merchandise on slip sheets as you would pallets using the same standards. Maximum height is 46.5”.

- The DCs will use slip sheet equipment to handle units that arrive on slip sheets. However, if the slip sheet is compromised or is of poor quality, be aware that clamping methods will be used.

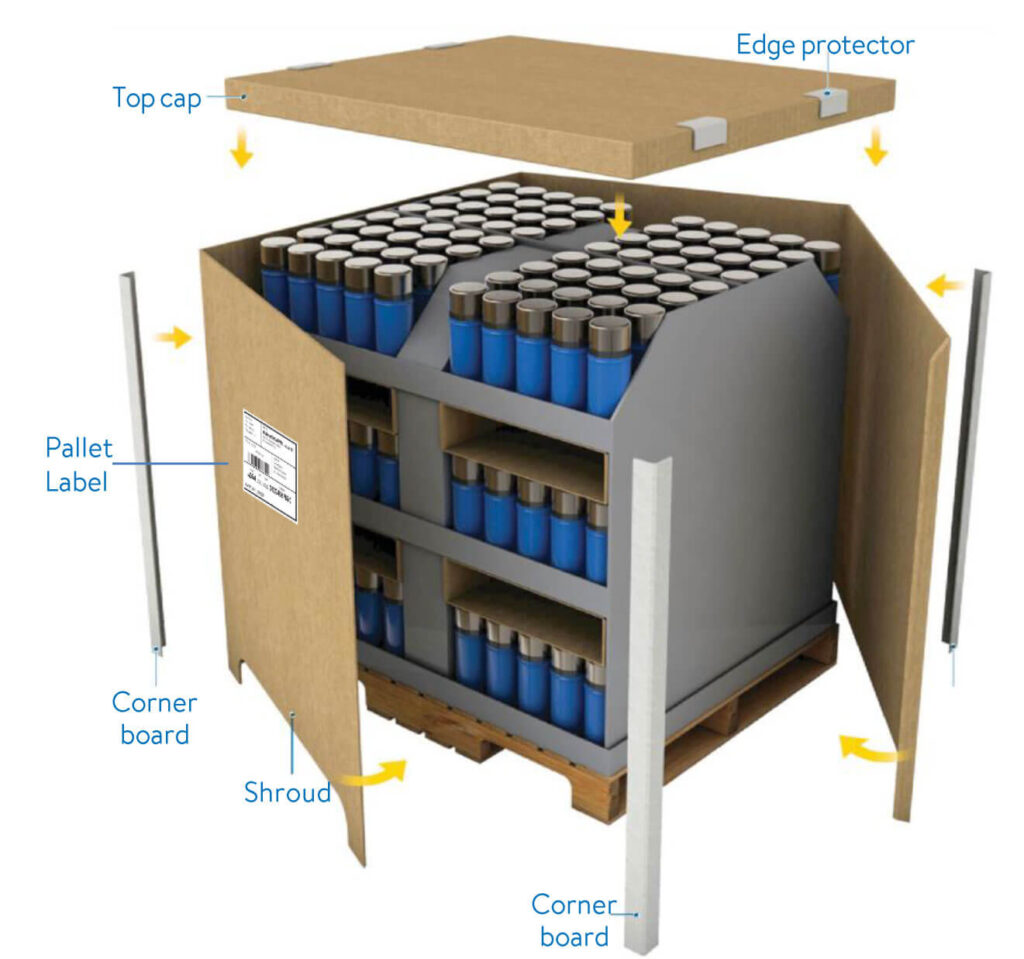

Sam’s Club Tertiary Packaging General Guidelines

- Do not tack heavy products on top of light products. Product must be stacked properly to avoid damages.

- Product stacked on pallets cannot be leaning or appear unstable.

- Product cannot be configured on the pallet such that it falls over when moved with a fork lift or when the stretch warp is removed while in the DC racks.

- Edge protectors are used to protect product from banding.

- A top cap and shroud are used for additional strngth, lateral stability, and stacking protection.

- The shroud height must be the exact height from floor to the top of the display. Leaving air space between the display and shroud can causing a collapse during shipment.

- Shrouds must withstand clamping pressure.

- Direct imports are often handled via pallet clamping.

- Use plastic straps to secure display ad shroud to pallet.

- Do not use metal bands, clasps or seals.

- Four fiber corner boards are used for additional stacking strength.

- Stretch wrap is used to keep all display components secure during shipping.

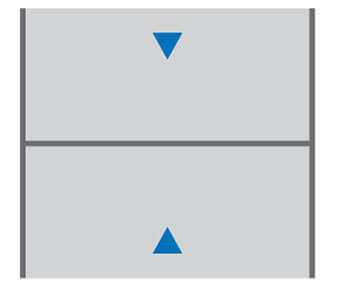

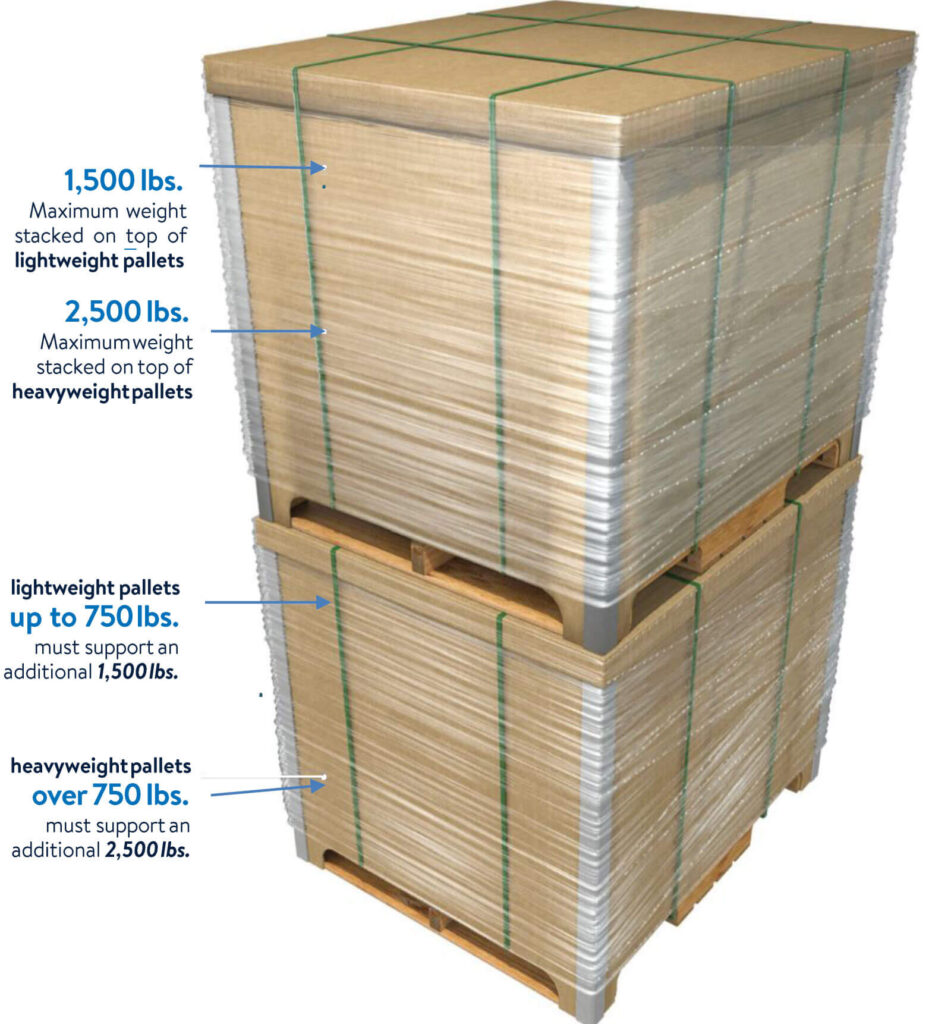

Sam’s Club Double Stacking

Double Stacking Outbound

- Sam’s Club will ship double stacked pallets in a trailer from DCs to clubs

- Product will be double stacked, possibly with heavy product on the top of the stack.

- It is not acceptable for pallets to be lableed “DO NOT DOUBLE STACK” or any similar verbiage.

- Product must be designed to double stack. Even if your product weighs out a truck, it will be double stacked somewhere ini the supply chain.

Lightweight pallet

Pallet configurations weighinig under 750lbs.

- The bottom layer of the pallet must be capable of supporting an additional 1500 lbs. without crushing, bending or tearingn the merchandise or packaging throughout the entire supply chain process.

Heavyweight pallet

Pallet configurations weighing over 750lbs.

- The bottom layer of the pallet must be capable of supporting an additional 2500lbs. without crushing, bending or tearing the merchandise or packaging throughout the entire supply chain process.

- Individual pallet load weight must not exceed 2500lbs., including pallet.

Costco Supply Chain Handling

Costco manages a multifaceted supply network. Costco’s Supply Chain Handling briefly explains the handling processes for the following distribution channels:

- Inline – Depot to Warehouse

- Online – Ecommerce

- Big and bulky: Receiving facility to staging facility/facilities to final-mile delivery

- Small pack: Depot to Member

- Drop ship: Supplier to Member

It’s important to understand these channels to engineer packaging that will maintain its structural integrity throughout Costco’s entire supply chain.

Merchandise Handling Equipment

Merchandise is handled at Costco’s receiving facilities and Warehouses using many different types of equipment. Anticipate that your items will be handled by one or more of the illustrated examples.

Inline: Depot to Warehouse

Costco’s Depots are managed and most efficiently operated as cross-dock facilities. We strive not to hold or store inventory at our Depots.

Receiving

Palletized product will be offloaded using a forklift or electric pallet jack (EPJ).

Floor-loaded product will be offloaded and palletized using a mechanical clamp truck. The clamp truck panels will press against the sides of the goods that are parallel to the long sides of the container. Slip sheets are not to be used under floor-loaded product; they interfere with the unloading process.

Warehouse Distribution

Product is shipped to Warehouse locations on the same day. Full pallet distribution is cross-docked immediately.

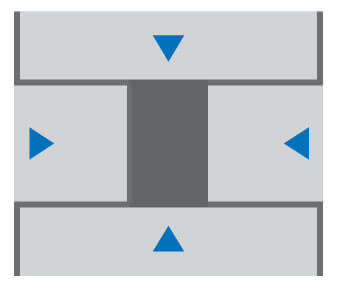

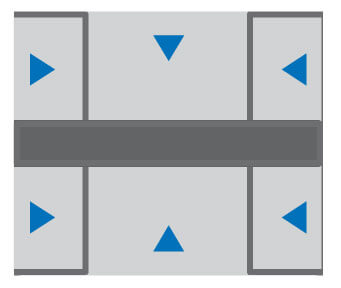

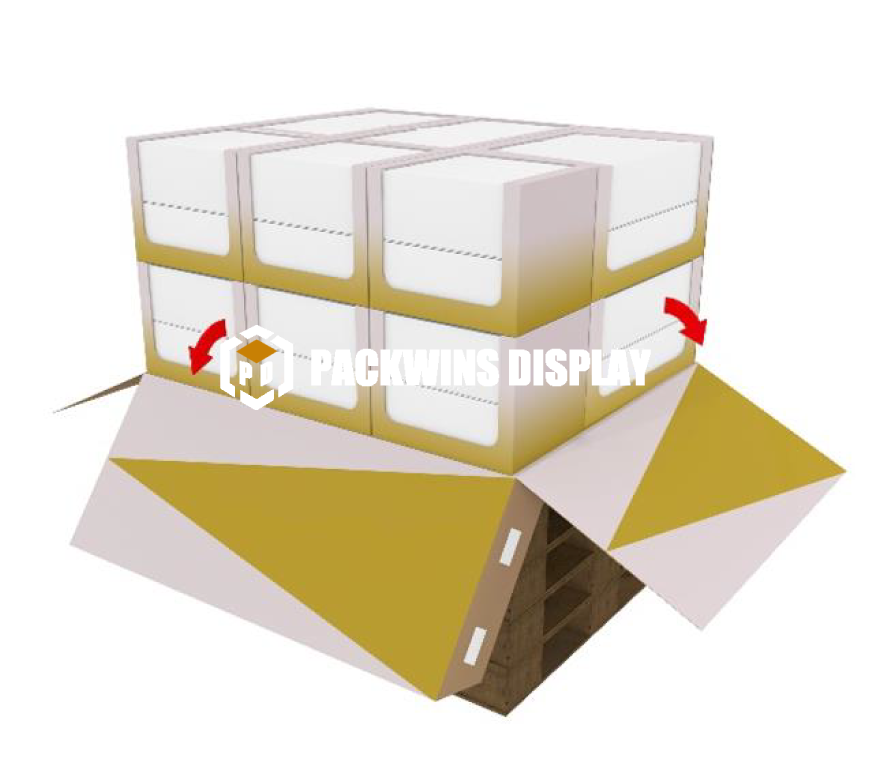

Product distributed to our Warehouse locations in less than full pallet quantities requires mechanical clamping to sort layers of product. Layers may be clamped multiple times during this process. We utilize both two-way and four-way clamp trucks, so clamp panels may press against the 40″/101.6 cm sides, the 48″/121.9 cm sides or all four sides. (Fig. A & B)

Clamped layers are set onto separate pallets. Multiple items are stacked together for outbound shipment. (Fig. C)

Confirm distribution plans with your Costco buyer to determine whether your packaging needs to be designed to support clamping for layer distribution.

2-way Clamping

Clamp truck panels press against two sides of load.

4-way Clamping

Clamp truck panels press against all sides of load.

Outbound Mixed Pallet

Warehouse Handling

Costco warehouses are the physical locations where our members come to shop. They merchandise inventory on 48″ x 40″/121.9 cm x 101.6 cm pallets.

Pallet loads of product are moved into place by forklifts or pallet jacks. Anticipate that pallet loads will be multistacked during receiving, and in cooler or freezer storage.

Additional product for daily replenishment is stored in the steel shelves above the pallet run.

As product shops down, pallets are refreshed, and empty trays are removed and reused on the Front End for members to carry out their purchases after checkout.

Ecommerce for Big and Bulky Items

USA –Direct Distribution Center (DDC) and Market Delivery Operation (MDO)

Canada – Depot, Induction, Mid-Mile and Final-Mile Facilities

Receiving and distribution for online orders of big and bulky items occurs through Costco’s distribution network.

Most merchandise is received floor loaded and moved without pallets throughout Costco’s distribution channels using mechanical clamp trucks. Limited product lines received on previously approved, purpose-built pallets will be moved using forklifts, electric pallet jacks and/or mechanical clamp trucks.

DDC/Depot

Big and bulky items are delivered to our DDC/Depot locations.

Product that arrives floor loaded will be offloaded using a mechanical clamp truck. The clamp truck panels will press against the sides of the goods that are parallel to the long sides of the container. Slip sheets are not to be used under floor-loaded product; they interfere with the unloading process.

Goods will be stacked upon themselves and may be stored for up to one year to support online orders.

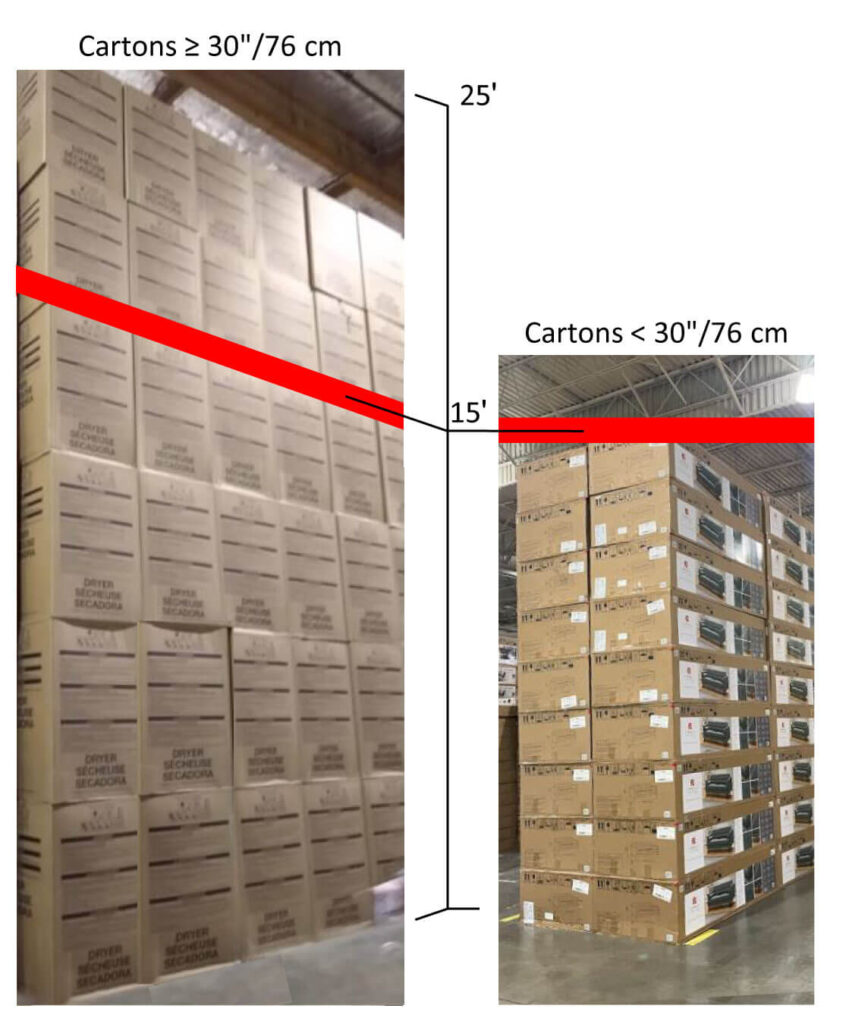

| Carton Height | Will be Stacked |

|---|---|

| 30″/76 cm or taller | at least 15’/4.6 m up to 25’/7.6 m |

| less than 30″/76 cm | up to 15’/4.6 m |

Handling graphics (pictograms) are required on all items distributed through our big and bulky delivery network.

Ecommerce for Small-Pack Items: Depot to Member

In the USA once an online order is placed for a big and bulky item, it ships from the DDC to the MDO. Once received, the MDO stages product for our final-mile carriers to load into their delivery trucks. Some items may be unboxed and assembled prior to staging.

In Canada once an online order is placed for a big and bulky item, it ships from the Depot to a third-party induction facility for sorting. Once received, the induction facility stages product to ship to either a mid-mile facility or final-mile facility for final-mile carriers to load into delivery trucks. Some items may be unboxed and assembled prior to staging.

Delivery may include:

- Hand truck

- Moving dolly

- Moving straps

Ecommerce for Small-Pack Items: Depot to Member

Some Costco Depot facilities receive, process and ship small-pack Ecommerce items to fulfill orders purchased through our ecommerce platforms.

Receiving

Palletized product will be offloaded using a forklift or electric pallet jack (EPJ).

Floor-loaded product will be offloaded and palletized using a mechanical clamp truck. The clamp truck panels will press against the sides of the goods that are parallel to the long sides of the container. Slip sheets are not to be used under floor-loaded product; they interfere with the unloading process.

Storage

Palletized goods may be stored at the Depot for up to one year to support online orders and may be stacked up to 25’/7.6 m.

Delivery

Once an online order is placed, items are processed for delivery and floor-loaded onto a 53’/16.15 m trailer to be transported to a small-package delivery service for final-mile delivery.

Ecommerce Drop Ship: Supplier to Member

Based upon what’s been negotiated between Costco and the supplier, some Ecommerce items are shipped from the supplier directly to the member.

Drop-ship items must be designed to arrive safely to our member without damage.

It is the supplier’s responsibility to determine how this is accomplished, whether the item ships in its original package or in an overpack.

Costco Package Engineering & Performance Requirement

Minimum Package Engineering Requirements

Packaging must be engineered to withstand the following standards, under load weight, without failing:

- Item-appropriate International Safe Transit Association (ISTA) pre-shipment tests, freight carrier rules and government regulations that are mandatory within their respective jurisdiction (www.ista.org)

- Long-haul transit dynamic load factors (over 500 miles/804 km) without damage

- Repeated forklift, pallet jack and up to 2,300 psi/159 BAR mechanical clamping, without damage

- 80% to 90% high-humidity environmental conditions

- A minimum of four weeks’ storage time

- Packaging for cooler/freezer products must be able to withstand refrigerated temperatures in a moist environment

- Moisture Resistant Adhesive (MRA) is required for all corrugated packaging that is exposed to a moist, refrigerated environment, and recommended for non-refrigerated environments

- Expanded polystyrene is not allowed. Packaging component materials should be widely recyclable or certified compostable by members in the areas where the product will be sold. Exception: If an alternative material cannot sufficiently protect the product and polystyrene is required, it must have a minimum foam specification of 20 kg, and be clean, high quality and high impact that does not break apart or pill.

Additional Package Engineering Requirements for Ecommerce Big and Bulky and Small-Pack Product.

- Stacking up to 25’/7.6 m high, and vertically stable independent of any external structural support (refer to Sections 1.4 and 1.5 for details)

- Up to 2,300 psi/159 BAR mechanical clamping 15 or more times, without damage

- Up to one year storage time (after being received by Costco)

- Stack lean may be no greater than 3% of the total stack height

Confirm distribution plans with your Costco buyer to determine whether the packaging for your item needs to support additional Ecommerce requirements.

Conventional testing typically cannot predict failures within our robust supply chain. Engage the expertise of a packaging engineer versed in designing for our environment to ensure your packaging meets Costco’s supply chain requirements.

Minimum Dynamic Stacking Strength Requirements

Each pallet load under 750 lbs./340 kg (including pallet) must be capable of withstanding 1,500 lbs./680 kg of weight on the bottom product layer without damage.

Each pallet load weighing 750 lbs./340 kg (including pallet) or more must be capable of withstanding 2,500 lbs./1134 kg of weight on the bottom product layer without damage.

Pallet loads must maintain stacking strength and stability during end-aisle (end cap) or focus-area sales floor merchandising no less than 6’/1.8 m tall, regardless of unit load height inbound to Costco.

To determine overall packaging performance requirements, include environmental factors in Section 2.1.

Essential Packaging Functions

It is expected that the packaging performs several functions during transportation, storage, display and use, including:

- Containment of the product to ensure integrity and safety

- Protection of the product from physical damage

Some examples include:

- Orienting goods inside cartons to support stacking on top of largest outer box surface, or top surface for goods with directional stacking requirements (e.g., TVs)

- Designing cartons with vertical corrugation (fluting) per the stacking orientation

- Using supportive packaging inside of outer carton (dividers, inserts, etc.) that supports the stacking orientation

- Convenience of use and ease of handling

- Compliance to legal and regulatory requirements

Performance Testing is Strongly Recommended

The purpose of testing products is to ensure that packaging quality is sufficient to withstand the rigors of transit, delivery and storage within the Costco network and to our members.

- Performance testing will reduce damage, rework and returns, and will improve the member experience

- Professional associations and regulatory bodies, such as International Safe Transit Association (ISTA) may offer pre-shipment test procedures, which provide a means to determine the probability of the safe arrival of a packaged product at destination

While ISTA ship testing helps to predict whether the packaging or packaging material is optimal for shipment through the supply chain, it does not guarantee damage-free shipments.

Ultimately, it remains the supplier’s responsibility to ensure that their product is properly packaged so it arrives to the member in good condition.

Costco Pallet Load Requirements

Unit Load & Pallet Load Configuration

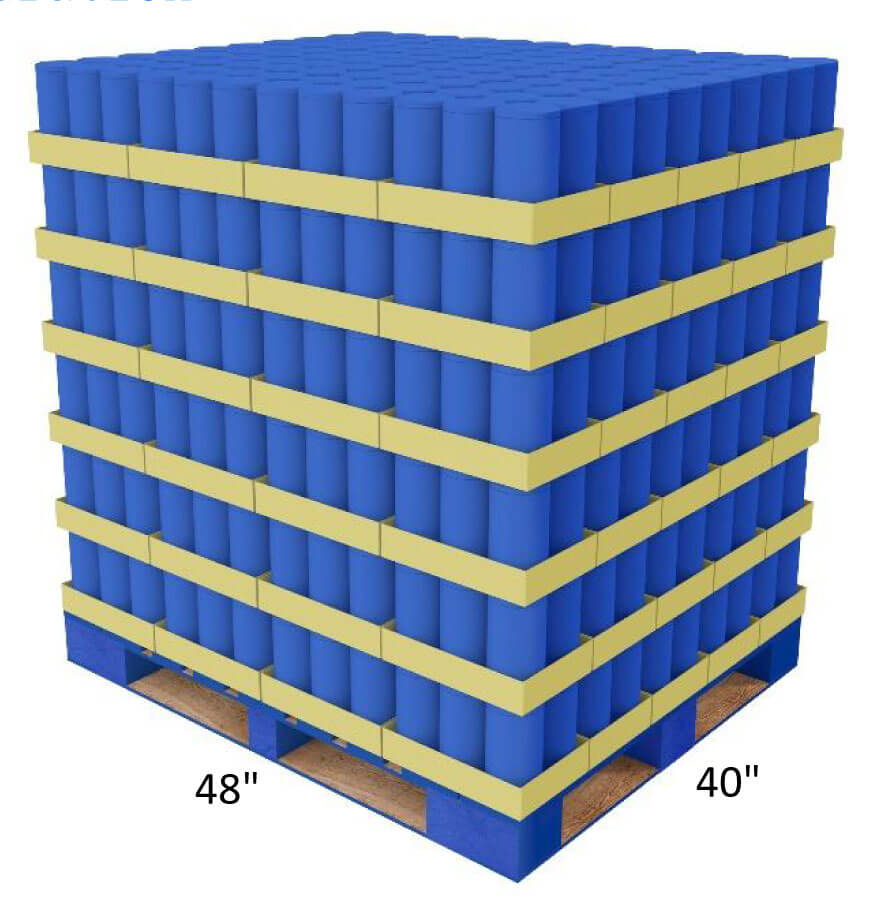

Unit load footprint must not exceed 48″ x 40″/121.9 cm x 101.6 cm, and cannot be smaller than 45″ x 37″/111.8 cm x 94 cm. Overhang is prohibited.

Recommended footprint is 47″ x 39″/119.4 cm x 99.1 cm.

Exceptions are made only for oversized goods.

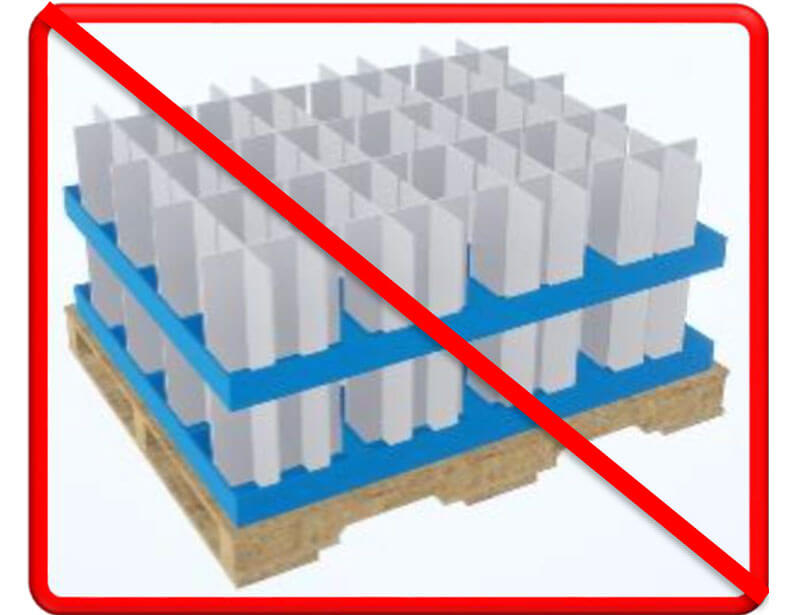

Unit load must maximize pallet area without gaps between sell units or master cartons. (Fig. A)

Chimney stacking is prohibited. (Fig. B)

False bottoms that ship with empty space below goods are prohibited unless requested by Costco. (Fig. C)

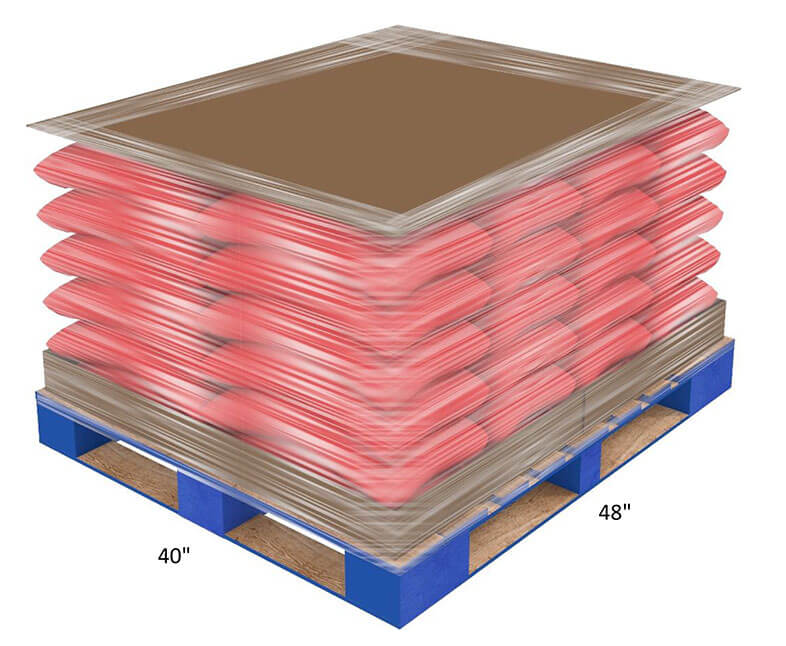

Use layer pads or grip sheets for stability of small footprint sell units.

Primary packaging and display trays or master cartons must be designed to fit properly on pallets.

Costco encourages reverse engineering to ensure a proper fit.

Costco Unitized Pallet Requirements

Pallet Layout Guidelines

The 48″/121.9 cm pallet dimension is the main shopping side.

Design the pallet layout to support the following merchandising requirements:

A. Dry items merchandised on pallets

a. A pallet oriented on three or all four sides is preferred as it provides the greatest flexibility for end cap merchandising (Fig. A)

b. At a minimum, orient goods to face one 48″/121.9 cm side and at least one 40″/101.6 cm side for inline and end cap merchandising flexibility

B. Cooler/freezer items merchandised on pallets

Orient goods to face one 48″/121.9 cm pallet side

C. Items not merchandised on pallets (deli, books, etc.)

Goods may be palletized facing any direction

Column stack to optimize stacking strength.

Oversized goods and goods with multiple boxes per sell unit should be palletized with the largest box/portion of the box in the center of the pallet and the heaviest box/portion of the box on the bottom.

Unitized Requirements for Goods Shipped in Fully Enclosed Corrugated Cartons

Pallet load weight (including pallet) must not exceed 2,500 lbs./1134 kg.

Packaging and unit load height must support double stacking in transit whenever our Warehouse receives full unit load quantities and for Ecommerce. (If double stacking exceeds shippable weight limits, total pallet load height may be up to 58″/147 cm, including pallet height.)

If the Costco buyer has indicated distribution to Warehouses will be done in layers, unit load height is limited only by the loadable height of inbound shipping equipment.

Contain the unit load, and secure it to the pallet with stretch film or strapping. Stretch film must be uncolored, minimum of 0.79 mil, and wrapped three times or the performance equivalent.

No metal strapping, no metal buckles, no stretchable tape and no netting.

CAUTION: Anticipate shipping and handling dynamics to ensure unit loads will still be properly contained and secured to the pallet at delivery.

Unitized Requirements for Goods Shipped in Display-Ready Packaging

Use non-skid coated paper sheets to stabilize and “tie” layers together. When possible, avoid using corrugated sheets between layers. Do not use layer caps.

Use a layer pad or cap atop unit loads to protect goods in open-top display trays.

Use paper/fiber corner posts only if necessary. Plastic corner posts are prohibited.

Vertically unstable goods with multiple units per unit load (tall rugs, mirrors, brooms, etc.) must use supports to prevent partially full pallet loads from tipping over on our sales floor.

Stretch film or strapping must not damage display trays or consumer packaging.

Unitized Requirements for Bags Exceeding 10 lbs./4.5 kg

Pallet load weight must not exceed 2,500 lbs./1134 kg (including pallet).

Pallet load height must not exceed 50″/127 cm (including pallet).

A pallet tray is required between the bottom layer and the pallet, and a layer sheet or tray is required atop the unit load.

Unit load must be contained and secured to the pallet in one of the following ways:

- A. 1.2 mil one-side-cling, puncture-resistant, uncolored stretch film. At least three layers of film should cover the top third and bottom third of the pallet load. The unit load must be securely attached to the pallet.

- B. Corrugated shroud fully enclosing the unit load. Stretch film should cover from top to bottom and be secured to the pallet.

CAUTION: Anticipate settling during shipping and handling. Ensure the unit loads remain properly contained and secured to the pallet upon delivery.

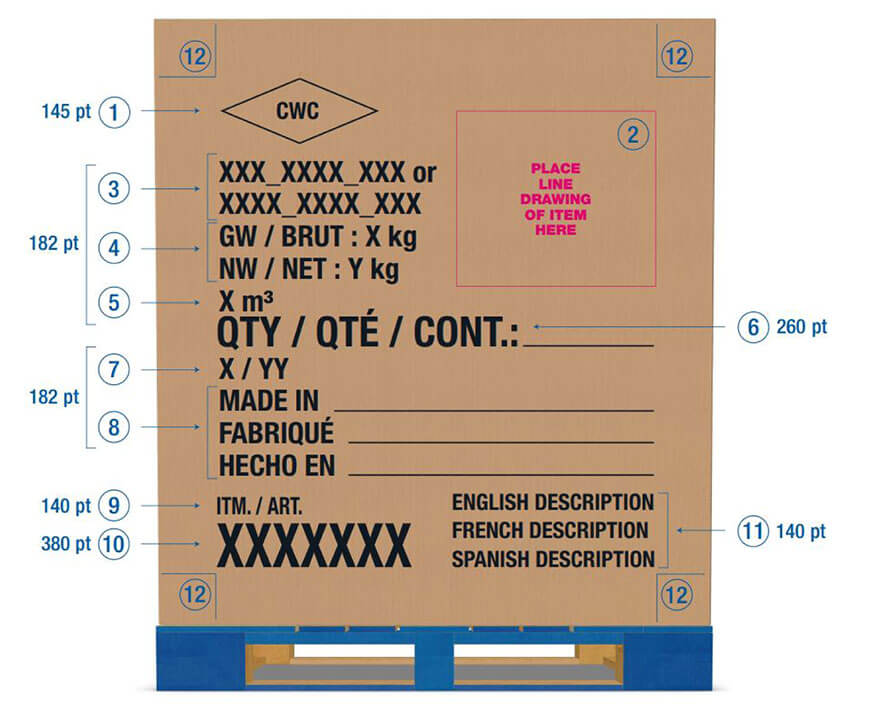

Identification Markings for Goods Shipped in Fully Enclosed Corrugated Shrouds

Markings improve warehouse efficiency and help operators easily identify the product.

Both imported and shrouded domestic items are required to have identification markings printed on the front-facing 48″/121.9 cm panel.

Markings should:

- Utilize the full space on the panel.

- Be printed in black, using Helvetica Neue LT Std 77 Bold Condensed font in the appropriate size for each section (see the template on the following page).

Your Costco Buyer must review and approve all packaging prior to printing.

Template based on a 48″ x 52″/121.9 cm x 132 cm panel. Markings should be scaled accordingly if working with a different sized panel.

Template Key:

- CWC = Costco Wholesale Corporation

- Product line drawing

- Costco Purchase Order number

- Gross/Net Weight – noted in both English and French (kg)

- Gross cubic meters

- Pallet sell unit quantity

- Pallet sequence with container/truckload (e.g., 1/60, 2/60…60/60)

- Country of origin – noted in English, French, and Spanish

- ITM./ART. = Item/Article

- Costco Item number

- Basic product description

- Imported item noted in English, French, and Spanish

- Domestic item noted in English only

- Margin (5″ on all sides)

Costco Package Design

Sell Unit Packaging

Rigid sell units that provide stacking strength are ideal to enhance product visibility, facilitate easy shopping, and minimize overall packaging.

Gusseted and squared bags (self-standing bags) are optimal for the best display and use of space. When possible, flexible films should be made from mono-materials that are widely recyclable.

Product packaging can ship without the use of a secondary display tray if it is:

- Self-supporting

- Able to be unitized into a stable pallet load and designed to ship without damage

- 7.5″ x 7.5″ x 7.5″/19 cm x 19 cm x 19 cm or greater in size

- Designed to withstand mechanical clamping if distributed in layer quantities (Refer to Section 2)

- Able to support product weight without buckling, independent of the structural support of corner boards or other ancillary shipping components

Bottle closures must have adequate stacking strength if self-supporting.

Reverse-engineering is encouraged to facilitate a successful pallet load footprint.

Sell Unit Packaging –Blister

Costco prefers paper card and trapped paper card packaging.

Written approval from the buyer is required to use card-and-blister (trapped blister), or stretch card (stretch pack) packaging.

Blister box (box-and-blister), blister card (face seal, skin board, or mock clamshell), or clamshells (two-piece blister packs) are not allowed.

All packaging component materials should be widely recyclable, certified compostable, or biodegradable by members in the areas where the product will be sold.

Costco must approve packaging for look and feel prior to retail placement. This approval is for aesthetics only and not structural integrity.

Plastic must be thick enough to hold product(s) securely and have great clarity.

Not acceptable:

- Rigid PVC

- Plastic with cracking and/or sharp edges

- Clamshells/two-piece blister pack

- Blister box/box-and-blister

- Blister card/face seal

Exceptions to these requirements are produce clamshells or unit-dispensing blister cards (pharmacy and chewing gum).

Acceptable Packaging Types

Not Acceptable Packaging Types

Sell Unit and Display Tray Integration

Display tray and sell unit packaging should be designed to work together for product protection and merchandising.

Display tray design considerations:

- If the product packaging (the sell unit) does not provide any structural support, design the tray to carry all load weight (pouches, bags, soft goods, etc.).

- If the product packaging is partially stable, but not strong enough to support all load weight, design the tray to work with the sell unit, so together they provide the proper strength.

- If the product packaging supports the load weight and is smaller than 7.5″ x 7.5″ x 7.5″/19 cm x 19 cm x 19 cm, include a low wall tray for containment (Fig. A).

Display Trays – Style and Function

For items merchandised on a pallet or shelf, ship products in a display tray only if necessary for unit load stability or to protect the product from damage.

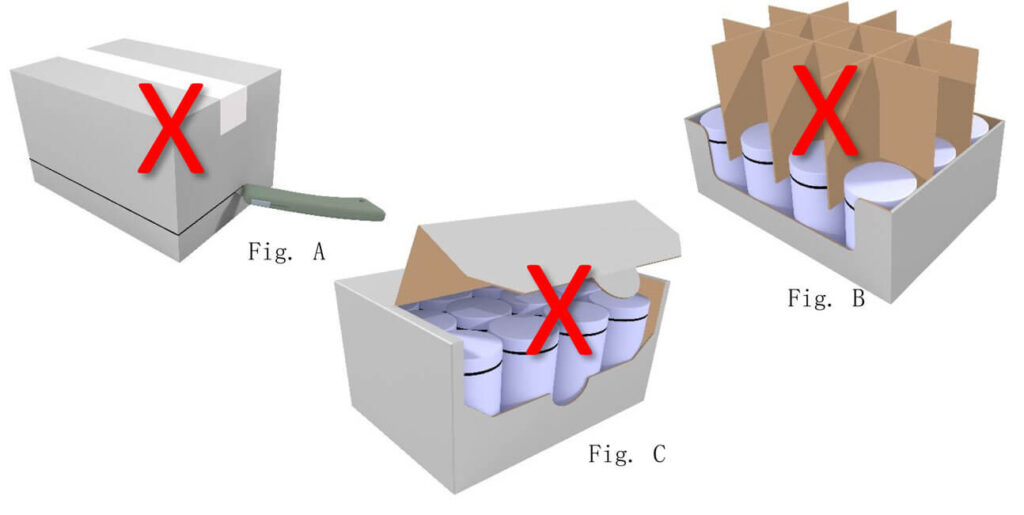

Must ship display-ready, without box cutters or labor required to stock product (Fig. A).

Display trays should support the product inside without product blocking dividers (Fig. B).

Tear front panels (Fig. C), plastic strapping, tear tape, telescoping lids, and tray covers are not allowed.

Exceptions:

A. Telescoping lid or display tray cover may be used if products are distributed in layer quantities.

B. Products distributed in individual case quantities may be shipped in a display tray with a telescoping lid taped to the bottom on two opposing sides.

Product containment inside the tray must support Costco distribution method. Confirm distribution plans with your buyer to determine whether distribution will occur by pallet, layer, or individual cases.

Maximum weight cannot exceed 40 lbs./18 kg per tray. Recommended case weight should not exceed 25 lbs./11 kg.

Display tray presentation is as important as sell unit presentation at the point of sale. Consider the interaction of tray and sell unit packaging for the best presentation.

Display Trays – Design Specifications

Incorporate a design feature that prevents the tray above from nesting into the tray below.

Stacking tabs to interlock layers, which hinder the process of inventory replenishment, are allowed only for produce items.

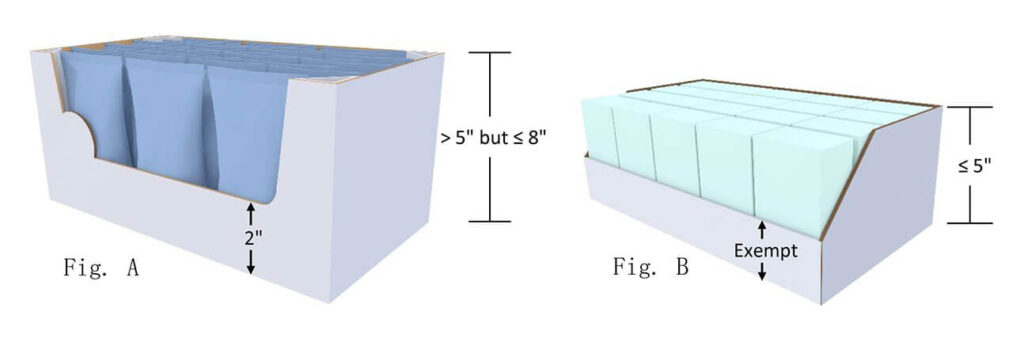

Trays must have a minimum of 3″/8 cm front panel height unless one of the following is true:

- For product that is single stacked with a height greater than 5″/12 cm but less than or equal to 8″/20 cm, the minimum front tray height may be reduced to 2″/5 cm, as long as the remaining three sides are a minimum of 4″/10 cm (Fig. A).

- For product that is single stacked with a height less than or equal to 5″/12 cm, the tray is exempt from the minimum front height requirements (Fig. B).

Product bearing 100% of load weight may be contained using a low tray, provided it meets the minimum front panel height requirements.

When there are multiple sell units per tray, size trays to five per layer minimum to support Front End reuse.

Use of large 48″ x 40″/121.9 cm x 101.6 cm pallet trays is allowed only:

- When there are 24 or fewer sell units on a layer.

- If Costco deems goods to be very high volume, e.g., chips, salty snacks.

Costco Master Case Requirements

Fully Enclosed Master Cases

Certain categories, such as apparel, books, and service departments (Meat, Bakery, Food Court, and Service Deli) that are not merchandised on a pallet or shelf, may be shipped with multiple sell units in an enclosed master case.

Maximum weight should not exceed 50 lbs./23 kg when the master case is of the size to be hand lifted. If the master case exceeds 50 lbs./23 kg, it must be marked with a Heavy Weight/Multiple-Person Lift pictogram.

Wax-impregnated boxes are allowed only on fully enclosed master cases. Wax-coated cases that prohibit recycling are not allowed.

Costco Display Pallet Guidelines for Special Circumstances

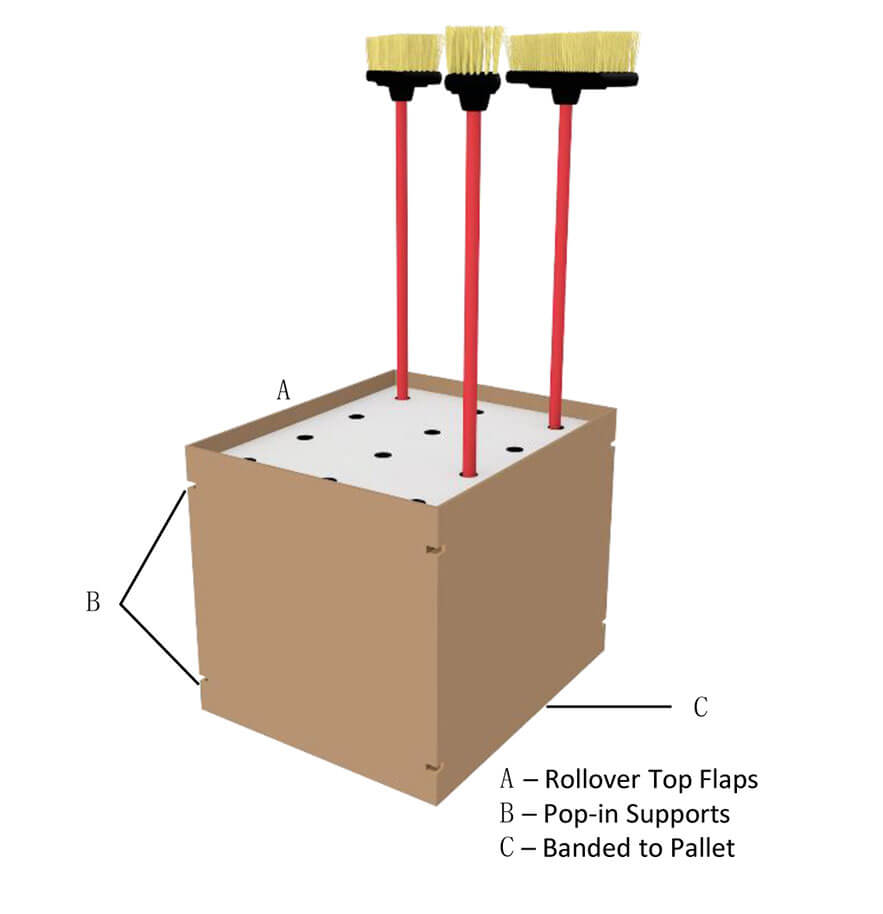

Master Display Requirements with Pop-In Tray Supports (E.g.: mops, brooms, pruners, shovels)

Regular Slotted Container (RSC) bottom with 2.25″/5.7 cm rollover top flaps and pop-in tray supports in all four corners. 44 ECT/275 lb. Mullen test board, C flute minimum requirement.

Double wall recommended for pruners and shovels.

Two corner-cut trays with die-cut holes at the top and bottom to ensure vertical pole stability.

Each master displayer must be banded to its pallet so the displayer cannot tip off the pallet in transit or on our sales floor.

A corrugated shroud may be necessary for stability and protection of the goods in transit and during handling.

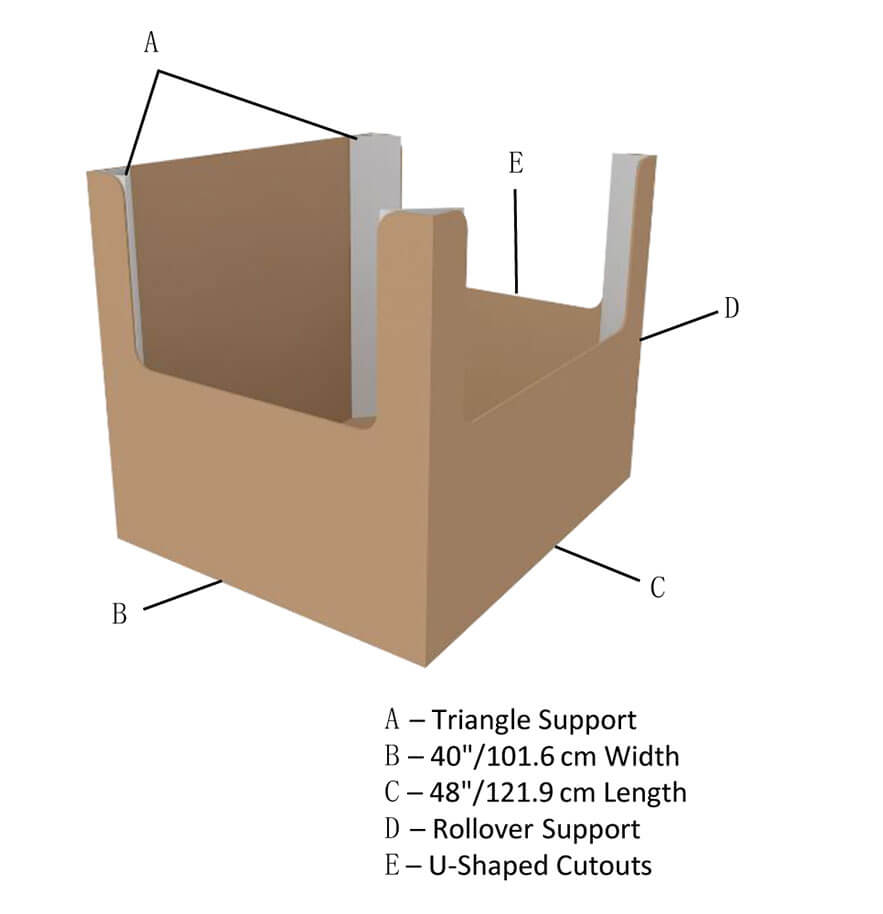

Bulk Bin Requirements (E.g.: pet beds or throws, and pillows)

44 ECT/275 lb. Mullen test board, C flute minimum requirement.

Double wall recommended.

Bulk bins must have U-shaped openings on the front 48″/121.9 cm side and two 40″/101.6 cm sides. Tear panels are restricted. U-shaped openings must not exceed 50% of the front panel height. Cutouts must have full depth rollovers for enhanced panel strength.

Inner triangular corner supports fastened or adhered to inside four corners are required.

Corrugated shroud and a deep-skirt pallet cap are required to completely enclose the unit load.

Corner posts and two belly bands are recommended.

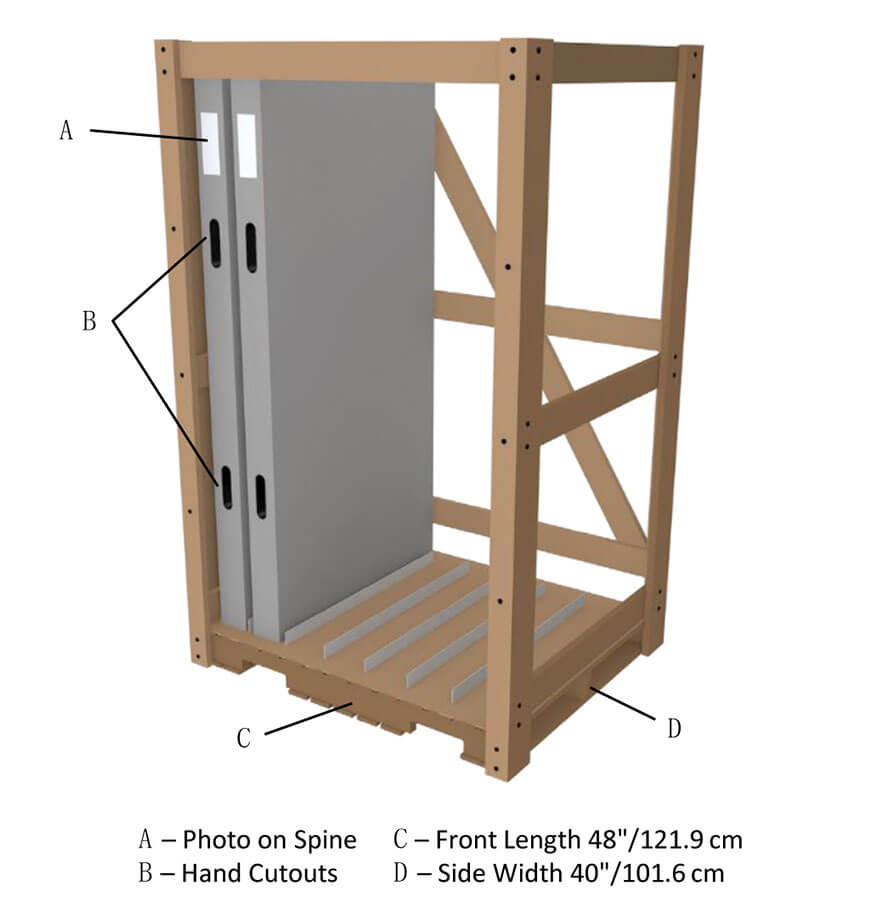

Wood Pallet Side-Load Crate Requirements (E.g.: large mirrors and framed art)

Products must be shipped in a wood crate with dividers or plastic runners at the top and bottom to separate and secure products in place.

The wood crate must be attached to a 48″ x 40″/121.9 cm x 101.6 cm wood pallet that meets Costco’s wood pallet requirements. (Refer to Pallet Specifications reference pages.)

A header label is required to show the assortment. Each item must be identified with a photo sticker or illustration on the spine.

A plastic strap handle or reinforced hand cutout must be added to each item for accessibility to slide the product in and out of the pallet crate.

Metal Frame Rack Requirements (E.g.: rugs)

Racks should be manufactured using a welded or bolted metal frame designed to prevent lateral movement of the unit load. Diagonal rigidity should be incorporated into the design.

Racks should be designed with channels or product supports at the top to separate and secure the products in place, and to prevent the product from creating a leaning, top-heavy unit load.

Racks must be attached to a 48″ x 40″/121.9 cm x 101.6 cm wood pallet that meets Costco’s wood pallet requirements (refer to Pallet Specifications reference pages), using a minimum of four 3/16″ x 3″ lag screws/bolts fastened over the corner or side blocks with a minimum fastener penetration of 1.5″/3.8 cm into the wooden block.

False-Bottom Display

Allowed only if directed by your Costco buyer.

Allowed only for over-the-counter (OTC) Pharmacy items.

Corrugated skirt not to exceed 26″/66 cm high (not including base pallet).

Skirt to be pre-built prior to shipment and must adequately support the product above during shipping and merchandising.

Display height must be a minimum of 52″/132 cm, and a maximum of 60″/152 cm (not including base pallet).

Fillers between trays of product are acceptable to achieve overall display/presentation.

Must be shoppable on three sides (one 48″/121.9 cm and two 40″/101.6 cm) unless written approval is obtained from the buyer.

Do not wrap or cover individual trays.

Pallets must be placarded as “False-Bottom Display, Do Not Double Stack”.

Butterfly Skirt Display

Allowed only if directed by your Costco buyer.

Corrugated skirt height = 22″/55 cm.

Straight base (no cutouts).

Display height to be 52″/132 cm (not including base pallet).

Fillers between trays of product are acceptable to achieve overall display/presentation.

Must be shoppable on three sides (one 48″/121.9 cm and two 40″/101.6 cm) unless written approval is obtained from the buyer.

Compare and Conclusion

Pallet Specifications

Standard Dimensions:

48″ x 40″ pallets are used in both Sam’s Club and Costco.

Height Restrictions:

Costco: Maximum 58″ in-store; 52″ for double stacking.

Sam’s Club: Maximum 60″ in-store; 52″ for double stacking.

Weight Capacity

Costco: Supports up to 2,500 pounds.

Sam’s Club: Supports up to 2,100 pounds.

Design Techniques

Reverse-engineering is encouraged to facilitate a successful pallet load footprint.

Leverage strong branding with consistent colors and logos.

Use the “billboarding” technique to create an impactful visual impression.

Explore creative options such as pallet board store display ideas or pallet box trade show displays for unique setups.